902.23 Traffic Signal Phasing and Operation

902.23.1 Traffic Signal Operation

Support. Traffic signals can operate independently of any other traffic control signal ("isolated" operation) or their operation can be related to other traffic control signals ("coordinated" operation) forming a traffic control signal system.

Traffic control signals can be operated in pretimed, full-actuated, or semi-actuated control.

902.23.1.1 Pre-timed Control

Support. Pre-timed controllers direct traffic to stop or permit it to proceed according to a predetermined fixed cycle length and a division of the fixed cycle time between the various approaches to the intersection regardless of the actual vehicle demand. The sequence in which the signal indications are shown, and the time-relation of the signal to other signals are also pre-selected. Any or all of these features can be changed to accommodate specific needs.

In pre-timed operation, signal sequence is controlled by signal plans, which define the order of the signal intervals that are displayed. The amount of time given to each interval in a signal plan is determined by a timing plan. The time of the day at which specific timing and/or signal plan programs begin or end can be predetermined locally or remotely.

Pre-timed control can work well at intersections with tight spacing (i.e. diamond interchanges or central business district). However, traffic actuated controllers are preferred at most intersections: actuated controllers can run pre-timed but pre-timed controllers cannot run actuated.

902.23.1.2 Fully-actuated Control

Support. A fully actuated controller uses detection for all movements to determine the display and duration of vehicle and/or pedestrian movements at an intersection. The controller is able to skip those movements where no demand is present.

Fully actuated controllers have the flexibility of operating fully actuated, semi-actuated or pre-timed. The type of operation can also be changed by time of day.

Fully actuated controllers are available in two primary types, the NEMA, National Electrical Manufacturers Association, or the Type 170/2070 (Caltrans TEES, Caltrans Transportation Electrical Equipment Specifications). Both are keyboard entry and software driven machines. The NEMA controllers make up the bulk of the actuated controllers used in the state.

NEMA TS1 standards (refer to EPG 902.23.5.1 NEMA TS1) define the basic operating parameters of the controller as well as the inputs and outputs of the unit. This has led to the interchangeability of NEMA controllers between manufacturers. Most of the manufacturers have enhanced the operating software, adding many features that can be unique to that make and model. However, to be certified as a NEMA controller the basic operating functions are identical.

The NEMA TS2 standard (refer to EPG 902.23.5.1 NEMA TS2) expands the features of the TS1 standard, providing a higher level of standardization and interchangeability of equipment. TS2 also defines many of the features that have evolved in the current NEMA controller technology. Some TS2 functionality can be part of a TS1 cabinet.

The Type 170/2070 (refer to EPG 902.23.5.1 Type 170/2070) controller defines the hardware of the controller and allows the user to choose the software to run the controller. This has led to a great and almost total interchangeability of the controller and cabinet hardware but has left the user to evaluate and standardize on the software to run the intersection. Most of the features of the software are similar to the NEMA parameters. Although some hybrid versions of the 2070 have been created that can be used in NEMA cabinets, the true 170/2070 style controllers are designed for mounting in a 19” rack and meet Caltrans TEES (Caltrans Transportation Electrical Equipment Specifications).

All fully actuated controllers are able to respond to the traffic at the intersection. Minimum green times for called phases as well as extensions, when there continues to be traffic present, are programmable. There are also maximum green times, when a phase must be terminated to serve other calls, as well as yellow change and red clearance intervals that are programmable. There are other features available on a per phase basis such as pedestrian movements, added initial, maximum initial, minimum gap, time to reduce, time before reduction, minimum and maximum recalls. These features allow the fully actuated controller to serve the traffic in the most efficient manner.

The phases in an actuated controller can be assigned or grouped in many ways to provide unique operations that best serve the intersection's needs. The most common is the dual ring eight-phase configuration. This arrangement allows for separate through and left turn phases for up to four approaches. The opposing left turns are typically on concurrently, either leading or lagging. Through the software, the phases can be repositioned to provide a lead-lag left operation if so desired. Examples of typically used configurations are found in Signal Phasing and Layout Examples.

Efficient actuated operation is dependent on the type and placement of the detectors. Poor detector placement can have a serious impact on the delay and capacity of an intersection. Different types of detection are discussed in EPG 902.5.7 and EPG 902.15.3. Typically, stop bar presence detection is used. A common presence detector is a 6 ft. x 30 ft. area. Mainline through detection can be supplemented with advanced detectors located a distance from the stop bar based on the speed of approaching traffic.

Full actuation and advance vehicle detection on high-speed approaches are typically used to reduce the frequency of vehicles in the “dilemma zone”. The dilemma zone is the area where the onset of the yellow change interval creates difficulty for the driver to decide whether to stop or proceed.

902.23.1.3 Semi-actuated Control

Support. Semi-actuated intersection control refers to intersections where a fully actuated controller is used but one or more phases are not actuated. Typically, the mainline through phases are not actuated and the side streets and the mainline lefts are actuated. Timing for the non-actuated phases can be accomplished by using recalls. The non-actuated phases will remain in green until there is a call from one of the other movements and the minimum green timer is expired. The actuated phases work the same as in fully actuated control. To avoid or minimize unnecessary delay at isolated intersections fully actuated control is preferable to semi-actuated control.

902.23.1.4 Comparison of Pre-timed and Actuated Control

Support. Each principal type of traffic signal control, pre-timed and actuated, posses certain advantages not afforded by the other. The following discussion is intended to bring out basic differences in the different types of control, as to their operating characteristics and suitability for various traffic requirements. It is to be remembered that each type of control is capable of being modified in various ways for improved efficiency and flexibility.

With basic pre-timed control, a consistent and regularly repeated sequence of signal indication is given to traffic. Pre-timed control is particularly adaptable to intersections where it is desired to coordinate signal operation with closely spaced intersections.

Actuated control differs basically from pre-timed control in that signal indications are not of fixed length, but are determined by and conform within certain limits to the changing traffic flow or to the background cycle, if coordinated. The length of the cycle and sequence of phases might or might not remain the same from cycle to cycle since phases will not be serviced unless there are detections from waiting vehicles or pedestrians.

