Difference between pages "Category:402 Bituminous Surface Leveling" and "Category:170 Maintenance Activity Planning Guidelines"

(updated CLC) |

m (→Index of Printable Planning Guides: update link) |

||

| Line 1: | Line 1: | ||

| − | + | [[image:170.jpg|right|350px]] | |

| − | + | ==Introduction== | |

| + | {|style="padding: 0.3em; margin-right:11px; border:2px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="170px" align="left" | ||

|- | |- | ||

| − | | | + | |[[image:safety begins with me.jpg|165px|center]] |

| − | |||

|- | |- | ||

| − | | | + | |'''Safety Video''' |

| − | |- | + | |- |

| − | + | |[http://www.youtube.com/user/modotvideo Safety is My Story] | |

| − | | | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | |[http://wwwi.dot.missouri/intranet/PotholePatchingSafetyVideo2.wmv Patching Roads] |

|- | |- | ||

| − | | | + | |'''Additional Information''' |

| − | |||

| − | |||

|- | |- | ||

| + | |[http://sharepoint/facilitation/RBM/RM%20Policies/Current%20Policies/Lifting%20Policy.pdf Safe Lifting] | ||

|} | |} | ||

| + | The original Maintenance Planning Guide was developed and published in 1989. The purpose of that manual was to provide maintenance managers with a quick reference for performing most maintenance functions. It included scheduling forms, traffic control guidelines, function codes, commodity codes and a sample crew report. Since the original publication the guide has been updated to meet the needs of MoDOT. | ||

| − | + | This article provides each manager with a list of recommended equipment and materials to use for each function as well as a recommended procedure for that function. The guidelines also have safety reminders and schedules to help managers plan for the best time of year to perform each function. | |

| − | + | This article is intended to be an accurate source of information and a tool that maintenance managers will use to better organize, plan and be more productive leaders. | |

| − | |||

| − | + | <center>'''GENERAL NOTES'''</center> | |

| − | + | Reference the [https://www.modot.org/missouri-standard-plans-highway-construction Missouri Standard Plans] and [https://www.modot.org/missouri-standard-specifications-highway-construction Missouri Standard Specifications for Highway Construction] for performance details on many of the maintenance function planning guidelines. It is the intent of the department to provide as good of a finished product with Maintenance forces as it does by contract methods. | |

| − | + | Recommended materials: When purchasing recommended material, refer to guidance for [[:Category:1100 MAINTENANCE MATERIALS|maintenance materials]]. Guidance for these materials also refers to the [https://www.modot.org/general-services-specifications-mgs-subject Current General Services Specifications (MGS) by Subject] for each of the various maintenance materials. | |

| − | : | ||

| − | |||

| − | |||

| − | + | The Highway Maintenance Tables in the appendix were provided to MoDOT through the Local Technical Assistance Program of the Michigan Tech Transportation Institute at Michigan Technological University in Houghton, Michigan. | |

| − | + | ==Rainy Day Activities== | |

| + | {|style="padding: 0.3em; margin-left:15px; border:1px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="160px" align="right" | ||

