Category:173 Erosion Control for Maintenance Operations

MoDOT takes great pride in being a good steward of the environment. As part of Maintenance operations, we must strive to protect, conserve and enhance the environment while maintaining and operating a complex transportation infrastructure.

EPG 173 offers examples on how to maintain roadway slopes and ditches to prevent erosion and slides and how to repair slopes and ditches when they are impacted by slope erosion and slides. EPG 173.1 Regulations and Permits outlines the rules and regulations that set the boundaries for MoDOT’s actions. Typically, eroded ditches, slopes or stream banks have been repaired with rip-rap material to mitigate future erosion. The following articles outline specific examples on prevention and repair with step-by-step pictorial overviews.

Contents

- 1 173.1 Regulation and Permits

- 1.1 173.1.1 Do You Need a Section 404 Permit?

- 1.2 173.1.2 User Notes and Cautions

- 1.3 173.1.3 MT Activities that DO NOT Require a Section 404 Permit

- 1.4 173.1.4 MT Activities that are Covered Under Existing Nationwide or General Permit that DO NOT Require Pre-construction Notification to the Corps

- 1.5 173.1.5 MT Activities that Require Pre-construction Notification to the COE

- 1.6 173.1.6 Regulatory Conditions for Working in Streams/Wetlands: NWP, Section 401 Water Quality Certification General Conditions

- 1.7 173.1.7 Summary

- 2 173.2 Slide Detection and Repair

- 3 173.3 Slope Erosion Prevention and Sediment Control

- 4 173.4 Ditch Clean Out and Stabilization

- 5 173.5 Streambank Stabilization

- 5.1 173.5.1 Governing Regulations

- 5.2 173.5.2 Project Name: Spring Creek Bridge Repair

- 5.3 173.5.3 Project Name: Little Creek Streambank Stabilization

- 5.4 173.5.4 Project Name: Galey Branch Box Culvert Repair and Streambank Stabilization

- 5.5 173.5.5 Project Name: Galey Branch Creek Stabilization

- 5.6 173.5.6 Project Name: Mills Creek Stabilization

- 5.7 173.5.7 Project Name: Mills Creek Streambank Stabilization

- 5.8 173.5.8 Project Name: Indian Creek Stabilization

- 5.9 173.5.9 Project Name: Sees Creek Realignment

- 6 173.6 Seed Mix Formulas

- 7 173.7 Soil Fertility Techniques

- 8 173.8 References

173.1 Regulation and Permits

There are many laws in effect today that were enacted in an effort to protect the nation’s natural environment. These laws have a direct effect on the way MoDOT conducts business, as it is MoDOT’s commitment to remain environmentally responsible. One law in particular, the Clean Water Act (CWA), was enacted to protect the nation’s waters from pollutants. Sections 401, 402, and 404 of the Clean Water Act influence many of MoDOT’s day to day activities. The Department of Army Corps of Engineers (COE) administers Sections 401, 402 and 404 of the Clean Water Act. Specific COE district office location information is available.

173.1.1 Do You Need a Section 404 Permit?

Throughout the work descriptions below, you will notice a couple of recurring terms: Clean Rock Fill and Ordinary High Water Mark (OHWM or OHW). For the purposes of this article, these terms shall be defined as follows:

- Clean Rock Fill. You must use only graded rock, quarry-run rock and/or clean concrete rubble for rip-rap. The material must be reasonably well graded, consisting of pieces varying in size from 20 pounds up to and including at least 150 pound pieces. Generally, the maximum weight of any piece should not be more than 500 pounds. Gravel and dirt should not exceed 15% of the total fill volume. If you use concrete rubble, you must break all large slabs to conform to the well graded requirement, and remove all exposed reinforcement rods, trash, asphalt, and other extraneous materials before you place the rubble in the waters of the United States. Size and gradation requirements can be changed provided approval is received from the Corps’ Regulatory Branch prior to placement.

- Ordinary High Water Mark (OHWM or OHW). The term ordinary high water mark means that line on the shore established by the fluctuations of water and indicated by physical characteristics such as a clear, natural line impressed on the bank, shelving, changes in the character of soil, destruction of terrestrial vegetation, the presence of litter and debris, or other appropriate means that consider the characteristics of the surrounding areas.

173.1.2 User Notes and Cautions

- ANY WORK WITHIN JURISDICTIONAL WETLANDS WILL REQUIRE AUTOMATIC PRE-CONSTRUCTION NOTIFICATION TO THE US ARMY CORPS OF

ENGINEERS.

- Some streams have sensitive fish, mussels, and other species in them and as a result may have date restrictions of when MoDOT can work in the stream.

