Difference between revisions of "751.40 LFD Widening and Repair"

m (Per BR, numerous minor clarifications related to barrier pay items) |

|||

| (29 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | <div style="float: right; width: 500px; margin-top: 5px; margin-left: 30px; margin-bottom: 30px;">__TOC__</div> | ||

| + | |||

== 751.40.1 General == | == 751.40.1 General == | ||

| − | |||

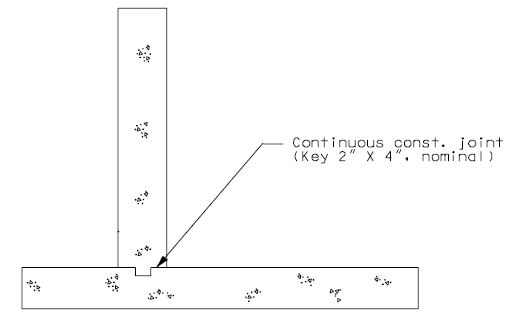

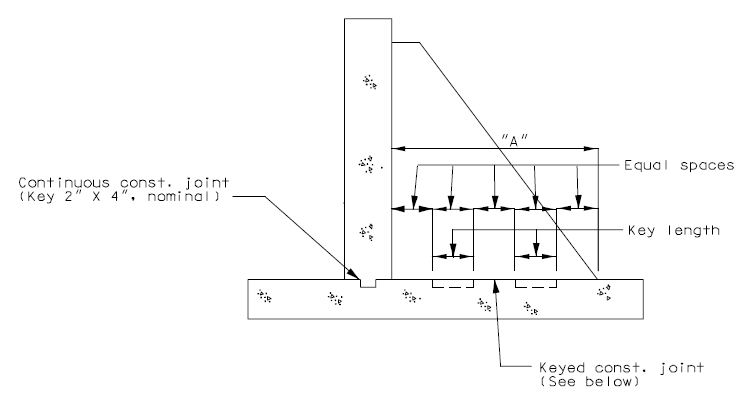

=== 751.40.1.1 Widening and Repair of Existing Structures === | === 751.40.1.1 Widening and Repair of Existing Structures === | ||

The Federal Highway Administration and the States have established a goal that the LRFD standards be used on all new bridge designs after October 2007. For modification to existing structures and with the approval of the Structural Project Manager or Structural Liaison Engineer, the LRFD Specifications or the specifications which were used for the original design, may be used by the designer. | The Federal Highway Administration and the States have established a goal that the LRFD standards be used on all new bridge designs after October 2007. For modification to existing structures and with the approval of the Structural Project Manager or Structural Liaison Engineer, the LRFD Specifications or the specifications which were used for the original design, may be used by the designer. | ||

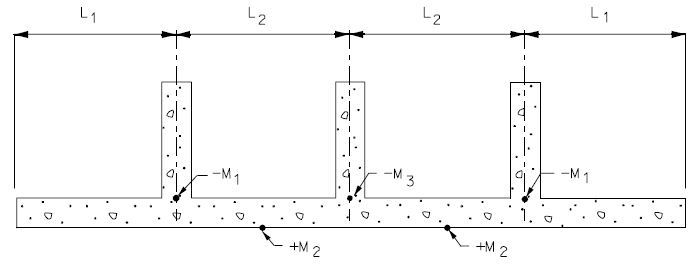

| − | + | ==751.40.2 Deck Treatments== | |

| − | + | ===751.40.2.1 Resurfacing=== | |

| − | |||

| − | |||

| − | |||

| − | {| | + | {| style="text-align: center; margin: 0 auto;" |

|- | |- | ||

| − | + | | [[Image:751.40_Resurfacing_Section_Thru_Roadway.gif|center]] | |

|- | |- | ||

| − | | | + | | <big>'''PLAN'''</big> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| − | |||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| − | + | |- | |

| − | + | | [[Image:751.40_Resurfacing_Plan.gif|center]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | {| | ||

| − | | | ||

| − | | | ||

|- | |- | ||

| − | | | + | | <big>'''SECTION THRU ROADWAY'''</big> |

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Place the following notes on plans. | Place the following notes on plans. | ||

| − | :The existing | + | : The existing asphaltic concrete surface shall be removed to a uniform grade line * below the existing control grade line as noted. |

| − | + | : Resurface with * Asphaltic Concrete. | |

| − | :Resurface with | + | : <nowiki>*</nowiki> Depth of asphaltic concrete as specified in the Bridge Memorandum. |