| + | |- | ||

| + | |'''Printable Version''' | ||

| + | |- | ||

| + | |[[Media:170.1 Rainy Day Activities.pdf|Rainy Day Activities]] | ||

| + | |} | ||

| − | * | + | *Check roadway surface drainage |

| + | *Check bridge surface for ponding | ||

| + | *Check bridges and box culverts for drift and erosion | ||

| + | *Flush bridge decks | ||

| + | *Check culverts and culvert pipes | ||

| + | *Check drain basins on bridges | ||

| + | *Check high water locations | ||

| + | *Check, clean and repair equipment | ||

| + | *Clean and repair buildings and grounds | ||

| + | *Blade driveways, entrances, shoulders and mailbox turnouts | ||

| + | *Check signs | ||

| + | *Work on special projects | ||

| + | *Clean abutment caps on bridges | ||

| + | *Cut and treat brush and vines under bridges | ||

| + | *Conduct equipment and safety trainings | ||

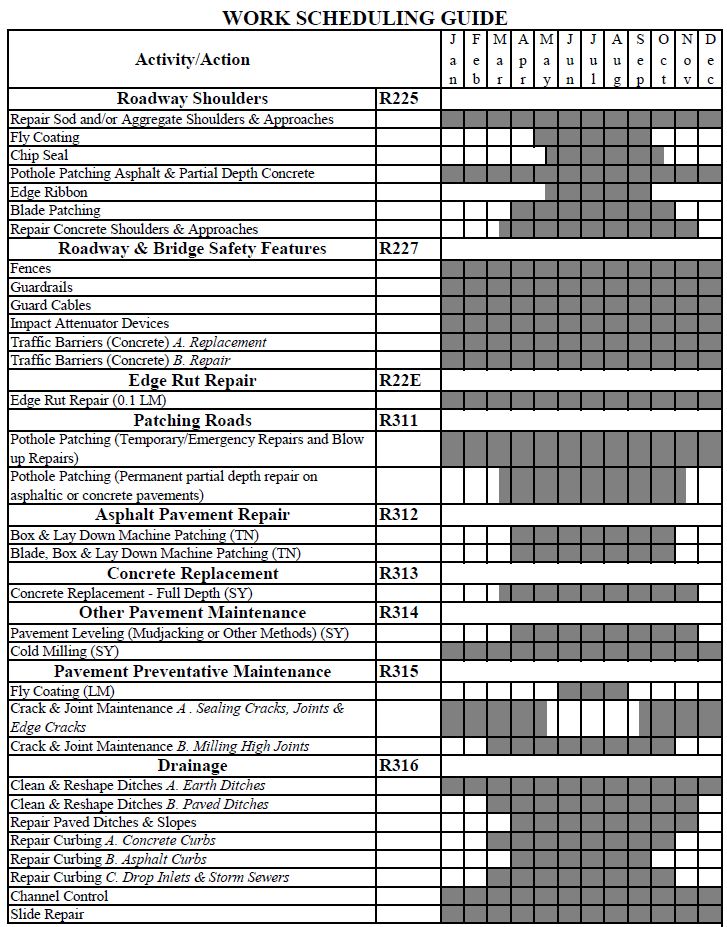

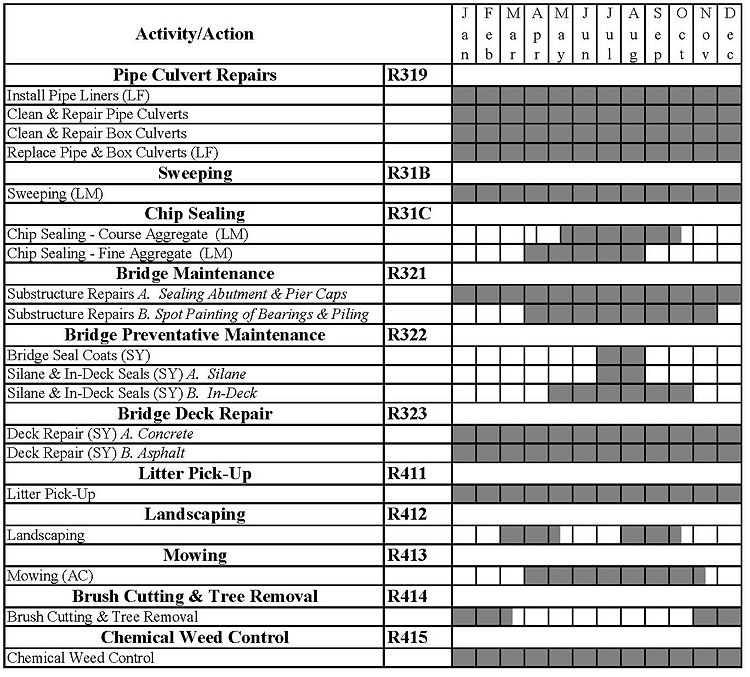

| − | + | ==Work Scheduling Guidelines== | |

| + | {|style="padding: 0.3em; margin-left:10px; border:2px solid #a9a9a9; text-align:center; font-size: 95%; background:#f5f5f5" width="160px" align="right" | ||