- When in doubt, ALWAYS contact the MoDOT Design-Environmental Section at (573) 526-4778 prior to starting your activity.

173.1.3 MT Activities that DO NOT Require a Section 404 Permit

- Hand-cutting (with a chainsaw) logs and brush that build up against our structures.

- Dipping out (with a trackhoe or equivalent piece of equipment) logs and brush that build up against our structures. NOTE: This work must be done without entering the stream channel with a tracked vehicle (you can enter the stream with a rubber tired vehicle, as long as you ARE NOT pushing material around), either from the high bank or the bridge/roadway, and the logs/brush must be placed in an upland location, where there is not a chance of them endangering our structure again.

- Rubber tired vehicle in the stream channel to dip out sand/silt/gravel material. You CAN NOT push material around with a loader or skid steer; you must use a bucket to DIP MATERIAL OUT.

- Placing clean rock fill or shaping a streambank (laying a bank back for stability) ABOVE THE ORDINARY HIGH WATER MARK.

173.1.4 MT Activities that are Covered Under Existing Nationwide or General Permit that DO NOT Require Pre-construction Notification to the Corps

- Streambank stabilization that can involve armoring a bank with clean rock fill or protecting the toe of a bank with clean rock fill. This includes stabilizing the banks behind culvert wing walls and on bridge spill fills (NOTE: This activity CAN NOT exceed 500 ft. in length and/or 1 cubic yard per running foot of fills below the ordinary high water mark (This work is covered under Nationwide Permit #13).

173.1.5 MT Activities that Require Pre-construction Notification to the COE

- Performing work in the channel with tracked equipment (tracked skid steer, trackhoe, etc.) to clean sediment (silt, sand, gravel, etc.) out of, or away from a structure. (Note: All material removed must be taken to and disposed of in an upland location and work CAN NOT EXCEED 200 ft. of stream length.) This work requires a Nationwide Permit #3.

- Performing work in the channel with a rubber tired vehicle (tired skid steer, backhoe, front-end loader etc.) and pushing the material in order to remove it. (Note: All material removed must be taken to and disposed of in an upland location and work CAN NOT EXCEED 200 ft. of stream length.) This work requires a Nationwide Permit #3.

- Placing clean rock fill and/or gabion baskets within the channel to stabilize culvert outlets or inlets. This work requires a Nationwide Permit #3.

- Placing clean rock fill and/or gabion baskets around scoured bridge piers. This work requires a Nationwide Permit #3.

- Streambank stabilization as discussed in the green section above that exceeds 500 ft. in length or 1 cubic yard per running foot of fills below the ordinary high water mark. This work requires a Nationwide Permit #13.

173.1.6 Regulatory Conditions for Working in Streams/Wetlands: NWP, Section 401 Water Quality Certification General Conditions

1. Missouri Water Quality Standards antidegradation requirements dictate all appropriate and reasonable Best Management Practices (BMPs) related to erosion and sediment control, project stabilization, and prevention of water quality degradation are applied and maintained (10 CSR 20-7.031(3)); for example, preserving vegetation, streambank stability, and basic drainage. BMPs shall be properly installed prior to conducting authorized activities and maintained, repaired, and/or replaced as needed during all phases of the project to limit the amount of discharge of water contaminants to waters of the state. The project shall not involve more than normal stormwater or incidental loading of sediment caused by project activities so as to comply with Missouri’s general water quality criteria (10 CSR 20-7.031(4)). Also refer to EPG 127.29 Stormwater and EPG 136.6.4.8 Stormwater and Erosion Control.

2. Temporary stream crossings shall be sized and placed appropriately and shall not create an impediment to the passage of aquatic organisms and/or sediment. This will ensure compliance with the Missouri Water Quality Standards general criterion requiring waters to be free from physical or hydrologic changes that would impair the natural biological community (10 CSR 20-7.031(4)(H)).

3. Stream channel modifications shall be avoided as much as possible and, if needed, shall be minimized. Where modifications are necessary for highway design safety or protection of state infrastructure, to the extent practicable, the project shall incorporate natural channel design features relative to a morphologically stable and appropriate stream channel and incorporate measures such as grade control, in-stream habitat, riparian plantings, etc. This will ensure compliance with the Missouri antidegradation requirement that waters of the state shall be maintained and protected (10 CSR 20-7.031(3)) under Missouri Clean Water Law, which provides the Department authority to adopt remedial measures to prevent, control, or abate pollution (Section 644.026.1(9)).

