Category:172 Maintenance Facility Performance Expectations Environmental Compliance

For additional information or help, the Design Environmental contact may be called at (573) 526-4778.

172.1 Salt Management – Salt Kill

Citation: Sections 644.051.1 & 644.076.1, RSMo 10 CSR 20-6.015, Missouri Clean Water Law and Regulations

Performance Expectation

Remediate salt kills on and off MoDOT property.

Performance Measure

Identify evidence of dead or stressed vegetation on or off MoDOT property; includes remediated areas where evidence of a salt kill is currently visible. Develop and execute a plan to remove the contamination and reseed the affected area.

Acceptable Solutions

1. Prevent runoff of salt and notify adjacent landowner to offer corrective measures. Contact your district environmental specialist and risk management representative for assistance.

2. Remove soil and replace with clean soil and reseed.

3. Divert runoff from entering the neighbor’s property.

4. Keep all salt and salt mix under cover.

5. Clean up all salt outside and maintain an impervious pad in front of the storage area.

6. Contact the district environmental liaison for additional options.

|

|

|

|

172.2 Salt Ponds and Basins

Citation: Sections 644.051.1 & 644.076.1, RSMo 10 CSR 20-6.015, Missouri Clean Water Law and Regulations

Performance Expectation

Salt ponds are to be closed and where engineered collection basins are installed they are to be maintained.

Performance Measure

Remove salt pond and dispose of the water in an approved manner. Maintain engineered collection basins and use the water for brine.

Acceptable Solutions

1. Close salt ponds by hauling the water to a permitted publicly owned treatment works (POTW), dig out contaminated soil and dispose of in a permitted solid waste landfill and backfill / grade /seed the area.

2. Engineered salt collection basins have to be maintained by periodic cleaning and resealing.

Note: Salt water can be used to make salt brine if it consists of only water and salt.

172.3 Salt Piles

Citation: Sections 644.051.1 & 644.076.1, RSMo 10 CSR 20-6.015, Missouri Clean Water Law and Regulations

Performance Expectation

Storm water on maintenance lots shall be protected from salt contamination.

Performance Measure

All salt must be covered and stored to prevent contact with rain or rain runoff.

Acceptable Solutions

1. Salt will be under cover before any precipitation comes in contact with the material.

2. Any salt outside after a snow or ice event has to be cleaned up and returned to the covered area.

172.4 Salt Bays and Mixing Pads

Citation: Sections 644.051.1 & 644.076.1, RSMo 10 CSR 20-6.015, Missouri Clean Water Law and Regulations

Performance Expectation

Protect salt from contact with storm water

Performance Measure

Conduct visual inspection of the storage areas periodically to ensure the salt is kept out of the elements. Maintain the buildings and covers to prevent moisture from coming in contact with the salt.

Acceptable Solutions

1. Discontinue salt bays that do not protect the salt from the elements – construct fabric buildings, domes, tents or other approved buildings.

2. Salt bays still in use shall be maintained in good condition with tarp / door system to protect the material from contact with rainwater and keep salt back away from rain. All mixing pads must be impervious to allow easy cleanup after an event.

3. Re-contour surrounding terrain and direct storm water away from salt storage or relocate salt storage structures if storm water runoff cannot be directed away from structure.

172.5 Wash Water

Citation: Sections 644.051.1 & 644.076.1, RSMo 10 CSR 20-6.010, Missouri Clean Water Law and Regulations

Performance Expectation

Vehicle and equipment washing must be done where the water can be collected and properly treated prior to release to the environment or waters of the state.

Performance Measure

Wash equipment only where the resulting wash water can be contained or treated.

Acceptable Solutions

1. Drive vehicles/equipment to MoDOT lots with appropriate collection systems to wash them.

2. Allow rural facilities to wash vehicles/equipment at commercial truck washes.

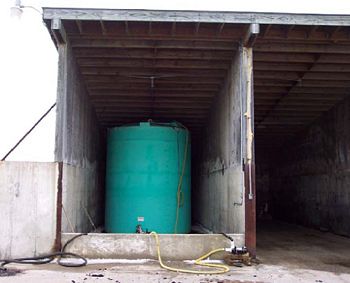

3. Covered wash bay with sewer connection or tank system.

4. Install an onsite treatment system. This would require a discharge permit.

5. Construct same for rural facilities and pipe waste water to a holding tank. Wastewater must be removed on a regular basis and transported to nearest public sanitary sewer system. Solids will need to be disposed of at a permitted sanitary landfill. One option could include recirculate the wash water for gross washing followed by clean power wash. All material must be collected.