| + | |- | ||

| + | |'''Printable Version''' | ||

| + | |- | ||

| + | |[[media:170 Work Scheduling Guide 2014 Dec.xls|Work Scheduling Guide]] | ||

| + | |} | ||

| − | + | :::[[Image:Work schedule1 Dec 2014.jpg|750px]] | |

| + | :::[[Image:Work schedule2 Dec 20143.jpg|750px]] | ||

| − | === | + | ==Index of Printable Planning Guides== |

| − | + | {| border="1" class="wikitable" | |

| − | + | ! colspan="2" style="background:#BEBEBE" | '''Printable Versions of Maintenance Planning Guides''' | |

| − | < | + | |- |

| − | + | ! style="background:#FFFFCC"|'''Activity Code''' !! style="background:#FFFFCC"|'''Action''' | |

| − | | | + | |- |

| − | + | |rowspan="7" | '''R225 Roadway Shoulders'''<br/>(Also see [[:Category:Shoulder Maintenance|Shoulder Maintenance]] and [[771.3 Shaving Shoulder and Around Guardrail|Shaving Shoulder and Around Guardrail]]) || [https://epg.modot.org/forms/general_files/MT/R225_update-blade_patching.pdf Blade Patching] | |

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R225_seal_coat.pdf Seal Coat] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R225_update-edge_ribbon.pdf Edge Ribbon] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R225_update-fly_coating.pdf Fly Coating] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R225_update-pothole_patching_asphalt_and_partial_depth_concrete.pdf Pothole Patching Asphalt & Partial Depth Concrete] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R225_update-Repair_concrete_shoulder_and_approaches.pdf Repair Concrete Shoulders & Approaches] | ||

| + | |- | ||

| + | |[https://epg.modot.org/forms/general_files/MT/R225_update-Repair_sod_aggregate_shoulder_and_approaches.pdf Repair Sod and/or Aggregate Shoulders & Approaches] | ||

| + | |- | ||

| + | | '''R226 Rumble Strips''' (See [[:Category:626 Rumble Strips|Rumble Strips]]) || <div id="R227 Roadway & Bridge Safety Features"></div> No printable guideline available at this time. | ||

| + | |- | ||

| + | | rowspan="7" | '''R227 Roadway & Bridge Safety Features''' || [https://epg.modot.org/forms/general_files/MT/R227_update-fences.pdf Fences] (Also see [[:Category:607 Fencing|Fencing]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R227_update-guardrails.pdf Guardrails] (Also see [[:Category:606 Guardrail and Guard Cable|Guardrail and Guard Cable]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R227_update-guard_cables.pdf Guard Cables] (Also see [[:Category:606 Guardrail and Guard Cable|Guardrail and Guard Cable]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R227_update-impact_attenuator_devices.pdf Impact Attenuator Devices] (Also see [[:Category:612 Impact Attenuators|Impact Attenuators]]) | ||

| + | |- | ||

| + | | '''Traffic Barriers (Concrete)''' (Also see [[:Category:617 Traffic Barrier|Traffic Barrier]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R227_update-traffic_barrier-concrete-replacement.pdf A. Replacement] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R227_update-traffic_barrier-concrete-repair.pdf B. Repair] | ||

| + | |- | ||

| + | | '''R22E Edge Rut Repair (0.1 LM)''' || [https://epg.modot.org/forms/general_files/MT/R22E_update.pdf Edge Rut Repair (0.1 LM)] (Also see [[:Category:Shoulder Maintenance|Shoulder Maintenance]]) | ||

