751.32 Concrete Pile Cap Intermediate Bents

751.32.1 General

751.32.1.1 Material Properties

| Concrete | |||

|---|---|---|---|

| Typically, shall consist of: | |||

| Class B Concrete (Substructure) | = 3.0 ksi | ||

| = 10 | |||

In addition, Class B-1 Concrete (Substructure) may also be used in special cases (See Project Manager). The following equations shall apply to both concrete classes:

Concrete modulus of elasticity:

Where:

| = unit weight of non-reinforced concrete = 0.145 kcf | |

| = correction factor for source of aggregate = 1.0 |

| Modulus of Rupture: | For minimum reinforcement, | |

| For all other calculations, | ||

| is in units of ksi |

Reinforcing Steel

| Minimum yield strength, | = 60.0 ksi | |

| Steel modulus of elasticity, | = 29000 ksi |

751.32.2 Design

751.32.2.1 Limit States and Factors

In general, each component shall satisfy the following equation:

Where:

| = Total factored force effect | |

| = Force effect | |

| = Load modifier | |

| = Load factor | |

| = Resistance factor | |

| = Nominal resistance | |

| = Factored resistance |

Limit States

The following limit states shall be considered for bent design:

- STRENGTH – I

- STRENGTH – III

- STRENGTH – IV

- STRENGTH – V

- SERVICE – I

- FATIGUE

See LRFD Table 3.4.1-1 and LRFD 3.4.2 for Loads and Load Factors applied at each given limit state.

Resistance factors

- STRENGTH limit states, see LRFD 5.5.4.2

- For all other limit states, = 1.00

751.32.3 Details

751.32.3.1 Front Sheet

| Note: | The following are details and dimensions for the plan view of a typical pile cap bent on the front sheet of the bridge plans. Details and dimensions for an encased concrete pile cap bent are similar. |

| Details for unsymmetrical roadways shall require dimensions tying Centerline Lane to Centerline Structure. |

751.32.3.2 Typical Pile Cap Bent

|

|

| (*) 3" (Typ.) | |

| Part Elevation | Part Section |

|---|---|

| Use 2'-6" minimum or as determined by the superstructure requirements or the minimum support length required for seismic criteria (expansion joint bents only) (3" increments). | |

| = 2'-9" (Min.) for Wide Flange and Double-Tee Girders or, 3'-0" (Min.) for Prestressed Girders and Plate Girders. | |

| Check the clearance of the anchor bolt well to the top of pile. Increase the beam depth if needed. | |

| If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | |

| Use 3/4" drip groove where expansion device is located at bent. Continue to use 1-1/2" clear to reinforcing steel in bottom of beam. 3/4" drip groove shall be formed continuously around all piling at 3" from edge of beam. | |

| Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). |

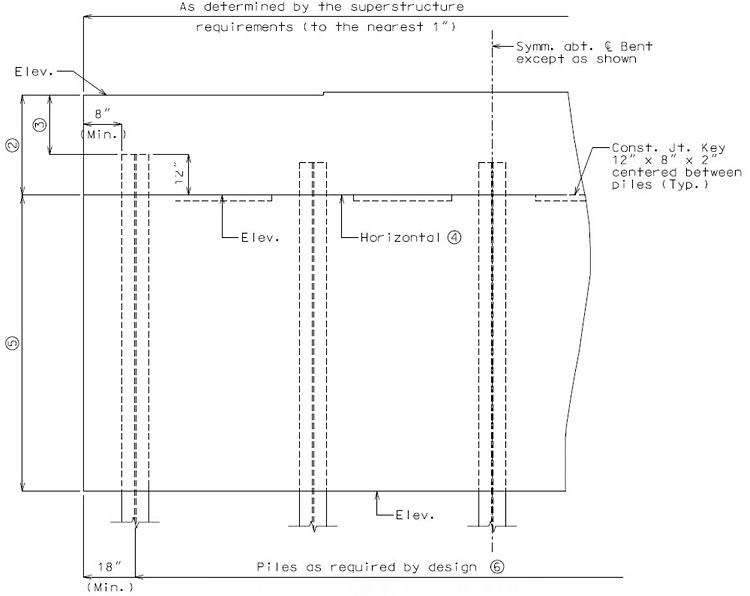

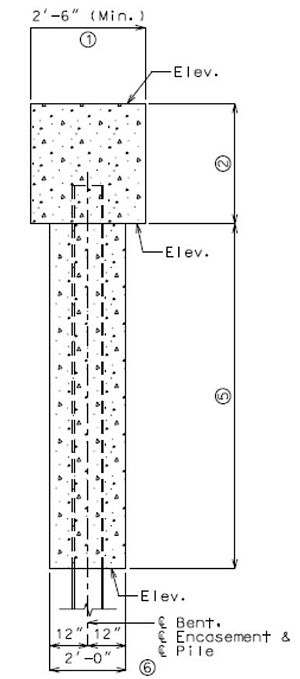

751.32.3.3 Encased Pile Cap Bent

Consideration shall be given to EPG 751.1.2.19 Substructure Type before using this type of structure.