4. The following materials are not suitable where contact with water is expected and shall not be used due to their potential to cause violations of the general criteria of Missouri’s Water Quality Standards (10 CSR 20-7.031(4)): earthen fill, gravel, and broken concrete where the material does not meet the Suitable Material specifications stated in the “Missouri Nationwide Permit Regional Conditions” in locations where erosive flows are expected to occur on a regular basis, such as streambanks and/or lake shorelines; asphalt; concrete with exposed rebar; tires, vehicles or vehicle bodies, and construction or demolition debris are solid waste and are excluded from placement in the waters of the state, but properly sized, broken concrete without exposed rebar is allowed; liquid concrete, including grouted riprap, if not placed in forms as part of an engineered structure; material containing chemicals that would result in violation of Missouri Water Quality Standards general criteria (10 CSR 20-7.031(4)) or specific criteria (10 CSR 20-7.031(5)).

5. Waste concrete or concrete rinsate shall be disposed of in a manner that does not result in any discharge to the jurisdictional water ways. This will ensure compliance with the Missouri Water Quality Standards general criteria requiring waters be free from unsightly bottom deposits (10 CSR 20-7.031(4)(A)); substances resulting in toxicity (10 CSR 20-7.031(4)(D)); and physical, chemical, or hydrologic changes that would impair the natural biological community (10 CSR 20-7.031(4)(H)).

6. During construction, clearing of vegetation shall be kept to the minimum necessary to accomplish the project except for the removal of invasive or noxious species and placement of ecologically beneficial practices. This will ensure compliance with the Missouri antidegradation requirement for BMPs (10 CSR 20-7.031(3)).

7. Care shall be taken to keep machinery out of the water way as much as possible. If work in the water way is unavoidable, it shall be performed in a way that minimizes the duration and amount of any disturbance to banks, substrate, and vegetation to prevent increases in turbidity. Fuel, oil and other petroleum products, equipment, construction materials and any solid waste shall not be stored below the ordinary high-water mark at any. All precautions shall be taken to avoid the release of wastes or fuel to streams and other adjacent waters as a result of this operation. This will ensure compliance with the Missouri Water Quality Standards antidegradation requirement for Best Management Practices (10 CSR 20-7.031(3)) and Missouri Water Quality Standards general criteria requiring waters be free from substances preventing beneficial uses (10 CSR 20-7.031(4)(A)); substances causing unsightly color or turbidity (10 CSR 20-7.031(4)(C)); and physical, chemical or hydrologic changes that would impair the natural biological community (10 CSR 20-7.031(4)(H)).

8. Disturbed riparian areas, banks, etc., shall be restored to a stable condition to protect water quality as soon as possible. This will ensure compliance with the Missouri antidegradation requirement for BMPs (10 CSR 20-7.031(3)).

9. All efforts shall be made to minimize exposure of unprotected soils. To the best of MoDOT’s or its contractor’s ability, project activity shall be conducted at times of little or no rainfall to limit the amount of overland flow as well as sediment disturbance and transport caused by heavy equipment. This will ensure compliance with the Missouri antidegradation requirement for BMPs (10 CSR 20-7.031(3)) and general criteria (10 CSR 20-7.031(4)).

10. Any stockpiled excess material resulting from the project shall be managed with appropriate BMPs or removed from the site and placed beyond the high bank on a non-wetland site. This will ensure compliance with the Missouri Water Quality Standards antidegradation requirement that waters of the state shall be maintained and protected (10 CSR 20-7.031(3)) and general criterion requiring waters to be free from physical, chemical, or hydrologic changes that would impair the natural biological community (10 CSR 20-7.031(4)(H)).

11. Petroleum products spilled into any water or on the banks where the material may enter waters of the state shall be cleaned up immediately and disposed of properly. Spills of any amount of petroleum in a waterway shall be reported as soon as possible, but no later than 24 hours after discovery, to Missouri Dept. of Natural Resources’ Environmental Emergency Response website or phone line at (573) 634-2436. This will ensure compliance with Missouri Environmental Improvement Authority (Section 260.015, RSMo) to provide for the conservation of state water resources by the prevention of pollution and proper methods of disposal and Missouri Water Quality Standards general criteria requiring waters be free from substances that prevent maintenance of beneficial uses; cause unsightly color, turbidity, or toxicity; and/or impair the natural biological community (10 CSR 20-7.031(4)).

173.1.7 Summary

Additional information on MoDOT’s erosion and sediment control guidelines can be found at EPG 806 Pollution, Erosion and Sediment Control.