| + | |- | ||

| + | | rowspan="2" | '''R311 Patching Roads'''<br/>(Also see [[:Category:470 Bituminous Asphalt Maintenance|Bituminous Asphalt Maintenance]]) || <div id="R311 Patching Roads"></div> [https://epg.modot.org/forms/general_files/MT/R311_update-pothole_patching-temporary_emergency_repairs_and_blow_up_repairs.pdf Pothole Patching (Temporary/Emergency Repairs and Blow Up Repairs)] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R311_update-pothole_patching-permanent_partial_depth_repair_on_apshaltic_or_concrete_pavement.pdf Pothole Patching (Permanent partial depth repair on asphaltic or concrete pavements)] | ||

| + | |- | ||

| + | | Rowspan="2" | '''R312 Asphalt Pavement Repair (TN)''' || <div id="R312 Asphalt Pavement Repair (TN)"></div> [https://epg.modot.org/forms/general_files/MT/R312_update-Major-box_and_lay_down_machine_patching.pdf Blade, Box & Lay Down Machine Patching (TN)] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R312_update-Major-box_and_lay_down_machine_patching.pdf Box & Lay Down Machine Patching (TN)] | ||

| + | |- | ||

| + | | '''R313 Concrete Replacement (SY)''' || <div id="R313 Concrete Replacement (SY)"></div> [https://epg.modot.org/forms/general_files/MT/R313_update-concrete_replacement_full_depth.pdf Concrete Replacement Full Depth (SY)]<br/>Also See [[:Category:613 Pavement Repair|Pavement Repair]] | ||

| + | |- | ||

| + | | rowspan="2" | '''R314 Other Pavement Maintenance''' || <div id="R314 Other Pavement Maintenance"></div>[https://epg.modot.org/forms/general_files/MT/R314_update-pavement_leveling-mudjacking_or_other_methods.pdf Pavement Leveling (Mudjacking or Other Methods)(SY)] (Also See [[:Category:625 Slab Stabilization|Slab Stabilization]], [[570.5 Mudjacking (Slab Jacking) by MoDOT Maintenance|Mudjacking (Slab Jacking) by MoDOT Maintenance]] and [[771.1 Mud Jacking Bridge Approach|Mud Jacking Bridge Approach]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R314_update-cold_milling.pdf Cold Milling (SY)] (Also See [[:Category:622 Pavement and Bridge Surface Removal and Texturing|Pavement and Bridge Surface Removal and Texturing]]) | ||

| + | |- | ||

| + | | rowspan="5" | '''[https://epg.modot.org/forms/general_files/MT/R315_update-pavement_preventative_maintenace.pdf R315 Pavement Preventative Maintenance (LM)]''' || <div id="R315 Pavement Preventative Maintenance (LM)"></div> '''Crack & Joint Maintenance''' | ||

| + | |- | ||

| + | | A. Fly Coating (LM) (Also See [[413.9 Fly Coating|Fly Coating]]) | ||

| + | |- | ||

| + | | B. Sealing Cracks, Joints & Edge Cracks (Also See [[413.5 Crack Treatment in Bituminous Pavements|Crack Treatment in Bituminous Pavements]] and [[570.2 Joint and Crack Maintenance|Joint and Crack Maintenance]]) | ||

| + | |- | ||

| + | | C. Milling High Joints (Also See [[:Category:622 Pavement and Bridge Surface Removal and Texturing|Pavement and Bridge Surface Removal and Texturing]]) | ||

| + | |- | ||

| + | | D. Scrub Seals (LM) | ||

| + | |- | ||

| + | | rowspan="10" | '''R316 Drainage''' || <div id="R316 Drainage"></div> '''Clean & Reshape Ditches''' | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-earth_ditches.pdf A. Earth Ditches] (Also See [[:Category:773 Pipe, Box Culvert and Miscellaneous Drainage Maintenance|Pipe, Box Culvert and Miscellaneous Drainage Maintenance]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-paved_ditches.pdf B. Paved Ditches] (Also See [[:Category:609 Paved Drainage|Paved Drainage]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-repair_paved_ditches_and_slopes.pdf Repair Paved Ditches & Slopes] (Also See [[:Category:609 Paved Drainage|Paved Drainage]]) | ||