6. Construct covered wash bay with an oil/water separator and connect to public sanitary sewer system where available and allow rural facilities to use approved MoDOT washing facilities or local commercial wash facilities.

7. Install a zero discharge recirculation system for washing trucks.

Note: Do not discharge to a sewer without notifying the public waste treatment facility.

|

|

172.6 Storm Water

Citation: Chapter 644 RSMo; 10 CSR 20-6.015, Missouri Clean Water Law - Permit and Water Quality Regulations (No Discharge Permit); 10 CSR 20-7.031(3) (Water Quality Standards)

Performance Expectation

Storm water from maintenance facilities needs to be controlled to prevent aggregate, silt and sediment from being washed off the property into ditches and waterways.

Performance Measure

Inspect all areas on the maintenance lot where storm water potentially leaves the facility and develop and implement a plan to control the runoff.

Acceptable Solutions

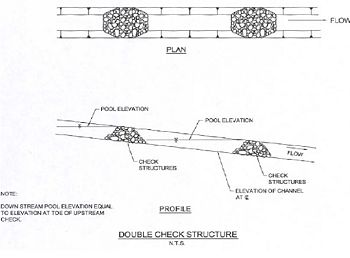

1. Evaluate problem and implement facility improvements to keep silt, rock, aggregate and other materials on the lot at locations where storm water flows off-site. For example: install an aggregate berm that allows storm water to flow through, but contain aggregate material from migrating offsite. If this is the chosen option, these structures must be constructed in such manner that they do not retain water, but will catch sediment and can be maintained. Use mixture of fines and course material that will slow down the storm water for material to settle.

2. Install grass buffers that are sufficient to catch material and filter storm water runoff. Install so they can be maintained.

|

|

|

|

172.7 Secondary Containment for Brine

Citation: Sections 644.051.1 and 644.076.1, RSMo; 10 CSR 20-6.010, Missouri Clean Water Law and Regulations (Construction and Operating Permit)

Performance Expectation

Keep all snow control chemicals (brine, beet juice (Geomelt) and calcium chloride) from entering waterways. Though not required by law, a release of the material to the environment would be regulated and could result in a major cleanup expense.

Performance Measure

Place all storage tanks, pumps and plumbing inside watertight secondary containment. Check tanks and pumps for integrity.

Acceptable Solutions

1. Berm of clay, concrete, synthetic liner or impervious material with drainpipe and closed lockable valve.

2. Locate snow control chemical tanks including pumps and plumbing inside existing buildings where available and provide secondary containment.

3. Construct secondary containment structure for snow control chemical tanks including pumps and plumbing.

|

|

172.8 Hazardous Waste Disposal

Citation: 40 CFR Subchapter I, Federal Hazardous Waste Management Law; Sections 260.350 to 260.430 RSMO; 10 CSR 25 Chapters 3-7, 11-12,16; Missouri Hazardous Waste Management Law and Regulations

Performance Expectation

Ensure that all the materials are usable and do not become “waste”, which would create an environmental liability.

Performance Measure

Identify unusable materials and chemicals and contact your district environmental point person and environmental specialist for proper handling or disposal. Contact your district environmental specialist to assist with materials that cannot or will not be used at a MoDOT facility.

Acceptable Solutions

1. Control Inventory – order only one to two years worth of materials.

2. All containers storing unknown material should be sampled and characterized for proper handling and disposal by an environmental specialist.

3. If usable material (chemicals, paints, etc.) cannot be used at a lot, it should be shared with or given to another MoDOT facility that can utilize the materials.

4. All known or unknown materials not currently used (chemicals, paints, etc.), which cannot be used by other MoDOT facilities or that are out-of-date and no longer usable, must be disposed of at a permitted hazardous waste disposal facility (contact your district environmental specialist for assistance).

5. Do not move hazardous waste to another location (contact your district environmental specialist for assistance).

Note: Do not dump any product on the lot to dispose of the material. Refer to the MoDOT “Environmental Standard Operating Procedures for Sale of MoDOT Property” for guidance when selling excess materials or chemicals.