173.2 Slide Detection and Repair

173.2.1 Governing Regulations

CWA Section 402 (Land Disturbance). If repair of a slide involves earth moving and “damage to the root zone” of more than one acre, compliance with MoDOT’s state operating permit for area wide land disturbance will be required. A site-specific stormwater pollution prevention plan (SWPPP) will be required. The SWPPP shall outline sediment controls such as perimeter silt fence and ditch check to be installed to keep the sediment from leaving the job site while slope repair will be occurring. Regularly scheduled and post runoff inspections will be required once the land disturbance operation begins until a final stabilization is achieved.

CWA Sections 401 and 404. If the slide involves a regulated (jurisdictional) stream or wetland it may be necessary to obtain Department of Army Corps of Engineers (COE) authorization before doing work in and around the stream or wetland.

173.2.2 Project Name: Bourbon Slide Repair

Location: I-44 North Outer Road, West of Route J in Crawford County

Date: July 2009

Materials Used: 100% Coconut Fiber Erosion Blanket, Straw Wattles, Fill dirt from local maintenance lot

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Slope failures are common problems in this area due to unseasonal amounts of rainfall and soil conditions. This area slid off near the shoulder which caused a potential hazard. A dozer was used to cut a bench into the new slope to solid ground, new fill dirt was hauled in and a slope was built back in lifts as it was compacted with a dozer. The slope was tracked and seeded with straw wattles and erosion blankets to slow down runoff and to protect the slope. Grasses were established with no issue of erosion or settling after two years.

173.2.3 Project Name: Cuba Slide Repair

Location: I-44 Mile Marker 208, end of on ramp westbound

Date: September 2007

Materials Used: 4 Gabion Baskets 9’x3’x3’, 3 loads of 4-6 in. Gabion Rock for baskets, 4 loads of shot rock for slope, partial load of base rock used along shoulders edge.

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The slide was located on I-44 at the end of ramp along the edge of shoulder. At the bottom of the slope was a concrete ditch which was filled by silt that was caused by the slide. The toe of the slope was cut back from the edge of concrete ditch. Gabion baskets were installed behind the concrete ditch and secured with T-posts to prevent the baskets from moving. The gabion baskets were filled with rock (4 in. to 6 in. without fines). Shot rock was then placed behind the gabions to the shoulder’s edge. Next to the concrete shoulder, base rock was installed over the shot rock. The project has performed well and rock has become vegetated.

173.2.4 Project Name: Paris Slide Repair

Location: Route 24 East of Paris, Monroe Couunty

Date: July 2009

Materials Used: 3600 cubic yard rock fill

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. This slide developed over time and was one of three in the vicinity. The work was completed by a contractor who excavated around 5000 cy (around 400 loads of material) from the site in 5 (10-12 hour) working days. It took 3 working days to place 3600 cy of rock fill (110 loads). Following the spec book, the rock was placed in layers and compacted with the track hoe. The trucks would unload the rock on the haul road, and then the contractor would push the rock into the fill site where the track hoe operator would pull the rock down so that the rock was able to be compacted and placed in layers. Another bulldozer was used at the waste site where the excavated dirt was being placed. The finished project was 300 ft. long and approximately 50 ft. tall.

173.3 Slope Erosion Prevention and Sediment Control

173.3.1 Governing Regulations

- CWA Section 402 (Land Disturbance). There are no anticipated DNR issues.

- CWA Sections 401 and 404. There are no anticipated Corps of Engineers issues.

173.3.2 Project Name: Cuivre River Bridge Embankment

Location: Route E, West of Silex, Lincoln County

Date: March 2010

Materials Used: Approximately 150 pounds of grass mixture seed and erosion control blanket (nine 8’ rolls and four 4’ rolls).

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. This repair took place on the North Fork of Cuivre River. The project involved installing erosion prevention after repairs were made to scour at the bridge ends. The vehicles performing the scour repairs roughed up the soil surface and eliminated the existing vegetation. An incarcerated work release crew provided the labor to install the erosion repair.

173.4 Ditch Clean Out and Stabilization

173.4.1 Governing Regulations

CWA Section 402 (Land Disturbance). Ditch cleanout is usually not an activity that involves “land disturbance” and would not require a DNR State Operating Permit. (IMPORTANT: If cleanout involves excavation of soil that is contaminated by petroleum products or other types of regulated materials a multitude of other laws may be involved. Contact the Design-Environmental Section first). If the freshly cleaned out ditch has the potential to generate erodible slopes that could produce sediment in runoff, appropriate BMPs would include ditch checks in the road ditch at locations where runoff would be expected to enter streams or drainageways at culvert/bridge outlets or inlets. Excavated excess material must not be disposed of in wetlands or other locations where it is likely to end up in a stream or ditch.