902.23.1.5 Advantages of Pre-timed Control

Support. Advantages of pre-timed control include the following:

- Consistent starting time and duration of intervals can facilitate more precise coordination with adjacent traffic signals.

- Pre-timed control can permit the operation of two or more very closely spaced intersections to operate at maximum efficiency.

- Pre-timed control is not dependent on vehicle detectors. Thus, the maintenance needs can be reduced.

- Pre-timed control can be more acceptable than actuated control in areas where large and fairly consistent pedestrian volumes are present, and where confusion might occur with the operation of pedestrian push buttons.

902.23.1.6 Advantages of Actuated Control

Support. Advantages of actuated control include the following:

- Can provide maximum efficiency at intersections where fluctuations in traffic cannot be anticipated or programmed with pre-timed control.

- Can provide maximum efficiency at complex intersections where one or more movements are sporadic or subject to variation in volume.

- Can provide the advantages of continuous signal control even in periods of light traffic without causing unnecessary delay to traffic on the major street.

- Can be used at locations where traffic signal control is warranted for only brief periods during the day.

902.23.2 Signal Phasing

Support. The phasing of a signal determines the order that movements are serviced. A study of traffic movements at the intersection is made to determine permitted and controlled movements. From this, the number and sequence of traffic phases is determined, which in turn determines the interval or color sequence and types of signal indications to be used. In general, the most efficient operation is obtained with the fewest possible phases; however, each signal installation is designed to provide safe and efficient control of conflicting traffic movements.

Guidance. The following articles provide guidelines for selecting phasing. Several examples are also shown in Signal Phasing and Layout Examples.

The typical phase arrangement at most intersections is with eight phases grouped into two sets of movements, or "rings". NEMA designates the assignments as follows:

A general form for actuated controller sequencing of an intersection is available. However, districts might have their own forms that are specific to the controller or software that is used at the intersection.

Phase assignment should be kept uniform in accordance with this ring structure whenever possible. Mainline left turns should be assigned to phases 1 and 5, with mainline through movements assigned to phases 2 and 6. Side street left turns should be assigned to phases 3 and 7, with through movements assigned to phases 4 and 8. Other phase numbering schemes can be used, but consistency should be maintained throughout the district.

As shown above, mainline leading left indications are displayed first. Phases on opposite sides of the "barrier" cannot operate together (such as phases 2 and 4). Phases on the same side of the barrier in one ring can run concurrently with phases in the other ring (e.g. phase 3 can be on at the same time as phase 8). Only one phase per ring can be on at any given time. (For example, if phase 2 is on, then no other phases in ring 1, such as phases 1, 3, or 4 can be on at the same time.)

902.23.3 Control Features for Non-coordinated Signals

Support. Control features for non-coordinated signals include:

- 1. Isolated Operation. Actuated operation can effectively minimize traffic delays at locations where coordination is not a consideration.

- 2. Traffic Density Timing. The traffic density timing feature provides for the initial green interval and/or the allowable traffic gap that ends the green interval, to be automatically adjusted according to traffic flow variations.

- The added initial setting increases the minimum green interval according to the number of vehicle actuations received during the preceding red interval (some controllers use both actuations received during the yellow and red intervals). This setting is intended for use where the shortest practical minimum green interval is not adequate for the traffic that can be stored between the advance detectors and the stop bar. The initial part of the green interval (minimum initial), remains short when few cars have arrived during the red interval, but it increases (added initial) a fixed amount per actuation during the red interval up to the maximum initial. At intersections with advance detection only (no stop bar detection), vehicles need more time to enter the intersection before they lose the right of way.

- Gap reduction which allows the passage time to decrease as the speed of the flow increases is another setting commonly used at locations with advance detection.

- Features of density control are discussed in EPG 902.5.37.2.

- 3. Recall Operation. Each phase of a controller is equipped with a recall feature. With recall disabled, the phase responds only to its detectors. With recall enabled, the controller can place a call to service that phase without vehicles being detected. This is accomplished by the controller placing a single call back to the phase when the clearance interval is initiated.

- Recall comes in several variations and has different uses. Minimum recall is normally used on the mainline through phases. Minimum recall guarantees the timing of the minimum green for the phase selected with additional green available through actuations. Using this feature on the mainline through is advantageous since during periods of light activity the controller will rest with the main street through green indications on. Maximum recall guarantees the timing of the maximum green interval for the phase selected. This feature is normally used when the detection for a phase has been disabled due to failure or removal. In this instance, the phase will always be serviced for the maximum green interval programmed that is to be adjusted accordingly.

- Many actuated controllers also have a feature called “soft recall” that allows the selected phase to be serviced only if there are no other conflicting calls. This feature can be used on the main street during periods of light traffic. The advantage over minimum recall is the controller can skip servicing the main street, if no real calls exist, and move on to the next called phase. This can provide a quicker response during the periods of light traffic.

- For more information about Recall Phases refer to EPG 902.5.37.6.

902.23.4 Coordination

Support. Coordination can provide nearly uninterrupted travel, resulting in one of the greatest benefits to motorists. Coordination provides many benefits other than less delay: the reduction of stops, crashes, fuel consumption, emissions, and driver frustration makes coordination one of the best values for the dollars spent.

902.23.4.1 How Coordination Works

Support. The key to coordinating signals is a common cycle length among all signals within the limits of the system. However, using a fraction of the cycle length, such as a half-cycle, can be used in some cases in order to reduce side-street delay while still maintaining mainline coordination. The start of a certain phase at each intersection, called the coordinated phase (usually the mainline through), is synchronized to a system reference point. This system reference provides a signal to each controller once every cycle. The cycle length is the total time it takes for a signal to serve all phases. The amount of time it takes for the coordinated phase at an intersection to start after the system reference is called the offset. Different offsets along a series of coordinated signals will provide different starting times of the coordinated phases. By setting offsets based on the speed of traffic in a certain direction, stops can be greatly minimized by starting the mainline green at that point where traffic from a previous signal just reaches the next signal.

Another important factor in coordination is what cycle length to run. Because volumes of traffic fluctuate throughout the day, different cycle lengths and offsets can be run to more efficiently handle the changing demands of volume in the system. Higher cycle lengths are generally used in the morning and evening peak times. Peak lunch times can also necessitate an increased cycle length. Weekend traffic can also justify cycle times that differ from weekday timing. Off-peak times use shorter cycle lengths. In a coordinated system, the time of day that each cycle length begins and ends must be the same for every controller for progression to work.

