147.3 Job Order Contracting (JOC)

Contents

- 1 147.3.1 Fixed Unit Price List and Non-Fixed Cost Items

- 2 147.3.2 Adjustment Factor

- 3 147.3.3 JOC Development: Job Special Provisions and Plan Sheets

- 4 147.3.4 Issuing Job Orders

- 5 147.3.5 Term Extension of Job Order Contracts

- 6 147.3.6 Closing JOC Contracts

- 7 147.3.7 Budget Adjustments for JOC Contracts

- 8 147.3.8 Delayed JOC Projects

- 9 147.3.9 Change Order Approvals

- 10 147.3.10 Guardrail and Guard Cable Repair

- 11 147.3.11 Request to Subcontract Work (Form C-220)

MoDOT uses a contracting process called Job Order Contracting (JOC). This contracting process allows MoDOT to award fixed price construction contracts with indefinite delivery and indefinite quantity (ID/IQ) at individual work locations within the project limits. ID/IQ is governed by FHWA through 23 CFR 635 Subpart F. JOCs are typically used for on-call maintenance repair contracts, including asphalt and concrete pavement repair, guardrail and guard cable repair, bridge repair and fence repair. JOCs can be used for other construction and maintenance contracts. All non-standard JOCs (see list of standard JOCs and links in box below) regardless of funding source, shall be submitted to Engineering Policy Services for review of contractual compliance, constructability, and federal reimbursement eligibility, prior to PS&E submittal.

The JOC bid proposal must specify the minimum and maximum program budget to be awarded during a specified contract term. MoDOT is not bound, however, to issue a minimum or maximum number of job orders during the contract term. It is MoDOT’s overall intent though to meet the anticipated maximum budget specified in the contract.

JOCs shall have a Disadvantaged Business and Enterprise (DBE) goal set by MoDOT’s External Civil Rights. See EPG 146 for additional information.

All JOCs shall be reviewed for NEPA compliance. A Request for Environmental Services (RES) shall be submitted to the Environmental Section at the appropriate project development stage. Job Order Contracts (JOCs) are allowed one RES submittal, a Final RES, submitted annually for each renewal cycle, because they do not change significantly. See EPG 127.1 Request for Environmental Services for additional information.

JSP Packages for Asphalt Pavement Repair, Bridge, Concrete Pavement Repair, Fence, Guard Cable and Guardrail

Contact a Design Liaison for additional guidance.

147.3.1 Fixed Unit Price List and Non-Fixed Cost Items

Fixed Unit Price List. A fixed unit price list containing unit prices for the various items of work for each job order is included in the JOC bid proposal. Fixed unit prices are for complete and in-place construction, including all labor, equipment and material required to complete the construction task. All labor, material, equipment and work required by a specification shall be considered part of the fixed unit price, unless otherwise stated elsewhere in the contract.

Non-Fixed Cost Items. These are items of work for which a description and fixed cost is not set forth in the pay item list. Payment for non-fixed cost pay items will be determined in accordance with Sec 109.4.2, 109.4.3, or 109.4.4. Non-fixed cost pay items will be paid using an Adjustment Factor of 1.000. The approval level for non-fixed cost pay items shall be as indicated in EPG 109.12 Change Orders except that the Budgeted Amount shall not be exceeded without approval from the Chief Engineer.

147.3.2 Adjustment Factor

The contractor will bid an Adjustment Factor that includes business and construction related costs as defined below. It is the responsibility of the contractor to verify the fixed unit prices provided in the contract and to modify their bid for the adjustment factor accordingly.

Business Costs. Business related costs consist of profit, overhead costs, subcontractor profit and overhead, taxes, finance costs, and other costs including but not limited to;

- a. insurance, bonds and indemnification

- b. project meetings, training, management and supervision

- c. project office staff and equipment

- d. employee or subcontractor wage rates that exceed prevailing wages

- e. fringe benefits, payroll taxes, worker’s compensation, insurance costs and any other payment mandated by law in connection with labor that exceeds the labor rate allowances.