| + | |- | ||

| + | | '''Repair Curbing''' | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-repair_curbing-concrete_curbs.pdf A. Concrete Curbs] (Also See [[:Category:609 Paved Drainage|Paved Drainage]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-repair_curbing-asphalt_curbs B. Asphalt Curbs] (Also See [[:Category:609 Paved Drainage|Paved Drainage]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-clean_and_reshape_ditches-repair_curbing-drop_inlets_and_storm_sewers.pdf C. Drop Inlets & Storm Sewers] (Also See [[:Category:614 Drainage Fittings (Grate Inlets)|Drainage Fittings (Grate Inlets)]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-channel_control.pdf Channel Control] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R316_update-slide_repair.pdf Slide Repair] | ||

| + | |- | ||

| + | | rowspan="5" | '''R319 Pipe Culvert Repairs (LF)''' || <div id="R319 Pipe Culvert Repairs (LF)"></div> '''Clean & Repair Pipe & Box Culverts''' | ||

| + | |- | ||

| + | |[https://epg.modot.org/forms/general_files/MT/R319_update-install_pipe_liners.pdf Install Pipe Liners (LF)] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R319_update-clean_and_repair_pipe_culverts.pdf Pipe Culverts] (Also See [[:Category:773 Pipe, Box Culvert and Miscellaneous Drainage Maintenance|Pipe, Box Culvert and Miscellaneous Drainage Maintenance]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R319_update-clean_and_repair_box_culverts.pdf Box Culverts] (Also See [[:Category:773 Pipe, Box Culvert and Miscellaneous Drainage Maintenance|Pipe, Box Culvert and Miscellaneous Drainage Maintenance]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R319_update-replace_pipe_and_box_culverts.pdf Replace Pipe & Box Culverts (LF)] (Also See [[:Category:773 Pipe, Box Culvert and Miscellaneous Drainage Maintenance|Pipe, Box Culvert and Miscellaneous Drainage Maintenance]]) | ||

| + | |- | ||

| + | | '''R31B Sweeping (LM)''' || [https://epg.modot.org/forms/general_files/MT/R31B_update-sweeping.pdf Sweeping (LM)] (For routine flushing of bridge decks see [[771.2 Bridge Cleaning and Flushing|Bridge Cleaning and Flushing]]) | ||

| + | |- | ||

| + | | rowspan="3" | '''R31C Seal Coating (LM)''' || '''Seal Coating''' | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R31C_Seal_Coat-Course_Aggregate.pdf A. Course Aggregate] (Also See [[:Category:409 Seal Coat|Seal Coat]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R31C_Seal_Coat-Fine_Aggregate.pdf B. Fine Aggregate] (Also See [[413.6 Scrub Seal Treatment|Scrub Seal Treatment]]) | ||

| + | |- | ||

| + | | rowspan="3" | '''R321 Bridge Maintenance''' (Also See R322 Bridge Preventative Maintenance and R327 Other Bridge Preventative Maintenance) || '''Substructure Repairs''' (Also See [[:Category:774 Cathodic Protection|Cathodic Protection]], [[770.7 Maintenance of Bridge Superstructure|Superstructure Maintenance]] and [[770.8 Maintenance of Bridge Substructure|Substructure Maintenance]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R321_update-substructure_repairs-sealing_abutment_and_pier_caps.pdf A. Sealing Abutment & Pier Caps] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R321_update-substructure_repairs-spot_painting_of_bearings_and_piling.pdf B. Spot Painting of Bearings & Piling] | ||

| + | |- | ||

| + | | rowspan="4" | '''R322 Bridge Preventative Maintenance''' || <div id="R322 Bridge Preventative Maintenance"></div>[https://epg.modot.org/forms/general_files/MT/R322_update-bridge_seal_coats.pdf Bridge Seal Coats (SY)] (Also See [[771.15 Chip Seal to Entire Deck|Seal Coat to Entire Deck]]) | ||