CWA Sections 401 and 404. Typically, MoDOT ditches are not regulated waters of the U.S., and therefore ditch cleanouts and stabilization would usually not require authorization under Section 404. However, it is important to note that some MoDOT ditches are actually captured streams and may therefore be considered regulated waters U.S. under Section 404 of the Clean Water Act, and work within these regulated ditches could therefore require a Section 404 permit. *Something to look for is if a stream enters the ditch from off ROW.*

173.4.2 Project Name: Three Dimensional Ridge Ditch Checks

Location: Route 60 Carter County Construction Project

Date: March 2010

Materials Used: 100- 39” Three Dimensional ditch check sections and anchor pins, erosion blanket was installed by construction contractor

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Purpose of the work was to test the effectiveness of the three-dimensional ridge ditch checks to triangular silt ditch checks that is traditionally used on construction projects. Three dimensional ridge ditch checks were installed by MoDOT crews on a 1/2 mile stretch of the Route 60 expansion construction job in Carter County. Twenty-five devices were installed over erosion blanket material with metal spikes. The devices performed well, allowed grasses through the ditch check. There were no failures after the ditch checks were removed. Three-dimensional devices can be reused if care is taken with removal. For best results, refer to manufacturer’s recommendations for placement.

173.4.3 Project Name: Compost Berms

Location: Route 65, Taney County

Date: April 2009

Materials Used: Compost and Erosion Control Blankets

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The former District 8 started installing large compost berms in April 2009. These berms consisted of about 5-6 cubic yards of half decomposed wood chips from tree trimming operations, covered with erosion control blankets.

173.5 Streambank Stabilization

173.5.1 Governing Regulations

CWA Section 402 (Land Disturbance). If land disturbance activities exceed one acre a separate State Operating Permit from DNR will be necessary. In that case, BMPs will be identified in the Section 402 Permit application.

CWA Sections 401 and 404. In general, streambank stabilization activities will require authorization under Section 404 of the Clean Water Act unless all work is done above the Ordinary Highwater Mark (OHWM).

173.5.2 Project Name: Spring Creek Bridge Repair

Location: Bridge No. P0418 Route D, Sullivan County

Date: December 2008

Materials Used: 17 gabion baskets, gabion rock

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Bridge Maintenance Engineers will inspect bridges for erosion and scour, identify needed repairs, specify treatments and obtain COE permits for required work.

173.5.3 Project Name: Little Creek Streambank Stabilization

Location: Bridge No. A1231, Route 17 Howell County

Date: February 2009

Materials Used: 20 Gabion Baskets 6’x3’x3’, Gabion rock, shot rock

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The abutment under the bridge was eroding. This caused the H piles to become exposed. The project fell under the GP-41 permit. The first step was for the district bridge crews to protect the pilings by placing concrete around them. Next, the district roadside crew installed gabion baskets which act as a barrier to protect the piles and act as a retaining wall to hold shot rock on the abutment slope.

173.5.4 Project Name: Galey Branch Box Culvert Repair and Streambank Stabilization

Location: Route 61, Pike County

Date: October 2010

Materials Used: 4 gabion baskets filled with 40 tons of rock and approximately 300 tons of rock for streambank repair.

Contact Information: Paul Denkler, (573) 526-3282

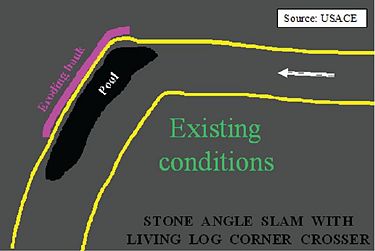

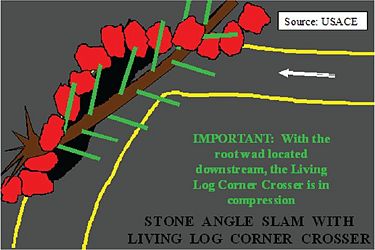

Project Summary. The project was undertaken to repair erosion around wing walls and scour both immediately below the box outlet and downstream. Work was performed under Section 404 Nationwide Permits #13 (streambank stabilization for erosion around wing walls) and #3 (fill placed within the stream for scour below the box). The repairs were performed by routine maintenance and the special crews. Gabion baskets were placed at the box outlet and large rocks were used downstream of the baskets and on top to help anchor them in place. The slopes around the box were seeded and protected with erosion blanket. Downstream of the box culvert the stream made a 90 degree turn and scour was occurring at the turn. A point bar had developed on the side opposite of the scour. The COE suggested using a “stone angle slam with a living log crosser” to repair the erosion and protect the streambank. This work was performed under a Nationwide #13 permit. Since there was not a large log available, the crew used multiple smaller logs from willows removed from in front of an upstream box culvert. Because they were small, large stones were placed over the entire log bundle to help hold them in place. The logs will sprout and prevent further scour.