- f. business risks such as the risk of low than expected volumes of work, smaller than anticipated job orders, poor subcontractor performance, and inflation or material cost fluctuations.

Construction Costs. Construction related costs include but are not limited to;

- a. personnel safety equipment

- b. security requirements

- c. excess material waste

- d. daily and final clean-up

- e. costs resulting from inadequate supply of materials, fuel, electricity, or skilled labor

- f. costs resulting from productivity loss

- g. working in extreme and adverse weather conditions

- h. any other discreet items of work required to complete a particular job order.

General Costs. The above lists are not exhaustive and are intended to provide general examples of cost items to be included in the contractor’s Adjustment Factor as defined in the contract.

147.3.3 JOC Development: Job Special Provisions and Plan Sheets

MoDOT Bidding and Contract Services (BCS) conducts an annual internal MoDOT meeting to discuss lessons learned from previous year’s on-call contracts. Design staff incorporates changes into the next years contracts, and updates the job special provision (JSP) templates] for distribution to the districts.

The BCS section also updates the fixed costs to reflect the new market value. In the event the costs change significantly, the BCS section coordinates with industry to ensure the fixed costs are satisfactory. The fixed costs in the draft proposals should not be adjusted by the districts, without prior input from the BCS section. It is important to have agreement on the fixed unit price list with industry to eliminate any outliers that could cause contractors to bid risk in the adjustment factor.

In addition, no additional items of work should be added without first coordinating with the BCS section. Our experience to date has shown that adding specialty items of work may discourage contractors from bidding on a typical maintenance contract because the specialty work has to be subcontracted out for additional costs. Many times, specialty items of work or items of work not identified in the list of fixed costs are better managed by negotiating a price with the JOC contractor. Establishment of pricing for any non-fixed cost pay items will be in accordance with Sec 109.4.2 or 109.4.3 of the Missouri Standard Specifications for Highway Construction. If no agreement to pricing can be made then the work will proceed with payment for non-fixed cost items under Sec 109.4.4.

The JOC contracts include contractor-furnished Traffic Control Plans (TCP) as on option, but the district may choose to provide the traffic control with MoDOT forces depending on availability.

Example TCP plans for the Job Order Contracts exist as seed files in ProjectWise. These example plans are based on what has been used on past contracts and are for example purposes only. Some of the traffic control scenarios may not apply to all districts so each district should ensure changes to the Traffic Control Plans are also changed in the JSP template. If there are revisions to the JSP template, the district should identify the revisions to the BCS section at the time of Plans, Specifications & Estimate (PS&E) submittal.

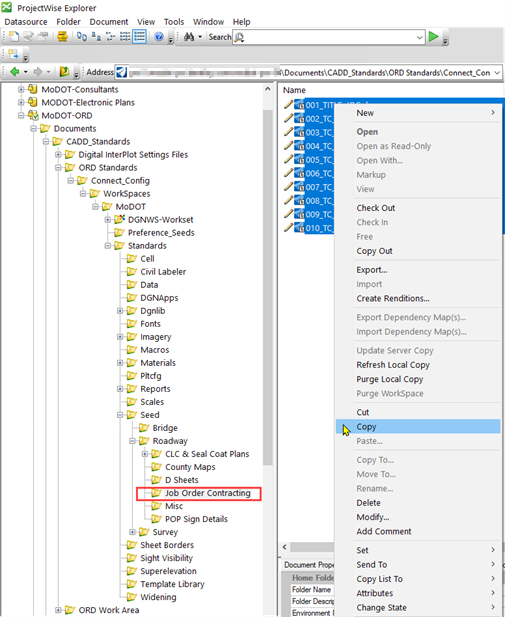

The JOC_TCP files are located in ProjectWise at \Documents\CADD_Standards\ORD Standards\Connect_Config\WorkSpaces\MoDOT\Standards\Seed\Roadway\Job Order Contracting\

All district ProjectWise users will have read-only access to the files.