902.23.4.2 Planning a Coordinated System

902.23.4.2.1 Determine System Limits

Guidance.

Identification of how many signals to coordinate is the first step in building a signal system. Generally, knowledge of the arterial flow is a good start. Arterial streets where you can expect a group of vehicles to travel from one signal to another without a significant loss of vehicles turning off to another arterial or development can give reasonable limits.

The upper limit on spacing for coordinated signals has been assumed to be 1/2 mile. However, if the flow of vehicles can be maintained at a greater distance, then there is likely no reason to disregard additional signals in the system. Computer software can be used to establish the limits of a coordinated system. The "coupling index (CI)" formula can also be used if computer software is not available:

- CI = V / L

where:

- CI = Coupling Index

- V = 2-way volume on the link in vehicles per hour

- L = Length of link in ft.

The link is bounded by two signalized intersections. The units of the CI are meaningless.

For planning purposes, a CI equal to or greater than 0.3 during any hour indicates the possibility of including the signals within the system. For analysis of existing systems, a CI equal to or greater than 0.5 indicates the signals is to be coordinated during the hour analyzed, if they can be operated on equal cycle lengths. The CI formula provides a very simplistic method of determining the system limits.

The final factor in determining coordination limits is engineering judgment. Factors to consider for including a signal within a coordinated system are whether the intersection is over-saturated, already part of a system for the intersecting arterial or can be serviced with the system's cycle length.

All newly constructed signals should be reviewed for coordination and implemented if needed. Non-coordinated signals should be reviewed periodically to determine if coordination is to be provided.

902.23.4.2.2 Determine Timing Plans to Use

Guidance. The purpose of different timing plans is to match the traffic conditions in order to provide the best cycle lengths and split times. In most systems, the basic timing plans used during a week are:

- 1. Off-Peak

- 2. AM Peak

- 3. PM Peak

- 4. Late-Night Operation

Off-Peak operation generally uses lower cycle lengths than AM and PM peaks. Late-night operation can be free control or a short cycle length to minimize delays for the side street when signal coordination control is desired.

In addition, the traffic conditions along a system might not be adequately handled by only one off-peak plan. Mid-day and weekend patterns can greatly differ from off-peak patterns and could require separate plans. Even AM and PM peaks might require more than one plan if volumes and distribution greatly vary during those times.

Ideally, a 24-hour count of each intersection is to be obtained for at least a five-day period that includes a weekend but not a major holiday. This provides typical weekday and weekend traffic conditions. If every intersection cannot be counted, the major intersections are to be counted in this manner. From these counts, the times when traffic characteristics change in amount and/or directional distribution are to be charted.

In order to change from one timing plan to another, a transition period occurs which disrupts the coordination flow. Therefore, the start and end times of each plan should occur well before and after the worst hour during which the timing plan runs. If the transition occurs during times of peak flow, then any benefits provided by the additional plan can be lost by the disruption in coordination. If the transition cannot be made without disrupting the coordinated flow, then one plan should be used for a longer period in order to keep traffic moving. The timing plan chosen might not provide ideal conditions throughout the entire time it is in effect but should be set up to handle the worst hour of traffic during that time.

In addition to regular time-of-week timing plans, yearly conditions might require other timing plans. Arterials servicing seasonal tourist locations, large shopping centers and large schools will likely require the capability of timing plans that satisfy those seasonal conditions. For the best timing results, counts should be done that will take these conditions into account.

902.23.4.2.3 Determine Cycle Lengths for Timing Plans

Guidance. In most coordinated systems, the cycle length requirements differ from intersection to intersection for a timing plan. In order to run a coordinated system, a common cycle length will have to be chosen. Typically, computer software is used to determine appropriate cycle lengths. However, if computer software is unavailable the following procedures will provide a rough, but effective, cycle length to apply to an arterial.

902.23.4.2.3.1 Determine Minimum Cycle Lengths

Standard. The minimum cycle length in each system shall be determined by, the critical intersection, the intersection with the highest volume to capacity ratio.

Guidance. The critical intersection will likely have side street volumes that demand a significant amount of green time. In order to achieve any benefits of coordination, the proper amount of green time will need to be allotted to both the through traffic and the side street traffic. Two methods for determining minimum cycle length are:

(A) Critical Lane Volumes

| Sum of Critical Lane Volumes | Number of Phases | ||

|---|---|---|---|

| 2 | 3-4 | 5-8 | |

| 800 | 30 | 45 | 60 |

| 900 | 35 | 55 | 70 |

| 1000 | 40 | 60 | 80 |

| 1100 | 45 | 70 | 90 |

| 1200 | 55 | 85 | 110 |

| 1300 | 70 | 105 | 120 |

| 1400 | 90 | 120 | * |

| 1500 | 120 | * | * |

| * Intersection might be over capacity. Maximum recommended cycle is 120 seconds. | |||

The table above presents a way of determining minimum cycle length based on the sum of critical lane volumes and number of phases at the intersection.

(B) Highway Capacity Manual (HCM)

Appendix II for the "Signalized Intersections" chapter in the HCM presents a more detailed method of determining minimum cycle length. It is recommended to use the "Pre-timed Signals" procedure in the "Allocation of Green Time" section regardless of the type of control used, since a free-operating, fully-actuated signal will have to run nearly pre-timed operation in a coordinated system.

902.23.4.2.3.2 Final Determination of Cycle Length

Guidance. The determination of the minimum cycle length at the critical intersection should provide a starting point as to a practical cycle length for the system, but it should not be interpreted as an absolute value. Slight variations up or down might be required to best meet the demands of each intersection. Most arterial optimization software will require the user to input a lower and upper range for proper performance. If optimization software is not being used, the cycle length that provides the best service for the critical intersection should be used as the system's cycle length for that timing plan.

902.23.4.2.4 Determine Phase Times and Sequence for Each Intersection

Guidance. Computer software determines phase times and sequence when determining the cycle length. When calculating by hand, green times and sequences for each intersection should be determined after a cycle length has been determined. Since the purpose of coordination is to favor the progression of the coordinated phase, every effort is to be made to maximize the amount of green time and provide the best sequence to that phase.