173.5.5 Project Name: Galey Branch Creek Stabilization

Location: Route U, Pike County

Date: October 2010

Materials Used: 1,200 tons of clean rock, geotextile.

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Streambank erosion was caused by migration of the main channel to the south jeopardizing the road bed. A point bar developed on the north side of the stream with many willows, cottonwoods and sycamore saplings. Repairs were performed under Section 404, Nationwide Permits #13 and #27. Work was performed by routine maintenance and special crews. Large stones were placed along the toe of the slope and keyed into the bank at both ends of the repair. A space was left behind the large stones and filled in with gravel and sediment. Living willows were removed from the point bar. Clean rip-rap was then used to cap the removed sediment and mixed material was placed on the slope above ordinary high water to allow vegetation to develop. Large stone weirs were placed in the bed facing slightly upstream to direct the flow of water away from the toe of the slope. The willows will be allowed to sprout through the stones and further protect the streambank. The willows will be outside of the roadway clear zone.

173.5.6 Project Name: Mills Creek Stabilization

Location: Route O, Ralls County

Date: Not known

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Grouted rip-rap should not be used to repair streambanks. Over time, the toe of the slope will erode creating a void beneath the repair. The entire slab of grouted rip-rap may wash out during a large flood event. Furthermore, the COE does not allow grouted rip-rap as an acceptable repair option.

173.5.7 Project Name: Mills Creek Streambank Stabilization

Location: Route O, Marion/Ralls County

Date: April 2010

Materials Used: 550 tons of clean rock (400-1000 lb), geotextile.

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The streambank was eroding due to migration of the stream into toe of slope jeopardizing a nearby road bed. A sediment bar had developed on the opposite bank where willows were sprouting on the bar. Repairs were performed under Section 404 Nationwide Permits #13 and #27. Work was performed by routine maintenance. When the stones were dumped, the geotextile material was ripped and much of the material ended up wadded under the rip-rap. Over time, a sediment bar developed at the toe of the slope and the channel migrated to the opposite side of the stream. Willows will be allowed to sprout in the bar and along the toe of the slope to protect the bank.

173.5.8 Project Name: Indian Creek Stabilization

Location: Route AM Howell County

Date: October 2005

Materials Used: Gabion Baskets, 24” Interlocking Concrete Stabilization System, Roll of Geotextile Fabric, Gabion Rock and Shot Rock

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. Purpose of project was to stabilize the creek bank and to correct misalignment of a culvert. A series of concrete armour scour protection units were installed on geotextile material along the base of the creek bank with three weirs being built with gabion baskets. This project required a 404 permit from the COE.

173.5.9 Project Name: Sees Creek Realignment

Location: Route 36 at Route J, Ralls County

Date: 2007

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The headwaters of Sees Creek was relocated due to the construction of two new lanes on Route 36. This project required an individual 404 permit. The relocation was performed by a contractor. Tree planting was performed by incarcerated personnel.

173.6 Seed Mix Formulas

173.6.1 Governing Regulations

CWA Section 402 (Land Disturbance). There are no anticipated DNR issues.

CWA Sections 401 and 404. There are no anticipated Corps of Engineers issues.

173.6.2 Project Name: District 9 Slope and Soil Amendments Mixes

Location: Route 60, Carter County

Date: May 2010

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. This seed mix has been adjusted from the MoDOT slope mix specifications and has proven to perform better on clay acidic soils in the Southest District. (Reference to the final report of the 3-year research project with NRCS). This mix is used by roadside maintenance crews when repairing eroded slopes. The soil amendments that are used include bio stimulate, liquid lime, and ag fertilizer. Bio stimulte is added to improve moisture infiltration, retention, and faster germination. Neutra Lime is a dry product which is applied during seeding to adjust soil pH which aids in the establishment of vegetation.

| Slope Repair Mix V | Rate #/Acre PLS |

|---|---|

| Indiangrass | 9 |

| Little Bluestem | 10 |

| Switchgrass | 8 |

| Annual Ryegrass | 10 |

| Perennial Ryegrass | 5 |

| Red River Crabgrass | 1 |

| Partridge Pea | 2 |

| White Clover | 5 |

| Oats | 20 |

| Coreopsis | .25 |

| Fescue | 10 |

Soil Amendments

Bio stimulate 80 pounds per acre < 1.5% Organic Matter

Liquid Lime 160 pounds per acre < 4.6 pH

Fertilizer 13-13-13 200 pounds per acre

The former District 9 experienced good results in establishing plant growth in harsh soils with this seed mix formula and soil amendments. It is recommended that soil samples are taken to determine pH levels for lime placement. When applying lime and other amendment products on steep terrain, it is recommended that a hydroseeder be utilized.