The following is the process for obtaining a clean copy of all the files at one time:

- Select all of the files, right-click and select Copy.

- Then right-click in the job directory and select Paste.

147.3.4 Issuing Job Orders

The engineer will collaborate with the contractor when developing an individual job order. At any given time the contractor may be performing more than one job order.

The total cost of an individual job order will be determined by multiplying the fixed unit prices of each fixed cost pay item by the appropriate quantity and then multiplying the total cost of all pay items by the appropriate adjustment factor.

Example Job Order

| Item Description | Fixed Unit Price | Quantity | Price |

|---|---|---|---|

| SP125C (PG70-22) Per Ton (100.1-500 Tons) (Over 9 feet wide) | $84.00 | 425.6 tons | $35,750.40 |

| Tack Coat | $3.70 | 160 gal | $592.00 |

| Mobilization – Coldmilling & Resurfacing (15 - 1000 Tons) | $5,000.00 | 1 each | $5,000.00 |

| Milling Per SY (2 In. or less Thick) | $2.10 | 3200 sy | $6,720.00 |

| Subtotal: | $48,062.40 | ||

| Normal Work Factor | 1.150 | - | - |

| TOTAL: | $55,271.76 | ||

147.3.5 Term Extension of Job Order Contracts

All JOC contracts include the option for a mutually agreeable one year term extension. The contract may be extended under the original terms and contract prices for a maximum contract term of two (2) years. The district should contact the BCS section by November 1 to evaluate and discuss whether the JOC should be renewed. Is the district satisfied with performance of the contractor? Are the existing bid prices reasonable? Is it the right business decision to renew the contract? If the option for extending the contract is exercised by MoDOT, a change order will be issued to extend the contract to the new term limits.

The following are the guidelines for extending the term of a Job Order Contract for an additional year for a maximum two year term.

- In order for the contract to be extended, the project must contain the language in the Term of Contract JSP that allows for a one year extension.

- If MoDOT desires to renew the contract, the contractor will be given written notification (e-mail is acceptable) of the extension no later than December 1 of the current contract year.

- The contractor shall provide written notification (e-mail is acceptable) of acceptance or rejection of the extension of the contract no later than January 1 of the current contract year.

- If the option for extending the contract is exercised by MoDOT, a time adjustment change order will be issued by the RE to extend the contract to the new term limits. Use the following statement as the reason for the extension:

- “In accordance with JSP xx Term of Contract, the contractor and the Commission hereby mutually agree to extend the contract to the maximum allowable term of two (2) years. The end of the contract term shall be (insert date). All original terms and contract prices shall apply with the exception of wage rates. Contract and subcontract employees shall be paid the current prevailing wage rates at which time the contract extension is executed. The anticipated budget amount in JSP xx Contract Award is hereby raised to $(insert an amount that is two times the 'anticipated budget' listed in the Contract Award JSP). The contractor shall increase the amount of the Performance Bond to 100% of the revised anticipated budget.”1

- 1 Text in red indicates information that must be supplied by the users themselves.

- The agreed letters or emails from both parties shall be on file in eProjects as supporting documentation to the time adjustment change order. A final quantity change order will be issued after completion of the second term.

- Per EPG 147.3.9, the one-year term extension change order should be District level approval (this is an exception to all other time extension change orders, which require Division level approval).

- The RE must notify the contractor that the performance contract bond shall be increased to an amount equal to the original contract amount plus the extended contract amount (i.e., the original bond amount is generally just doubled). This can be accomplished by issuing a rider to increase the original bond to the new anticipated contract amount, or by issuing a new bond for double the original contract amount (i.e., if the original contract is $2 million, an increase rider should be issued for $2 million or a completely new bond for $4 million). A change order to increase the contract amount is not necessary because the new performance bond becomes part of the executed contract. The RE should scan the new performance bond and save it to the project file in eProjects. The paper copy of the new embossed performance bond should be submitted to the Division of Construction and Materials for storage with the original contract. The RE should submit an email request to COCCContracts@modot.mo.gov for review of the new bond. The email should include the contract ID, the reason for the review (JOC extension), and separate links to the new bond, the original bond and the signed change order for the one-year extension.