| + | |- | ||

| + | | '''Silane & In-Deck Seals (SY)''' | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R322_update-silane_and_in-deck_seal-silane.pdf A. Silane] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R322_update-silane_and_in-deck_seals-in-deck.pdf B. In-Deck] (Also See [[771.17 Concrete Crack Filler - Low Viscosity Polymer (LVP)|Concrete Crack Filler -Low Viscosity Polymer (LVP)]]) | ||

| + | |- | ||

| + | | rowspan="3" | '''R323 Bridge Deck Repair (SY)''' || '''Deck Repair (SY)''' (Also See [[771.9 Temporary Bridge Deck Repair|Temporary Bridge Deck Repair]]) | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R323_update-deck_repair-concrete.pdf A. Concrete] | ||

| + | |- | ||

| + | | [https://epg.modot.org/forms/general_files/MT/R323_update-deck_repair-asphalt.pdf B. Asphalt] | ||

| + | |- | ||

| + | | '''R324 Bridge Painting (TN)''' || No printable guideline available at this time. | ||

| + | |- | ||

| + | | rowspan="9" | '''R327 Other Bridge Preventative Maintenance''' || No printable guidelines available at this time. See the following: | ||

| + | |- | ||

| + | | [[771.4 Drain Basin Maintenance | Drain Basin Maintenance]] | ||

| + | |- | ||

| + | | [[771.5 Mat Gutter Maintenance | Mat Gutter Maintenance]] | ||

| + | |- | ||

| + | | [[771.6 Channel Work - Gabion Installation | Channel Work - Gabion Installation]] | ||

| + | |- | ||

| + | | [[771.7 Channel Work - Rock Blanket | Channel Work - Rock Blanket]] | ||

| + | |- | ||

| + | | [[771.8 Remove Drift | Remove Drift]] | ||

|- | |- | ||

| − | | | + | | [[771.13 Sealing Abutment and Pier Caps | Sealing Abutment and Pier Caps]] |

|- | |- | ||

| − | | | + | | [[771.14 Spot Painting of Bearings and Piling | Spot Painting of Bearings and Piling]] |

|- | |- | ||

| − | | | + | | [[771.16 Bridge Deck Crack Pouring | Bridge Deck Crack Pouring]] |

|- | |- | ||

| − | | | + | | rowspan="4" | '''R328 Bridge Joint Maintenance''' || No printable guidelines available at this time. See the following: |

|- | |- | ||

| − | | | + | | [[771.10 Bridge Joint Sealing - Hot Pour | Bridge Joint Sealing - Hot Pour]] |

|- | |- | ||

| − | | | + | | [[771.11 Bridge Joint Sealing - Silicone | Bridge Joint Sealing - Silicone]] |

|- | |- | ||

| − | | | + | | [[771.12 Bridge Joint Sealing - Polytite | Bridge Joint Sealing - Polytite]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | rowspan="2" | '''R329 Bridge Cleaning & Flushing''' || No printable guidelines available at this time. See the following: |

|- | |- | ||

| − | | | + | | [[771.2 Bridge Cleaning and Flushing | Bridge Cleaning and Flushing]] |

|- | |- | ||

| − | | | + | | '''R411 Litter Pick-Up''' || <div id="R411 Litter Pick-Up"></div> [https://epg.modot.org/forms/general_files/MT/R411_update-litter_pick_up.pdf Litter Pick-Up] (Also See [[:Category:824 Adopt-A-Highway and Sponsor-A-Highway Programs|Adopt-A-Highway and Sponsor-A-Highway Programs]]) |