902.23.4.2.4.1 Phase Times

Guidance. In order to run a pre-determined cycle length, actuated phases must be terminated, or forced off, after a certain amount of time regardless of the presence of vehicles. Actuated phases can still gap-out or be skipped if no calls are present but cannot extend past its force-off time for that timing plan. Non-actuated phases must extend to their entire force-off time. This force-off time per phase usually includes the green time and change period times.

If optimization software is being used, the program will generally give a force-off distribution for each intersection in the system. For non-computer planning, there are several methods to determine phase times. As with the cycle length determination, the HCM Appendix II in the "Signalized Intersections" chapter provides a basic procedure to allocate green time.

902.23.4.2.4.2 Phase Sequence

Guidance. When more than two phases are used, the sequence in which the indications are displayed must be determined for each timing plan. The usual choice is when to display a protected left turn in relation to the mainline green: at the start (lead) or the end (lag). The use of lead-lag for protected left turns on the mainline can greatly affect the progression. (See EPG 902.5.27.1 Leading and Lagging Left-Turns.)

If optimization software is being used, the program will generally give a mainline sequence at each intersection that maximizes the green band. Side street sequencing is usually left up to the user. There might be some timing plans where the side street sequence becomes a factor in coordination. A heavy left turn onto the mainline might call for a sequence that puts the side street left turn indications at a point in the cycle that allows for the group to clear a downstream intersection.

902.23.4.2.5 Determine Offsets and Transition in Each Timing Plan

Guidance. Once the cycle length, phase timings, and sequence have been determined, it is necessary to determine when to begin the coordinated phase in relation to the master cycle offset reference. The master cycle offset reference is a defined point during a 24-hour period to run the background cycle. In most cases, midnight is used as the master cycle reference point. The offset for each intersection will, if properly set, provide for progressed flow in the desired direction.

Option. Different offsets may be used for each timing plan at each intersection.

Guidance. The most common way to represent the flow of traffic on an arterial is the use of a time-space diagram. This type of graphical representation uses an x-y axis plot of red and green time, phase sequences, cycle lengths, and intersection spacing to display how well a platoon of vehicles moves from one end of the arterial to the other. The x-axis is a scale of the intersections by feet, and the y-axis represents the time scale in seconds (the x- and y-axis might be switched depending on the program used to create it.). Multiple cycles are laid out on the y-axis, with solid lines representing mainline red time. A green band represents the flow of vehicles whose slope represents the speed of the platoon along the artery. An example is shown below.

It will be assumed the user has a computer with a time-space diagram program available. Hand-drawn time-space diagrams are cumbersome, difficult to lay out, and nearly impossible to modify when changes are needed on the street. All further discussion on time-space diagrams will be based on the computer applications.

902.23.4.2.5.1 Offset Determination

Guidance. Determination of the offset using computer software can be accomplished by the following:

- (1) Enter basic information into the software program

- a. Distances between intersections, in feet. Measured from the center of each intersection.

- b. Phase times and sequence for each intersection.

- c. Speed of platoon between each intersection. For some arterials, it might be possible to maintain the same speed from end to end, but real conditions usually make this impractical to assume. Conditions such as closely spaced intersections, steep grades, and areas of heavy traffic will likely degrade free-flow speeds. Initially, the 85th percentile speeds, if known, can be used.

- d. Local controller's offset reference point. This is the point in the local cycle that the offset is referenced to and is the starting point of the local cycle (cycle zero). This point is typically at the beginning or end of the coordinated movements, usually the mainline throughs. Movements which are to be favored under coordination are designated as coordinated phases and the offset reference will be related to these movements. Many controllers offer options for the location of the offset reference.

- One or both of the coordinated phases typically start at local cycle point zero. If only one coordinated phase begins at local cycle zero with the other coordinated phase starting later in the cycle, this is referred to as "start of first coordinated green". If a second coordinated phase begins at local cycle zero after the start of the first coordinated phase, this setup is called "start of last coordinated green". If both coordinated phases begin together at cycle zero, either reference can be used. Additional options for offset reference are available in many controllers, see the manual of your specific controller for more options.

- e. Initial offset time, if available. If previous analysis used arterial optimization software to arrive at the cycle length and phase times, it likely provided an offset based on the desired direction of progression. This provides a good starting point but will likely need to be adjusted to match field conditions. If hand-calculation methods were used, the initial offset can be entered as zero and adjusted within the time-space diagram program.

- (2) Fine-Tune the Green Band

- After the basic information is entered, the user can open the time-space diagram to view the initial conditions entered. If all the information was accurately entered, this view will show what the user can expect to see on the street under the given conditions. The display will show, beginning at either end, the start and end of the green time projected in the direction of travel by straight lines. The slope of the lines is a function of the travel speed of the platoon. The area between these two lines is referred to as the green band. The bottom line of the green band represents the first car leaving the first intersection, with the top line the last car to clear before the indications turn red for mainline.

- Ideally, the goal is to keep this green band unbroken from one end of the arterial to the other for the direction the user wants to favor during that timing plan. However, in some cases, it might be more efficient to break the green band if a larger green band can be obtained following the break. For instance, a 30-second green band would probably be more efficient than a 10-second green band through the system. It is not uncommon that obtaining a continuous green band is impossible through the entire system particularly in large systems where two-direction progression is desired or where signal spacing is not optimal.

- During AM or PM peaks, it is common to favor one direction of flow. Off-peak plans usually require progression in both directions. In order to adjust green bands through the green time at an intersection, the user can usually move the intersection's phase time display up or down in relation to the y-axis directly on the screen and instantly see the effect on the green bands. This is graphically changing the offset time of the intersection. Once the user has adjusted all the intersections to show the best green bands, the final offset values is to be recorded for programming into the on-street controller. If all values have been entered correctly into the time-space diagram program, and then into the controllers, the user should see similar conditions on the street as shown on the computer screen.

902.23.4.2.5.2 Timing Plan Transition Determination

Support. When a controller changes timing plans, it needs a way to change to different phase times, offsets and possibly phase sequences as smoothly as possible in order to minimize the effect on progression. The two major transition methods are discussed here, since they are available on most every brand of controller, and either can be selected to best suit conditions.