- The district should notify the BCS section and District Planning staff by January 15 of the intent to extend the contracts and request the projects be delayed during the annual STIP update. The following information should be provided:

- a. Current project numbers being extended.

- b. Future project numbers in the STIP that will be delayed to a later state fiscal year because of the extension.

- JOCs that will not be extended should be closed out in AWP at the end of the first year contract term.

- JOCs that are extended will be closed out in AWP at the end of the second year contract term. The district shall close out the contract following the Closing JOC Contracts guidelines below.

147.3.6 Closing JOC Contracts

- Any JOCs that will not be extended should be closed out in AWP at the end of the first year contract term. Renewed contracts are closed out in AWP at the end of the second year contract term.

- Check the actual cost charges to make sure they are correct and request journal vouchers from Financial Services for corrections.

- Proceed with final close out in AWP.

- Submittal of a Materials Summary is not required for Job Order Contracts.

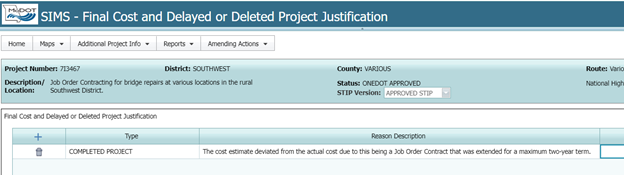

- After close out of extended JOC contracts, enter the following Reason Description for cost differences greater than 10% into SIMS, Final Cost Justification page with the type of Completed Project: “The cost estimate deviated from the actual cost due to this being a Job Order Contract that was extended for a maximum two-year term."

147.3.7 Budget Adjustments for JOC Contracts

The contract budget adjustment will occur after the contract is complete. For increases to budgeted amounts on active JOC projects, see EPG 147.3.9 for Level 4 change order preparation.

147.3.8 Delayed JOC Projects

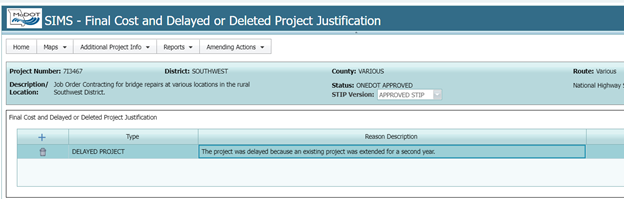

If a JOC project is delayed from the current state fiscal year to a later STIP year, enter the following standard reason into SIMS, Final Cost Justification page with the type of Delayed Project: “The project was delayed because an exiting project was extended for a second year.”

147.3.9 Change Order Approvals

Job Order Contracts are unique in that they do not include a defined amount of work, but rather they are agreements to perform work on an as-needed basis, not to exceed the Commission-approved budgeted amount. Payment is determined by applying an adjustment factor to fixed unit prices as opposed to standard contracts that have unit bid prices for each pay item. Also, JOCs do not have a total contract amount based on plan quantities, but rather have a one-year budgeted amount that has been approved by the Commission. For contracts that include an optional second-year term, the Commission authorizes the district to expend two times the budgeted amount if the contract is extended to two years. Exceeding the budgeted amount requires approval by the Chief Engineer. Due to the unique nature of JOCs, the change order approval levels will need to be manually set in AASHTOWare and contract administration of change orders shall be as follows:

- Budgeted Amount and Cost Overruns. It is important to understand that the Bid Total in the front of the contract is not the budgeted amount. The Bid Total is only used to determine the winning bidder. Reference the CONTRACT AWARD section of the Job Special Provisions to determine the budgeted amount for the first year term of the Job Order Contract. For contracts that are not extended into a second year term, the Resident Engineer is authorized to expend up to that budgeted amount in the first year without issuance of a change order to increase the budgeted amount. If the contract has an optional second year term, and both parties are in agreement to extend the contract into the second year, the RE is authorized to expend two times the budgeted amount over the two-year term without issuance of a change order to increase the budgeted amount. The budgeted amount for the first year can be exceeded in the first year as long as the contract is extended to a second year and you do not exceed 2x the budgeted amount. If there is a need to increase the budgeted amount (one year or two-year), the RE shall issue a Level 4 change order prior to ordering the work, except that emergency repairs such as guardrail and guard cable shall not be delayed due to an unexpected overrun of the budget.