173.7 Soil Fertility Techniques

173.7.1 Governing Regulations

CWA Section 402 (Land Disturbance). There are no anticipated DNR issues.

CWA Sections 401 and 404. There are no anticipated Corps of Engineers issues.

173.7.2 Project Name: Compost-NRCS Project

Location: Route 60 Carter County, ½ mile east of Route 21 North Junction

Date: May 2007

Materials Used: Compost, Erosion control blanket

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The purpose of the project was to experiment with the use of compost. Soils in the former District 9 have a very low pH and a very low percentage of organic matter. This project tested two methods. The first method applied was a one inch layer of compost that was seeded, fertilized and limed over an erosion control blanket. The second method tested a two-inch layer of compost without an erosion control blanket. During the first growing season there was a very light germination due to the rich and hot compost. After the second season, the slope performed well. After a thorough review it was found that the erosion blanket area functioned the best. The two-inch layer of compost did not hold up to the heavy rains that were received during the first growing season.

173.7.3 Project Name: Compost-Van Buren

Location: Carter County Route 60 and James Street in Van Buren

Date: May 2009

Materials Used: 50 cubic yards of 70% compost and 30% bark mulch, green erosion control blanket, leased bark blower

Contact Information: Paul Denkler, (573) 526-3282

Project Summary. The project was a cooperative effort between MoDOT, Big Springs RC&D, USDA-NRCS-Plant Materials Center and the Van Buren Chamber of Commerce. Soil erosion on the cut slopes of the right of way from a recent expansion of Highway 60 to four lanes had left the area exposed with little vegetation. The project features uses of adapted seeding mixtures, organic mulches, temporary and permanent erosion control blankets, and soil amendments for better seeding establishment and erosion control. Roadside crews used a tracked dozer to repair eroded areas with top soil, areas with little or sparse vegetation a layer of ½ in. to 1 in. compost/bark mulch was applied with a rented bark blower. All areas were hydro seeded with native grass and wildflower seed mixture, in same application liquid lime and fertilizer was applied. After seeding was completed, green dyed erosion control blanket was installed. Permanent erosion blanket was used on a slope drainage ditch.

173.8 References

173.8.1 Additional Regulatory Guidance

Special Section 404 Permitting Scenario--General Permit 41 (GP-41), which is effective until December 31, 2013

If you are in a county that was declared to be a flood disaster county in 2008 and you can show that the maintenance issue is the result of flood damage, then you can use the GP-41 to do the work described below in the “Project Description”. 2008 Flood disaster maps for affected counties can be found at the Federal Emergency Management Agency website. Those activities listed in the “Project Description” do not require pre-construction notification; HOWEVER, THEY DO REQUIRE POST-CONSTRUCTION NOTIFICATION and a signed compliance certification within 60 days of completing the job.

As part of the permitting process, you must contact the Corps of Engineers (COE), submit application materials and submit a mitigation plan prior to completing any flood recovery/repair activity when the repair involves obtaining borrow from forested wetland, borrowing material from potential migratory bird nesting areas, clearing trees along stream channels, working in areas with known exotic species, and/or if the proposed repair activity includes restoration of a stream channel back to the original, preflood location. All other flood repair activities, including all repairs supervised by the Corps of Engineers, pursuant to Public Law 84-99 and/or all repairs supervised by the United States Department of Agriculture, pursuant to the Emergency Watershed Protection Program or to the Emergency Conservation Program can be completed without pre-construction notification to the Corps of Engineers. However, all completed flood repair work, authorized by this permit, must be reported to the Corps of Engineers, Regulatory Branch, within 60 days of completing the project. The report must include the location of the work, asbuilt drawings of the structure(s) and/or fill(s), and a discussion of the avoidance and minimization measures incorporated into the project and mitigation measures employed.

Project Description: To excavate or place fill material for protection and/or repair of existing flood damaged structures, damaged land areas and/or damaged fills as follows:

- a. Repair of levees to existing elevations and cross-section, including breach closures and borrow operations;

- b. Bridge embankment protection (armoring) and/or;

- c. Repair of pre-existing highway or railroad embankments and the addition or repair of stone (armoring) protection;

- d. Repair of pre-existing utility protection structures;

- e. Placement of rock and/or earth materials for stream/ditch bank protection and/or stream/ditch bank restoration;

- f. Drainage channel/ditch restoration to pre-flood capacity and flow line unless the flow line must be altered due to other damage associated with the flood event;

- g. Restoration of creek channels to pre-flooding alignment and capacity;

- h. Construction of temporary roads and temporary fills to facilitate the completion of any of the listed activities.