- (1) Dwell Method. For this method, the controller will stop its cycle countdown and dwell at the local offset point in the cycle for either a predetermined amount of time, or until the master cycle zero point is reached, whichever comes first. Most controllers will dwell in the green time of the coordinated phases.

- The major advantage of this method is the transition can be completed in one cycle length if no set dwell time is programmed. Disadvantages to this method become more apparent as cycle lengths increase. Indefinite dwell times can cause up to a one-cycle delay before resuming normal operation. This becomes critical if the side street demand is high, or if the offset dwell point is on the side street and mainline has to stop more frequently during transition. If side street demand is low the use of the dwell method with a high or indefinite dwell time will allow for a quick transition with minimal impact.

- (2) Shortway Method (also commonly known as smooth transition). For this method, the cycle length is varied, it can be either higher or lower than its standard value until the proper offset is achieved. The amount of variance is usually no more or less than 20% of the desired cycle length. The major advantage of this method is it allows all other phases to be served with at least minimum green time, which is critical at intersections with many phases. The drawback to this method is that it might take several cycles to achieve the proper offset.

902.23.4.2.6 Adaptive Control

Support. Most traffic control systems today are based on time-of-day schedules where the traffic signal settings (cycle length, green times, offsets) are set by time-of-day based on historical data on traffic demand (e.g., am peak hour turning movement counts). However, some signal systems with two-way communication or central communication systems can escape the need to predict traffic flow and better account for variations such as weather, incidents, or major traffic generator events.

Traffic Responsive

Traffic responsive systems rely on user-defined timing plans consisting of cycle length, split times, and offsets, but instead of a scheduled time for enacting plans, a traffic responsive system will select a plan based on observed volumes and occupancies. There is no guarantee that a traffic responsive system will have a plan for the observed conditions, therefore plans must be developed to handle a needed situation in advance.

Since the response to the variation in volume and/or occupancy is a change in timing plans for these types of systems, care will be needed to ensure that timing plans enacted by the system are in operation for a significant minimum duration to prevent frequent timing plan transitions.

Traffic Adaptive

Traffic adaptive systems discard the need for timing plans based on cycle lengths, splits, and offsets. Instead, these systems generally respond to changes in traffic on a system-wide basis quite rapidly on a cycle-by-cycle basis for each intersection. Other than for system failure backup purposes, storage of traditional timing plans is not required – a traffic adaptive system continually computes the traffic control plan.

A truly traffic adaptive system will adjust the settings at traffic signals based on real-time data on traffic conditions, and can best respond to unexpected or unplanned events, such as incidents, special events, weather, etc., since they adapt the timings based on observed traffic data. Similarly, adaptive systems will improve performance over time-of-day plans when the traffic patterns have a high degree of variability. Also, adaptive systems will reduce the adverse effects of offset transition, preemption, and transit priority. However, extensive traffic detector instrumentation is required, and intersection controller equipment for adaptive systems is often more complex than for the other control categories.

| Adaptive Traffic Signals in Lee’s Summit |

| Summary |

| See also: Research Publications |

Support. Installation of adaptive traffic signal systems are recommended for further consideration for corridors where traffic demand changes quickly or in an unpredictable manner, where traditional timing plans are unable to accommodate coordination in two directions of travel, or where travel times are at least 50 percent higher than free flow travel times after signal timing plans have been optimized.

Traffic Adaptive “Light”

A hybrid of both the responsive and adaptive systems, adaptive “light” systems retain the need for traditional timing plans and fixed schedules for timing plan implementation but can change the split at each phase of the traffic signal cycle based on traffic measurements upstream of the intersection and demand on minor movements. Small changes in cycle time and offset are made during time periods ranging from each cycle to a few minutes. Benefits include the ability to adjust timing plans without the requirement to manually generate new plans – developed plans can be left in operation for a longer time and not require re-optimization. Another benefit is that the need for additional detection is far less for a “light” system than a fully adaptive system.

For additional information refer to FHWA’s Traffic Control Systems Handbook.

902.23.4.3 How to Interconnect for Coordination

Guidance. The method of coordination explained above is the same for every controller in a system. How that data is communicated between controllers and what information needs to be accessed remotely should be determined when desiring signal interconnectivity.

902.23.4.3.1 Determine Type of Interconnect

Guidance. The most basic interconnection system only requires an output from a master to the locals with a signal that controls:

- 1. Offset Break

- 2. Dial 2 On

- 3. Dial 3 On

- 4. Flash/Free Operation On

The basic setup offers no communication back from the locals to the master, and can be adequately handled with seven-conductor hardwire. If the need for coordination on the arterial is critical, and the flexibility of remote monitoring of all intersections and multiple timing plans are needed, a closed-loop system with fiber optic communication should be used.

If there is doubt as to how well coordination will work, or funding for a permanent type of interconnect is not available, then time base coordination (TBC) utilizing internal clocks of the controllers should be used. This allows for a very good demonstration of how coordination will affect the arterial. Also, TBC can be used on intersections outside the existing system limits to determine if interconnection needs to be extended.

Not every controller cabinet in use is set up for interconnection. If the signal has been operating outside of a coordinated system, an interconnect panel or device might be necessary to complete a connection to the controller. The final connection is through the controller’s Ethernet port. If the controller lacks this port, another type of controller that can accept Ethernet connectivity will be needed.

902.23.4.3.2 Types of Interconnect

902.23.4.3.2.1 Time Base Coordination (TBC)

Support. If coordination is between signals is desired but interconnection is not feasible, time base coordination can be used. The most important component in a TBC system is a highly accurate clock at each controller. Controllers have clocks built in and can respond to internal offset breaks and timing program changes. The advantage of TBC is its lower initial cost. Disadvantages are that the clocks drifting can cause significant disruptions in coordination and any program change needs to be made to each individual controller. The only way to maintain clock synchronization, with no additional equipment, is physical presence to re-synchronize the controllers on a regular basis.

The time clock in each controller acts as the synchronizer. All controllers in the system are set to the proper time within one second of each other. It is imperative that clocks be off no more than one second of any other clock in the system in order to ensure accurate coordination.

