Category:303 Rock Base

Contents

303.1 Construction Inspection for Sec 303

303.1.1 Description (Sec 303.1)

When rock is available on a project, often rock base is specified to take advantage of the available material on the project to provide both drainage and structure to the pavement.

303.1.2 Material (Sec 303.2)

Select material (rock/broken concrete) from the rock excavation is used to provide structure and drainage. Too many fines or deleterious material in the rock will prevent the base from draining or will future create future problems for the pavement. Additional mechanical processing such as, scalping, screening, washing, etc. may be necessary to make the material acceptable. The depth of the base limits the maximum size of the rock base. With an 12 in. depth, the maximum size is not to be larger than 9 inches. With an 18 in. depth, the maximum size is not to be larger than 12 in. A thicker lift of rock base is permitted at no additional cost to the commission. The maximum size of rock base of 18 in. can be made for an increased rock base thickness of 24 in. In order to provide a consistent drainable base, the material is to be uniformly graded from course to fine.

303.1.2.1 Visual Acceptance (Sec 303.2.1)

Visual acceptance has not been a problem, except in isolated instances. Our specifications state that the material shall be of durable stone or broken concrete with a 10% limit of earth, sand and non-durable rock material. The maximum size of particle is specified with the base to be uniformly graded from course to fine.

303.1.2.1.1 Too often the source of material is interlaced with extensive clay seams or other undesirable material, which causes the base to be unacceptable as excavated. In these situations, it may be necessary to screen the excessive undesirable material to provide a suitable base.

303.1.2.1.2 If the contractor believes the rejected material meets specification requirements, proving its acceptability rests with the contractor. Acceptance can be demonstrated using the Corps of Engineers test method of excavating a 15 in. X 15 in. area and separating material into its various sizes and components. Flooding the subgrade to demonstrate its drainability has also been used.

303.1.2.1.3 In order to properly seat the various rock sizes into a uniform single layer, rock base is to be bladed or dozed into its final position and compacted in conformance with Sec 203. The inspector must ensure water pockets are not covered. Class C Excavation in rock cuts shall be performed to allow placement of the specified lift thickness. If the contractor uses an optional 24 in. rock base lift, an 18 in. cut and lift is allowable as long as a maximum rock size of 12 in. is maintained for the 18 in. cut.

303.1.3 Construction Requirements (Sec 303.3)

The top 2 in. of the rock base is to constructed with a 2 in. finer rock cap to allow autograding operations. The contractor is allowed a tolerance of 1/2 in. for the finished rock base. The final approved surface of the rock base shall be roughly compensating, i.e. there should be as many cuts in the base to fill in the low areas. The paving contractor may need to provide additional fill aggregate to provide a suitable paving subgrade.

Monitoring is especially crucial if the project is not a turn-key contract, i.e. both base and paving operation are included into a single contract. Large rock in the top layer of the base prevents the paving contractor from autograding the base to obtain a suitable pavement subgrade. Additional operations to remove the larger rock from the subgrade and to reprocess the subgrade not only create additional expense but delay completion of the paving and project completion.

303.1.4 Method of Measurement (Sec 303.4)

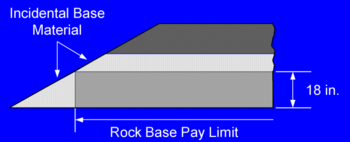

For purposes of design, the volume of rock base is calculated based upon the entire trapezoidal end area. The pay limit however, extends to the point where the surface area, 12 in. or 18 in. thick, intersects the inslope.

During construction, final measurement of the completed rock base will not be made except for authorized changes during construction, or where appreciable errors are found in the contract quantity.

303.1.5 Basis of Payment (Sec 303.5)

Suitable material is often available for rock base from the project rock cuts. If the contractor’s operations render the available project source unusable, the contractor is responsible for any additional expense to provide the necessary base. If the contract indicates suitable rock is available on the project for the rock base but the project source is inadequate, either in quality or quantity, the contractor will be compensated under the provisions of Sec 109.

303.2 Materials Inspection for Sec 303

303.2.1 Scope

To establish procedures for inspection and acceptance of material used in rock base.

303.2.2 Apparatus

Rule with suitable graduations to accurately measure the material to be inspected.

303.2.3 Procedure

The stone or broken concrete is to be visually inspected for quality and size. A number of individual pieces should be measured to determine specification size compliance.

303.2.3.1 Rock base is intended to provide permanent drainage as well as pavement support, therefore, the quality and gradation requirements are very important. The final product must not pond water. Acceptability should be done by a qualified individual, preferably the district geologist.

303.2.3.2 No quantity reports are required, however, a letter from the district geologist to theresident engineer, to the effect that the rock base on the project was observed during placement and meets the standard specifications, is required to be in the project files.

303.3 Laboratory Testing for Sec 303

This guidance establishes procedures for inspection and acceptance of material used in rock base.

303.3.1 Apparatus

Rule with suitable graduations to accurately measure the material to be inspected.

303.3.2 Procedure

The stone or broken concrete is to be visually inspected for quality and size. A number of individual pieces should be measured to determine specification size compliance.

Rock base is intended to provide permanent drainage as well as pavement support, therefore, the quality and gradation requirements are very important. The final product must not pond water. Acceptability should be done by a qualified individual, preferably the district geologist.

No quantity reports are required, however, a letter from the district geologist to the resident engineer, to the effect that the rock base on the project was observed during placement and meets the standard specifications, is required to be in the project files.