172.9 Drains

Citation: Sections 644.051.1 and 644.076.1, RSMo; 10 CSR 20-6.010 Missouri Clean Water Law and Regulations (Construction and Operating Permit)

Performance Expectation

Facilities with floor drains in the maintenance bays that are not plumbed to a public sewage system shall be closed to prevent water from entering the environment or corrected with a connection to an approved alternative.

Performance Measure

All systems not connected to an approved holding tank or public sewage system must be closed.

Acceptable Solutions

1. Connect all floor drains to an oil / water separator and public sanitary sewer system where possible. For facilities where floor drains are not connected to a public sanitary sewer system, the facility must plug, seal or otherwise prevent discharge from the floor drains.

2. Connect floor drains to a holding tank and have contents removed by waste hauler.

3. An oil/water separator can be used as a holding tank or prior to a holding tank.

|

|

172.10 Spill Prevention Control Countermeasure (SPCC)

Citation: 40 CFR 110 (defines facility), 40 CFR 112 (SPCC plan requirements) U.S. Environmental Protection Agency (EPA) Regulations

Performance Expectation

All maintenance lots with 1,320 gallons of petroleum, animal or vegetable oil products storage capacity are required to have and maintain an SPCC plan at their facility.

Performance Measure

Bring all plans into compliance by updating the plan to fit the facility. Every five years a professional engineer reviews, signs, and stamps the plans. Next plan update expected spring 2010.

Possible Solutions

1. (Fencing on hold pending automated fuel system decision and new SPCC guidance.) Install adequate fence and locking gate to secure maintenance lots. In some areas the site may only require barbed wire fence or guard cable to restrict vehicular traffic.

2. All petroleum and oil-based material containers 55 gallons or greater must have secondary containment.

3. Containers with double walls need containment for the pumps and plumbing for the contents of the container.

4. Maintain annual personnel training and monthly facility inspections.

5. Maintain equipment, tanks and containment to prevent spills.

|

|

|

|

|

172.11 SPCC and Various Statewide Issues

Citation: 40 CFR 110 (defines facility), 40 CFR 112 (SPCC plan requirements) U.S. Environmental Protection Agency (EPA) Regulations, Solid Waste Management Law in Sections 260.200 through 260.345 RSMo

Performance Expectation

Keep all materials organized and the facility clean of debris.

Performance Measure

Perform routine inspections to identify problem areas. Maintain training to keep in compliance with SPCC regulations

Requirements

1. Maintain the spill kits and store them near fuel islands for easy access during on-site spill events. (Note: There is a statewide general services contact to replace used materials.)

2. MoDOT is using environmental equivalents for petroleum storage tanks to meet storage tank monitoring requirements to comply with SPCC regulations. Keep the tanks painted.

3. Asphalt tank marking/labeling/locking is needed to comply with SPCC regulations.

4. When any petroleum tank is taken out of service, it should be label “Closed”, with date of closure, and valves and ports are to be closed and locked. See picture in SPCC section.

5. Asphalt hoses need collection or containment rather than being allowed to drain onto the ground.

6. Facilities with oil/water separators need to have these scheduled for regular clean out.

7. Septic tanks need to have scheduled clean outs. Best management practice avoids costly repairs.

8. Parts washing solvent should be converted to the Zep® solvent or other non-hazardous equivalent.

|

|

172.12 SPCC and Portable Tank Storage

Citation: 40 CFR 110 (defines facility), 40 CFR 112 (SPCC plan requirements) U.S. Environmental Protection Agency (EPA) Regulations

Performance Expectation

When a portable tank is in storage for future use it must be in secondary containment.

Performance Measure

Perform routine inspections of portable tanks to identify problem areas. Maintain training to keep in compliance with SPCC regulations.

Requirements

1. Containment must be large enough to hold the volume of the tank if stored inside and large enough to hold the volume plus a 25-year rain event if stored outside. Even if the tank is empty it must be in containment.

2. Containment must be made of material compatible with the tank contents and impervious to leakage in the event of a leak until it can be cleaned up.

3. The tank must be kept painted and visually inspected for rust and damage.

4. If a portable tank is taken out of service, it should be label “Closed”, with date of closure, pumps removed, and valves and ports are to be closed and locked.

|

|