Because there is no master controller in a TBC system, the locals must act as their own masters and be responsible for producing an accurate offset break. Even if the clocks are synchronized in a system, the master cycle offset reference point must be the same for proper coordination.

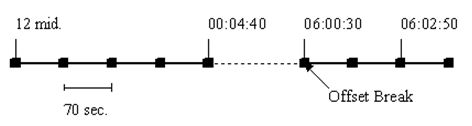

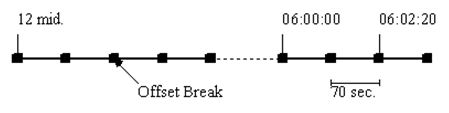

The following diagram shows how critical common offset reference can be to a TBC system:

- Example: A TBC system with two controllers running a 70 second cycle starting at 6 a.m.

- Controller 1 - Sync Reference: Midnight

At 6 a.m., this controller will look back to midnight and calculate when to time an offset break by starting the first 70-second cycle at midnight.

Controller 2 - Sync Reference: Start of Timing Plan

At 6 a.m., this controller will begin to time offset breaks every 70 seconds.

Due to the use of two different references, Controller 1's offset break is 30 seconds after Controller 2's. Therefore, if different offset references are used the coordination between the signals will be lost.

Because a TBC system does not have a master controller to give each local a signal as to what timing plan to run, each local is responsible for changing timing plans. The timing plans can be designated by different numbers (i.e. Cycle 3/Split 1 or Timing Plan 06) if the cycle length is similar, but for consistency, it is advisable to keep the same designation in each controller for each timing plan.

The start of each timing plan is typically at the same time for each controller, especially if the offset reference is the start of the timing plan. If all controllers are operating at a midnight reference for offset breaks, then timing plans which begin at slightly staggered times could be used with a slight delay in the onset of proper coordination. If the offset reference is at the start of the timing plan, then slightly staggered start times will give different times that the offset breaks start, and ruin coordination.

902.23.4.3.2.2 Ethernet-Over-Copper Interconnect

Support. For basic Ethernet-over-copper coordination, the controllers do not need to be the same model. However, the controllers’ internal command language must be the same. Failure to respond accurately to the desired timing plan can ruin any coordination effort.

One controller is to be designated as the master controller and send the proper coordination signals to the locals. CAT 6 cable is run into each cabinet and connected either directly to the controller, or through an ethernet switch in order to synchronize time clocks, switch coordination plans, and more.

Small systems isolated from central communication can use peer-to-peer communication to synchronize time clocks, switch coordination plans and more. The interconnect method can be CAT 6 or fiber optic cable (commonly run underground in conduit and pull boxes), by radio link between signals, or any combination of these methods.

902.23.4.3.2.3 Fiber Optic Cable Interconnect

Support. Fiber optic cable is the preferred method for interconnecting both short and long runs between signals. The fiber optic cable is run into each cabinet and connected to an internal controller modem or an Ethernet switch, which translates the optical information into data the controller can recognize.

Fiber optic interconnect has several advantages over copper wire interconnect cables. Fiber does not transmit electrical energy from lightning which helps prevent lightning damage to control equipment. The signal demands on the fiber optic capacity is small enough that the cable run can be used in the future for other uses such as real-time video surveillance and connection to ITS systems.

The disadvantages of fiber are the need for higher technical expertise to install and maintain the cable and expensive special equipment.

902.23.4.3.2.4 Wireless Interconnect

Support. Wireless interconnect is an option when it is not practical, physically or financially, to run conduit and fiber optic cable between the controllers. Types of wireless interconnect may include cellular, which connects back to the central system, or radio, which connects point to point.

902.23.4.3.2.5 Mixed Interconnection

Support. Not every system needs to have the same type of interconnection between all controllers. In some locations where hardwire interconnect can be installed between controllers and other links have physical barriers which prevent conduit, wireless interconnect might be a viable option to complete the system. Any mix of hardwire, fiber and wireless can be used as long as the end protocol is the same.

902.23.4.4 Communication between Controllers

Support. Regardless of the type of communication between controllers, several basic items will be received by all intersections to operate a system properly. More advanced systems can be remotely accessed and monitored from a central computer system.

902.23.4.4.1 Master and Local Controllers

Support. In all systems, one controller or central computer system is responsible for keeping an accurate clock running, generating an offset reference and storing timing plan start and stop times. A controller in this capacity is referred to as the master controller of the system, and it can also act as the controller for a specific intersection. It transmits this information to the other controllers in the system which are called local controllers. The locals can have similar information stored in them as the master (e.g. synchronized time clock, timing plan start and stop times), but use this information only as a backup in case of failure in communication with the master. The local controllers are responsible for having each timing plan the master might call for loaded into their memory. The timing plan in the local controllers must include phase times for each interval that add up to the proper cycle length called for from the master, and the offset value unique to that intersection. Offsets and what timing plans to run are transmitted from the master and are recognized by the locals. Every local must interpret the master signal as the same command. Failure by one local to recognize this signal will disrupt coordination in the system.

902.23.4.4.2 Closed Loop

Support. Closed loop systems allow for remote access to the local controllers through the master controller in order to monitor, change or upload information at each intersection. Any information that can be programmed or stored at a local controller can be remotely accessed in a closed loop system. Remote access can be through a computer connected to the master or front panel access to the locals at the master controller.

902.23.4.4.3 Central Control Systems

Support. In centralized systems, a central computer makes control decisions and directs the actions of individual controllers. Each intersection requires only a standard controller and communication link to the central computer.

Central systems have the following characteristics:

- They depend on reliable communications networks. Since real-time control commands are transmitted from the central computer to the local intersections, any interruption in the communications network forces the local controllers to operate without that real-time control and revert to its backup plan via time-based control. If an interruption in communication occurs while in coordination a transition is required from central control to local control. During this transition, signal coordination is usually lost for a short period of time. For this reason, communications networks for centralized systems usually include some form of reliable communications, such as fiber optics.

- They depend on reliable central computers. Without the central computers, centrally controlled systems cannot happen. When the central computer is down the system has the same problems as when the communications network is down, except that the problem affects all intersections, not just the few that are on that communications branch. Staff dedicated to healthy computer system operations is a must for reliable central control.