Note: Maintenance of existing flood damaged structures and/or flood damaged fills, which have been previously authorized, may be authorized by Nationwide Permit No. 3 or exempted by Part 323.4 of Federal regulations 33 CFR 320-331.

173.8.2 Regulatory Conditions for Working in Streams/Wetlands

Relevant Nationwide Permit (NWP) Regional Conditions – Missouri

NWP 13 - Bank Stabilization. Broken concrete used as bank stabilization must be reasonably well graded, consisting of pieces varying in size from 20 pounds up to and including at least 150 pound pieces. Applicants must break all large slabs to conform to the well graded requirement. Generally, the maximum weight of any piece should not be more than 500 pounds. Gravel and dirt should not exceed 15% of the total fill volume. All protruding reinforcement rods, trash, asphalt, and other extraneous materials must be removed from the broken concrete prior to placement in waters of the United States.

NWP 27 - Stream and Wetland Restoration Activities. The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated discharge associated with the relocation of forested wetlands.

NWPs 3 and 14 - Low Water Crossings. The permittee must notify the COE District Engineer when repairing, rehabilitating or replacing low water crossings when discharges of dredged or fill material would raise or lower the lowest elevation of the crossing by a total of 12 in. or more, or when removing the structure. The permittee must propose and employ measures to mitigate the potential impact of impounding gravel above the low water crossing or of releasing impounded-gravel downstream of the structure. Such mitigation might include: removing impounded gravel in the unstable area upstream of the low water crossing to prevent it from being transported downstream and/or constructing a notched weir to slow the release of impounded gravel from upstream of the low water crossing.

Suitable Material (Applicable to all NWPs). In addition to the specific examples in General Condition 6 of the NWPs, the following materials are not suitable for fill activities into waters of the U.S. in conjunction with any NWP: buses or rail cars, construction or demolition debris, garbage, loose or improperly placed tires, treated lumber (chromated copper arsenate (CCA), creosote, and pentachlorophenol), liquid concrete not poured into forms, grouted riprap, bagged cement, and sewage or organic waste.

Culverts. The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated activity which involves the construction of a new or replacement culvert with an inside width/diameter greater than 4 ft. All culverts must be designed to meet the criteria set forth in COE Regional Condition 1, allowing the natural passage of aquatic organisms. See EPG 750.7.3 Environmental Requirements for additional details.

Notification Requirement for Aquatic Resources in Missouri (Applicable To All NWPs). The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated activity which may impact a jurisdictional fen, seep or bog of any size.

Seasonal Restrictions for Activities Proposed in Spawning Areas (Applicable To All NWPs). In addition to the requirements of NWP general condition 3, for any regulated activity, the following specific seasonal restrictions apply. Between the closed dates listed in the Missouri Combined Stream Spawning List, the permittee must not excavate from or discharge into the listed waters. The list of waters with seasonal restrictions is available or on request from the Corps.

Zebra Mussel (Applicable To All NWPs). The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated activity where the applicant is proposing to remove equipment from a known zebra mussel water to use in a different water not known to support zebra mussels. Known zebra mussel waters within Missouri is available on request from the Corps. The notification must include measures to limit the likelihood of spreading the zebra mussel to other waters.

Priority Watersheds (Applicable To All NWPs). The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated activity in a priority watershed. The list of priority watersheds requiring notification is available on request from the Corps.

Lake of the Ozarks. The permittee must notify the COE District Engineer in accordance with the “Notification” general condition of the NWPs (general condition 27) for any regulated activity associated with NWPs 3, 7, 12, 14, 15, 18, 22, 27, 33 and 45. A copy of this notification must also concurrently be sent to AmerenUE. NWPs 2, 13, 16, 19, 25, 29, 31, 35, 36, 39, 41 and 44 are revoked in the Lake of the Ozarks. NWPs 1, 9, 10, 11 and 28 are only valid when both AmerenUE and the Missouri Water Patrol have approved the activity. The Corps and AmerenUE, regardless of the request to use any NWP, may verify the activity under the provisions of Regional General Permit 38M.

Additional information on AmerenUE and Lake of the Ozarks permit requirements is available.

173.8.3 Additional References

EPG 806 Pollution, Erosion and Sediment Control

Highway Slope Maintenance and Slide Restoration Workshop Manual, FHWA December 1988.

Land Disturbance Training, Design & Construction Divisions, 2010.

This category currently contains no pages or media.