|- | |- | ||

| − | | | + | | '''R412 Landscaping''' || <div id="R412 Landscaping"></div> [https://epg.modot.org/forms/general_files/MT/R412_update-general_plant_installation_and_fertilizing_seeding_and_mulching.pdf Fertilizing, Seeding & Mulching] (Also See [[:Category:800 ROADSIDE DEVELOPMENT|Roadside Development]]) |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | See [[ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | + | | '''R413 Mowing (AC)''' || <div id="R413 Mowing (AC)"></div> [https://epg.modot.org/forms/general_files/MT/R413_update-mowing.pdf Mowing (AC)]] (Also See [[:Category:822 Roadside Vegetation Management|Roadside Vegetation Management]]) | |

|- | |- | ||

| − | | | + | | '''R414 Brush Cutting & Tree Removal''' || <div id="R414 Brush Cutting & Tree Removal"></div> [https://epg.modot.org/forms/general_files/MT/R414_update-brush_cutting_and_tree_removal.pdf Brush Cutting & Tree Removal] (Also See [[:Category:822 Roadside Vegetation Management|Roadside Vegetation Management]]) |

|- | |- | ||

| − | | | + | | '''R415 Chemical Weed Control''' || <div id="R415 Chemical Weed Control"></div> [https://epg.modot.org/forms/general_files/MT/R415_update-chemical_weed_control.pdf Chemical Weed Control] (Also See [[:Category:821 Herbicides and Roadsides|Herbicides and Roadsides]]) |

|} | |} | ||

| − | + | ==[[Media:Highway Maintenance Tables and Conversion Factors.pdf|Highway Maintenance Tables and Conversion Factors]]== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | : | + | The [[Media:Highway Maintenance Tables and Conversion Factors.pdf|Highway Maintenance Tables and Conversion Factors]] contain helpful tables and conversion factors that aid in volumetric and weight measurements needed in maintenance activities. |

Revision as of 14:01, 30 May 2024

Contents

Introduction

| Safety Video |

| Safety is My Story |

| Patching Roads |

| Additional Information |

| Safe Lifting |

The original Maintenance Planning Guide was developed and published in 1989. The purpose of that manual was to provide maintenance managers with a quick reference for performing most maintenance functions. It included scheduling forms, traffic control guidelines, function codes, commodity codes and a sample crew report. Since the original publication the guide has been updated to meet the needs of MoDOT.

This article provides each manager with a list of recommended equipment and materials to use for each function as well as a recommended procedure for that function. The guidelines also have safety reminders and schedules to help managers plan for the best time of year to perform each function.

This article is intended to be an accurate source of information and a tool that maintenance managers will use to better organize, plan and be more productive leaders.

Reference the Missouri Standard Plans and Missouri Standard Specifications for Highway Construction for performance details on many of the maintenance function planning guidelines. It is the intent of the department to provide as good of a finished product with Maintenance forces as it does by contract methods.

Recommended materials: When purchasing recommended material, refer to guidance for maintenance materials. Guidance for these materials also refers to the Current General Services Specifications (MGS) by Subject for each of the various maintenance materials.

The Highway Maintenance Tables in the appendix were provided to MoDOT through the Local Technical Assistance Program of the Michigan Tech Transportation Institute at Michigan Technological University in Houghton, Michigan.

Rainy Day Activities

| Printable Version |

| Rainy Day Activities |

- Check roadway surface drainage

- Check bridge surface for ponding

- Check bridges and box culverts for drift and erosion

- Flush bridge decks

- Check culverts and culvert pipes

- Check drain basins on bridges

- Check high water locations

- Check, clean and repair equipment

- Clean and repair buildings and grounds

- Blade driveways, entrances, shoulders and mailbox turnouts

- Check signs

- Work on special projects

- Clean abutment caps on bridges

- Cut and treat brush and vines under bridges

- Conduct equipment and safety trainings

Work Scheduling Guidelines

| Printable Version |

| Work Scheduling Guide |

Index of Printable Planning Guides

Highway Maintenance Tables and Conversion Factors

The Highway Maintenance Tables and Conversion Factors contain helpful tables and conversion factors that aid in volumetric and weight measurements needed in maintenance activities.

This category currently contains no pages or media.