- They are expensive. Most of the cost in a central system is providing the communications networks – easily a much higher investment than the central system’s software.

- They provide excellent surveillance response time. The system’s communications network is reliable enough to allow mandatory real-time control communications. In most situations, this requirement ensures once-per-second return of surveillance information such as status of phases and detectors, and controller alarms requiring maintenance attention.

- They allow centralized control algorithms. This is the one area where centrally controlled systems have a distinct advantage over traditional “interconnect” systems – the ability to define a signal coordination plan by need instead of physical connection to each intersection. As long as a controller has some sort of communication link back to the central computer, the intersections so designated can run in coordination. Central control allows these system limits to vary by both time of day and on manual needs such as incident response for detour routes.

Many traffic adaptive systems require a central computer to calculate the optimization algorithm for the entire network. Only a centrally controlled system can provide this capability.

902.23.4.5 Diamond Interchanges

Support. Due to the close spacing of both ends of a standard or compressed diamond interchange it is extremely important to offer coordination between both ends of the interchange. This can be accomplished with pre-timed or actuated control.

This discussion primarily relates to standard diamond interchanges, however similar considerations can also be made for half diamond and other diamond interchange variations. If a signalized roadway (i.e. outer roadway) is very close to a ramp intersection, a different configuration might be required.

Option. Coordination between both ends may be accomplished by running a pre-timed operation during the critical peak times and actuated operation during the off-peak times. This option is to be evaluated carefully, as coordination during actuated operation may not be optimal.

Guidance. The merits of each setup should be evaluated for the best operation at each location. The following are recommended criteria for selecting the best setup. A cost comparison might also be helpful in deciding which setup to use.

Actuated Control with One Controller:

- Overall interchange operates below capacity.

- No more than two mainline or ramp left turn movements require critical coordination.

- There is sufficient left turn storage between the ramps.

Actuated Control with Two Controllers:

- Overall interchange operates below capacity during off-peak.

- None of the movements require critical coordination during off peak.

- There is sufficient spacing and left turn storage between ramps for non-coordinated operation during off-peak.

Pre-timed Control with Two Controllers:

- Overall interchange operates near or at capacity.

- Most or all of the mainline and ramp left turn movements require critical coordination.

- There is not sufficient left turn storage between the ramps.

Diamond Interchange Examples provides examples of phasing configurations for diamond interchanges.

902.23.5 Controller Assembly Components

902.23.5.1 Controller Unit

Support. The controller unit (CU) is a solid-state traffic actuated unit. The CU interfaces with a number of low voltage (logic level) input and output functions to control signal lamps, receive inputs from detectors, operate in coordinated systems, etc. Additional information on types of control is found in EPG 902.5.2 Traffic Signal Operation.

NEMA TS1

The NEMA TS1 is a common cabinet configuration for solid state controllers. The back panel for a TS1 cabinet configuration has terminals that are used to interface with the other devices in the cabinet, call certain features of the controller, as well as to display the indications on the street. Harnesses are provided to route the wiring from the controller to the rear of the back panel. By using jumpers on the front of the back panel, the inputs and outputs of the controller can be assigned. The physical makeup of the back panel is described in Sec 902.

NEMA TS2

The NEMA TS2 standard replaces much of the discrete cabinet wiring with high speed serial communications interfaces. In addition, the communications allow the CU, malfunction management unit (MMU), backpanel, and detector rack to exchange information on a regular basis, performing redundant checks on each other.

The TS2 Type 1 standard uses EIA-485 serial communications interfaces and Synchronous Data Link (SDLC) communication protocol to link the major cabinet components. The serial data is converted to analog inputs and outputs in the back panel and detector rack by a bus interface unit (BIU).

The back panel for a TS2 cabinet configuration is also used for the termination of controller inputs and outputs. Load switch drivers and other functions of the controller have terminals on the back panel that are used to interface with the other devices in the cabinet and to display the indications on the street. The back panel is linked to the CU through one or more BIUs. Load switch assignments and other back panel functions are configured through the controller software. Discrete wiring is still provided between the back panel and the MMU to monitor load switch outputs.

Type 170/2070

Cabinets for Type 170/2070 Controllers use a 19 in. rack assembly to secure equipment and follow Caltrans standards (California Department of Transportation). The controller unit and cabinet assemblies are attached to the racks. Cabinet assemblies consist of the power supply assembly, power distribution assembly (PDA), input file, and output file. The power supply and PDA provide power, circuit protection and surge suppression for cabinet equipment. The PDA houses the flasher and auto/flash switch. The input file houses card rack detectors, isolators and other input devices. The output file houses load switches, flash transfer relays and the monitor. Other auxiliary equipment can be rack mounted or mounted by other means. Terminations for wiring are made on the back of associated cabinet assemblies.

902.23.5.2 Conflict Monitor Unit / Malfunction Management Unit

Support. All solid-state controllers have a conflict monitor unit (CMU) or a malfunction management unit (MMU) to supervise the operation of the traffic signals. The primary purpose of this unit is to guarantee that conflicting signal indications are not displayed on the street at the same time. If such a conflict is detected, the unit will automatically put the intersection into a flashing condition. The intersection will remain in flash until the monitor unit is reset and the problem that caused the failure is corrected.

These monitors can also monitor the absence of signal indications on the street. The absence of a load on the output side of the load switch when that output is turned on will cause the monitor to put the intersection into a flashing condition. This occurs when all the bulbs of the same color on a particular phase are burned out or when a wiring failure causes loss of power to the indications.

Standard. For phases with only one signal head (i.e. a left turn phase with a single turn lane), load resistors shall be adequate for the output so that a single indication outage will not cause the intersection to go to flash.

Support. Each conflict monitor has a program card that is unique for that intersection. On the program card, jumpers are installed to tell the unit which movements, or channels, are considered compatible. Those positions not having jumpers are considered as conflicts and will trip the monitor.

The monitors also check the controller. If power is lost to the controller or if the internal 24-volt DC voltage of the controller is lost, the monitor will trip, and the intersection will go into flash. Some of the newer conflict monitors available exceed the minimum specifications set out by NEMA.