|

| Part Elevation |

|---|

|

| Part Section |

| Use 2'-6" minimum or as determined by the superstructure requirements or the minimum support length required for seismic criteria (expansion joint bents only) (3" increments). | |

| = 2'-9" (Min.) for Wide Flange and Double-Tee Girders or, 3'-0" (Min.) for Prestressed Girders and Plate Girders. | |

| Check the clearance of the anchor bolt well to the top of pile. Increase the beam depth if needed. | |

| If the depth at the end of the beam, due to the steps, exceeds 4'-6", the beam bottom should be stepped or sloped. | |

| Height by design. Embed encasement 2 ft. (min.) below the top of the lowest finished groundline elevation, unless a greater embedment is required for bridge design. | |

| Minimum of 3 piles at 10'-0" cts., maximum spacing (1" increments). |

751.32.4 Reinforcement

751.32.4.1 Typical Pile Cap Bent

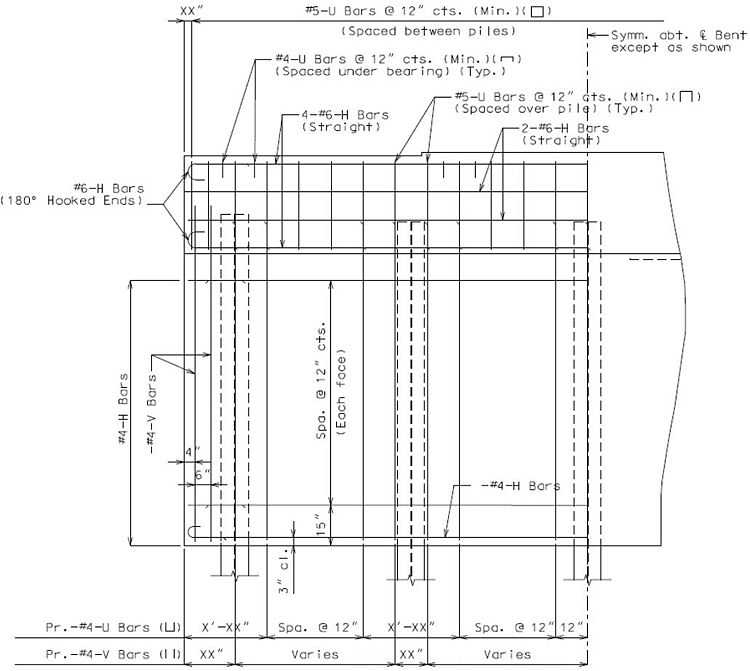

|

|

| Part Elevation | Section Thru Beam |

|---|---|

|

|

| Part Plan | |

|

|

| * #4 Bars ( | |

| Reinforcement Under Bearings | |

|---|---|

| |

| Transverse Beam Steps - Over 3" or Steps Accumulating Over 3" | |

| |

| Part Plan | |

|---|---|

| |

| Over 3" thru 12" | Over 12" |

| Longitudinal Beam Steps | |

751.32.4.2 Encased Pile Cap Bent

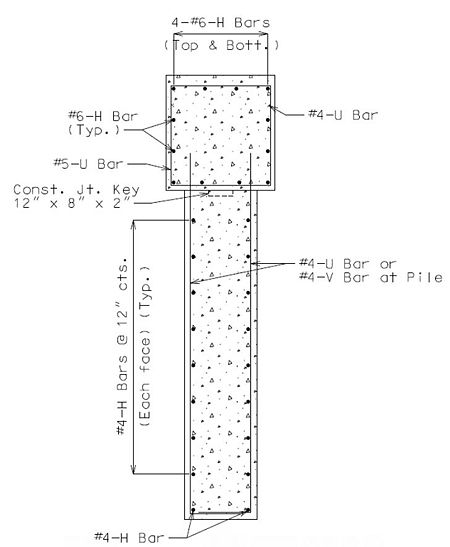

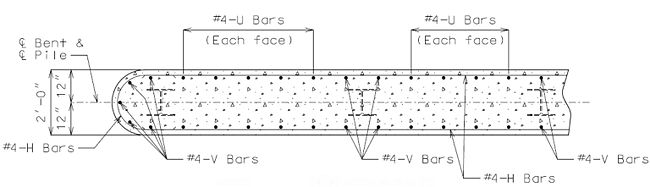

Supplemental details for encased pile cap bents are provided.

|

| Part Elevation |

|

| Part Section |

|

| Part Plan |