- Non-Fixed Cost Pay Item. The approval level for non-fixed cost pay items shall be as indicated in EPG 109.12 Change Orders except that the Budgeted Amount shall not be exceeded without approval from the Chief Engineer.

- Contract Extensions. See EPG 147.3.5 Term Extension of Job Order Contracts for guidance on extending a JOC to a second year term. Per EPG 109.12.4, time adjustment change orders require division level approval, but when a JOC includes a provision that allows a one-year time extension, approval can be made at the district level. File the agreed letters (or emails) from both parties for supporting documentation in eProjects. If a time extension past the second year becomes necessary for any reason, contact the CM division for approval prior to issuance of a change order.

- Final Change Order. Upon completion of the Job Order Contract, a final change order should be issued to adjust the final contract amount to equal the total of all Job Orders issued during the term of the contract. Use the following statement for the reason: “This final change order adjusts the final contract amount to the sum of all completed Job Orders.” This Final Change Order should be approved at the district level unless the budget amount was exceeded (see Budgeted Amount and Cost Overruns for guidance on budget overrun change orders).

147.3.10 Guardrail and Guard Cable Repair

Each district should designate a responsible person in charge of overseeing the repair and maintenance of the guardrail and guard cable systems within the district. This person will serve as the district contact, be the expert on the maintenance and repair for the district and participate in statewide discussions with divisions and other district contacts. The repair of damaged guardrail and guard cable should primarily be completed by contract forces through a Job Order Contract (JOC). Maintenance forces may be utilized to perform some minor maintenance and/or repair work when the district deems that to be the more feasible option and the work is completed under the general supervision of the district’s designated responsible person. Maintenance forces may also be utilized to place temporary delineation immediately following guardrail damage per EPG 147.3.10.1. It is recommended that a professional engineer be assigned to administer the JOC. For purposes of this article, duties of the contract administrator may be delegated to a competent person working under the general direction of the professional engineer overseeing the JOC.

Districts should establish a process to identify and report damaged guardrail and guard cable (GR/GC) on routes throughout the district to ensure the repair is not unduly delayed. Regional contacts shall be utilized and populated in the MoDOT contacts map for use by statewide customer service representatives. A description of the damage, including location, and detailed photos, should be promptly submitted by the regional contacts to the contract administrator of the JOC.

Based on the information provided, the contract administrator shall promptly issue a Job Order to the contractor to initiate the repair. For routine repairs, the Notice to Proceed date should be established as 3 business days following the date of issuance of the Job Order to allow the contractor the time needed to obtain utility locations prior to starting the work. The contract administrator should monitor the timeliness of the repair and assess the appropriate liquidated damages when the contractor fails to complete the work within the allowable time, or any additional time granted due to an excusable delay.

147.3.10.1 Initial Response and Delineation of Damaged Guardrail

Terms of the Job Order Contract (JOC) for repair of guardrail and guard cable include designation of responsibilities prior to mobilization of the JOC contractor. Specifically, MoDOT and/or other first-response entities are responsible for securing the scene following an accident, which might include such tasks as removing debris from the roadway and removing any parts from the guardrail/guard cable system that protrude into a lane of traffic. In addition, MoDOT maintenance forces shall provide temporary delineation of damaged guardrail as soon as practical when the damage is within 15 feet of the travel way and is deemed a potential risk (see examples below). Delineation, when required, shall include placement of a minimum of five channelizers (Trim Lines) in advance of the damaged areas, spaced at 50-foot intervals. If shoulder width allows, the channelizers should be placed on a slight taper to channel motorists away from the damaged areas. The delineation should be left in place until the repair is complete and then removed by MoDOT forces as soon as possible after the repair. Delineation is generally not required for damage to guard cable systems but may be considered when the damage is in close proximity to traffic.