In NEMA TS2 cabinets, communications between the MMU and the CU allow the ability to monitor for fault conditions between the major cabinet components. Certain fault conditions will cause the intersection to go into flash. Some examples of these faults are the loss of serial communications, incompatibility between MMU program card and CU phase sequences and discrepancies between load switch outputs and CU phase outputs. In no case is a solid-state controller operated without a monitor unit.

902.23.5.3 Load Switches

Support. The operating voltages of the solid-state controller are 24 volts DC. This voltage must be converted to 120-volt AC in order to drive the signal indications. The load switch is a solid-state device that converts the 24-volt DC output from the controller to the 120-volt AC needed by the indications. Each load switch can handle three circuits. Normally, one switch is assigned for each phase and it handles the green, yellow and red outputs. A separate load switch is used to control pedestrian indications, if they are present at the intersection. Strategies used for flashing yellow arrow indications vary.

902.23.5.4 Auxiliary Interfaces

Support. Other auxiliary interfaces might also be needed in the controller cabinet. Examples of these include hardwire interconnect interfaces, closed loop system interfaces and preempt interfaces. These typically consist of a panel or unit that brings external inputs, outputs and communications into the CU.

902.23.5.5 Detector Interface

Support. The detector interface provides connections between the CU and the detection devices. In solid-state pre-timed and NEMA TS1 controllers, the connections are made through the back panel. In NEMA TS2 controllers, the detector inputs and outputs are linked to the CU through a BIU. In Type 170/2070 cabinets, the input file serves as the detector interface.

902.23.6 Detectors

Support. The basic goal of a detector is to provide a valid input to the controller unit of the need to provide service. There are many types of detectors currently in use and more are consistently being developed. Detector types include, but are not limited to, pedestrian push buttons, inductive loops, video detection, and radar detection.

There are two primary types of detection: pulse (or passage) and presence. In pulse detection the detector provides a short instantaneous call to the controller that demand is present and then the call is dropped. Presence detection registers that demand is present and will retain the call so long as there is demand.

A resource for information on additional detector types, alternate loop designs, and many other aspects of detectors is FHWA’s Traffic Detector Handbook (also available through ITE).

902.23.6.1 Induction Loop Detectors

Support. Induction loop detectors consist of wire that is placed in the pavement that senses the passage or presence of metal objects (i.e. vehicles). The detectors’ inductance is based on the number of turns of wire in the saw cuts in the pavement, and the current flowing through them. The passage or presence of a metal mass changes the inductance of the loop. The detector amplifier then measures this change in inductance and when the set thresholds are exceeded, detection is registered.

902.23.6.1.1 Loop Configuration

Support. The most common arrangement of the loop detector is the quadrapole. This layout, a rectangle with an additional cut down the middle, provides the greatest sensitivity of detecting small vehicles, motorcycles, and bicycles while reducing the occurrence of cross talk between loops in adjacent lanes and false calls from adjacent lanes. The typical quadrapole loop is 6 ft. wide by 30 ft. long located at the stop bar in each lane. Quadrapole detectors shorter than 30 ft. are sometimes used when field conditions don’t allow for full size loops.

Another widely used loop configuration is the 6 ft. x 6 ft. square loop. This loop, which is centered in the lane, is typically used for detection in advance of the signal. This layout is more susceptible to cross talk and false detections but with proper adjustments of the amplifier, good performance can be achieved. This loop configuration is also typically used for vehicle counting. A variation of this loop is a diamond shaped loop. By turning the square loop 45 degrees, the more sensitive corners can be centered on the lane.

There are additional loop layouts, such as the skewed loop, round loops and several other variations available. See Comparison of Induction Loop Detector Designs and Standard Plan 902.50 for more information.

902.23.6.1.2 Induction Loop Detector Amplifiers

Support. Induction loop detector amplifiers are installed in the controller cabinet and are available in shelf-mount and rack-mount configurations. The shelf-mount units are self-contained and are connected to the controller backpanel through a wiring harness. Rack-mount units are installed in a card rack with separate power supplies. Type 170/2070 and NEMA TS2 controllers use only rack-mount detectors. The TS2 detectors have additional diagnostics that are linked to the CU through the serial communications.

902.23.6.2 Probes

Support. Probes are point detectors that are installed in the pavement. There are two types: micro-loops and wireless probes. They operate on a similar principal to a conventional loop detector. Micro-loops have a continuous lead in to the controller cabinet. Wireless probes sometimes require repeaters.

Probes are typically used at locations where the pavement is not able to support the cutting of a loop or right of way is limited. The principal drawback is a smaller detection zone, but through the use of several probes in an array, probes can closely simulate a long detector.

902.23.6.3 Microwave (Radar)

Support. Consisting of an emitter/sensor mounted either above or adjacent to the pavement, microwave detectors measure the Doppler shift in the microwave frequency and detect the passage of a vehicle. Simple microwave units are designed to place a call if an approaching vehicle is sensed for one lane or the entire approach. More advanced microwave detectors can define multiple zones of detection with one unit and can measure speeds. Microwave detectors are also directional; they can distinguish if a vehicle is approaching or leaving the detector.

A big advantage of microwave detectors is that they do not need to be installed in the pavement. This can allow for greater flexibility in installation as well as avoiding the problems associated with being in the pavement.

902.23.6.4 Video Detection

Support. Video detection consists of a video camera mounted above or adjacent to the pavement and a unit that processes the video signal to generate vehicle calls and other information. The processing unit uses software to draw zones of detection on the video output.

Video detection typically has a higher initial cost but offers the advantages of being completely out-of-pavement and allowing considerable flexibility in detector placement and configuration. Video detection can require one or several cameras to be effective and requires a rigid mounting location for the cameras. Higher mounting locations will provide more effective detection. One of the most common disadvantages of video detection is the potential for poor performance during inclement weather.

902.23.6.5 Closed Loop System Detectors

Support. The objective of system detectors is to gather data that the system master uses to make decisions on timing plan and offset patterns (see EPG 902.23.4 Coordination for more information). The data from these detectors can also be used as a monitoring tool for the system. The primary difference between system detectors and standard detectors is that system detectors do not have direct control over signal phase times. The master can use data from the system detectors to make system wide decisions based on parameters set by the user.