106.3.2.88 TM-88 Bond Strength Test for Tack Coat

Scope. This test method determines the bond strength of an applied tack coat material from a metal substrate. For new product approval, the testing apparatus, substrate, and the use of other alternate test methods are acceptable.

Equipment. The apparatus for this test (Fig. 106.3.2.88.1) consists of a unit suitable for evaluating pull-off strength (also referred to as adhesion) of a coating system from a metal substrate. The unit needs to:

- Have a range of 0 to 1000 psi,

- Have a resolution of at least 1 psi, and

- Have an accuracy of at least +/- 6.4 psi or better while performing a pull off test.

The testing unit may be stationary or portable and conform to ASTM D4541.

The metal substrate surface used for testing is a KTA 1/8” x 3” x 6” blasted cleaned 2 mil profile.

Adhesion testing dollies are used to apply the tack coat material and bond to the metal substrate.

Calibration. The apparatus for this test shall be calibrated based on manufactures recommendations and shall be supplied with a Certificate of Calibration. The calibration shall be done on an annual basis from the date of calibration.

Procedure. Thoroughly clean the dollies and bonding substrate surfaces that will be used for testing. The bonding substrate will need to be labeled to ensure that lot to lot testing is traceable. At least three test specimens shall be prepared to represent a tack coat product.

The tack coat material to be tested should be properly heated and mixed in accordance with the manufacturer’s recommendations. Upon proper mixing of the material apply enough material to the bottom of the dolly so that the bottom is completely covered and firmly press the dolly to the labeled metal substrates. The bottom of the dolly should be suitably covered, but not so much that the material rolls and bonds to the sides of the dolly.

The dolly material and bonding apparatus should now be left to cure for a minimum of 7 days at room temperature.

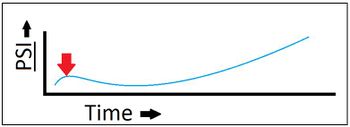

Once the 7-day curing period is complete, proceed with the manufacture's recommendations for turning on and operating the pull-off device. Set the pull off device to the lowest selectable pull rate. MoDOT uses 30 psi/second when doing this testing. Select the correct dolly size being utilized for the test. Complete the pull-off test and record the highest PSI observed during the start apparatus pull-off procedure.

Caution: if an asphalt binder is being used, the point of failure will not be recognized as there is still tension from the binder. Be aware that the highest PSI observed is at the start of the test as indicated by the red arrow in Fig. 106.3.2.88.2.

Calculation. Observe and record the highest pull off strength reported in PSI for the test specimens.

Average the ultimate strength values from each test.

The tack coat product producing an Average Ultimate Pull-Off Strength greater than 75 psi shall be an acceptable product.