Examples of guardrail damage that warrants delineation:

- An obstacle has been exposed due to missing or non-functional guardrail.

- Guardrail end terminals have been damaged to the extent they appear to be non-functional (for example, the head of the terminal has been removed or is otherwise out of position).

- The end of a guardrail panel is exposed (for example, it is pointing towards traffic).

- Open gaps where the guardrail has been obliterated in the crash or otherwise removed.

- Damaged rail that protrudes onto the shoulder or might otherwise be deemed a risk.

- Sharp edges or protruding parts in locations frequented by pedestrians or bicyclists (caution tape might be more appropriate here).

147.3.10.2 First Priority Repair for Guardrail

Terms of the Job Order Contract require the contractor to reasonably expedite completion of all repairs (i.e. within 7 days of the Notice to Proceed). Contract provisions allow a limited number of guardrail repairs to receive priority status, thus requiring an expedited mobilization and less time for completion. When it has been determined by the contract administrator the safety of the public may be unduly compromised due to the nature of the damaged guardrail or end terminal, the repair should be designated as a First Priority repair per EPG 147.3.10.2.1. Immediately following this determination, the administrator should notify the contractor by phone to prepare for the pending Job Order and a follow-up email should be sent to document the notification and provide preliminary information. This notification prompts the contractor to initiate an emergency clearance of utilities and to begin planning the work so the repair work can begin as soon as possible. The contract administrator will issue the Job Order as soon as possible following notification, but no later than 48 hours. The contract terms require the contractor to begin the work within 24 hours of issuance of the Job Order.

If work on a First Priority repair causes delay to one or more pending routine Job Orders, the contract administrator should grant the appropriate amount of additional time to complete the affected routine repair(s) that were postponed.

147.3.10.2.1 Designation of First Priority Status

Engineering judgment should be used when designating a repair as First Priority. This status is reserved for a limited number of guardrail incidents that the administrator deems to be in critical need of repair. Below is a list of common damages that would warrant consideration of utilizing the First Priority status as well as a list of relevant factors that should be considered when making this determination. For example, some low volume routes have existing structures where guardrail is not warranted, therefore a critical need on this route may not take priority over a routine repair on an interstate route.

Common damages that prompt consideration of First Priority:

- Exposure of traffic to a blunt end or other extreme obstacle (bridge abutment, column, barrier wall, body of water, vertical drop, etc.)

- Damaged end terminals that appear to provide no protection from the rail end (for example, head is missing or is no longer covering the rail end, etc.)

- The end of a guardrail panel is exposed (for example, an unprotected rail end is elevated and pointing towards traffic).

- Open areas where the guardrail has been wiped out or otherwise removed, and a obstacle has been exposed.

Factors to consider when determining First Priority Status:

- Traffic volume

- Posted speed limit

- Frequency of crashes at or near the location

- Severity of the exposure

- Proximity of the exposed obstacle to traffic (i.e. shoulder width)

- The lack of warrants for prevalent safety features elsewhere on the route

- Potential risks of a work zone in extreme weather conditions

- Ability to adequately delineate and/or mitigate the obstacle.

147.3.11 Request to Subcontract Work (Form C-220)

Subcontracting of work on job order contracts is allowable for approved subcontractors. For example, it is not uncommon for JOC contractors to hire a subcontractor to perform a support function such as traffic control. Since JOCs do not have planned work or unit prices, the contractor should not list any items when submitting Form C-220. They should type a basic description of the subcontracted work in the Description field. Approved subcontractors should be entered into AWP by project office staff and no items will be listed. The Resident Engineer should monitor the use of subcontractors and ensure that the prime is self-performing at least 30% of the work.