| − | |||

| − | : | ||

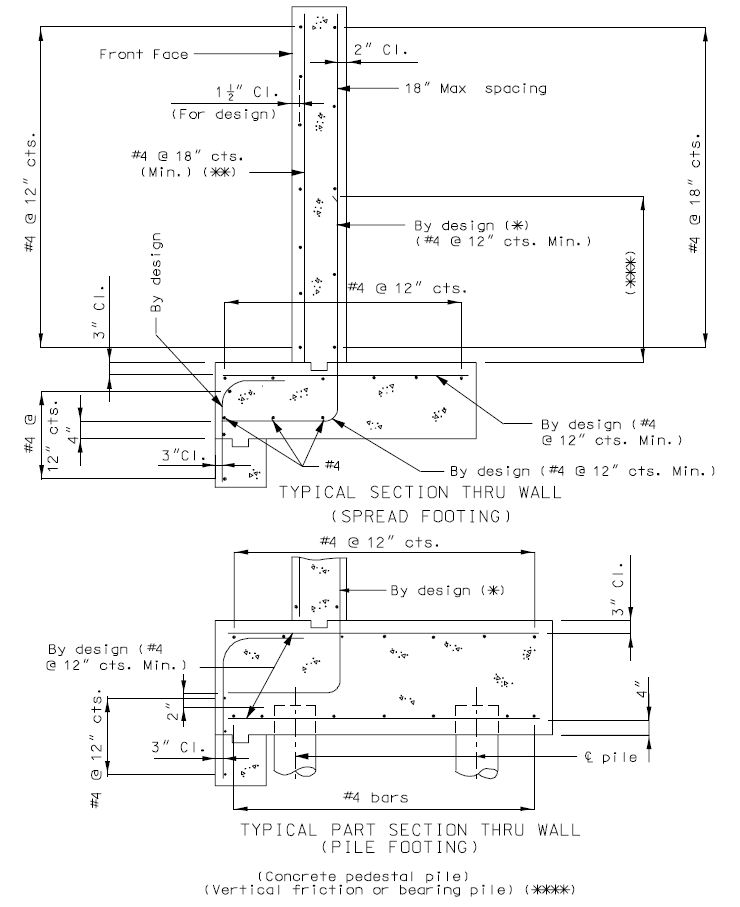

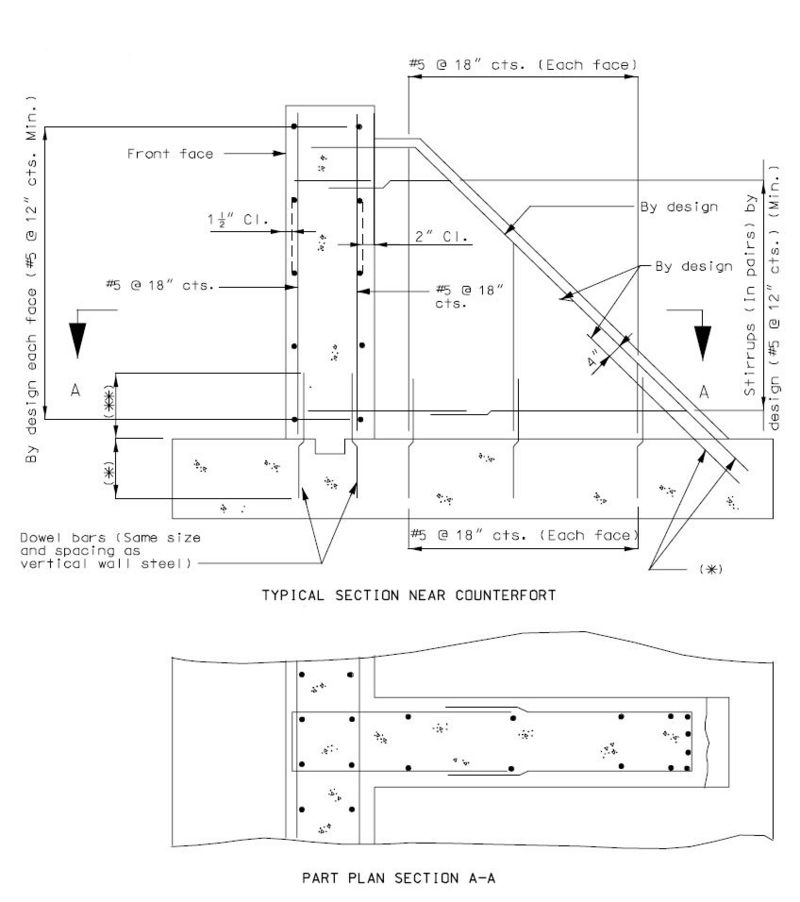

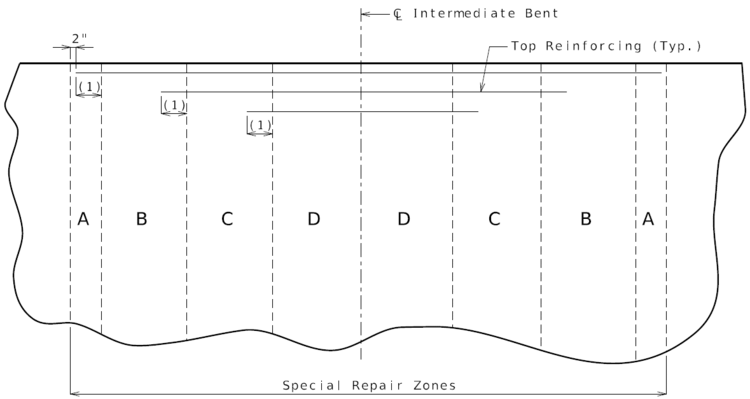

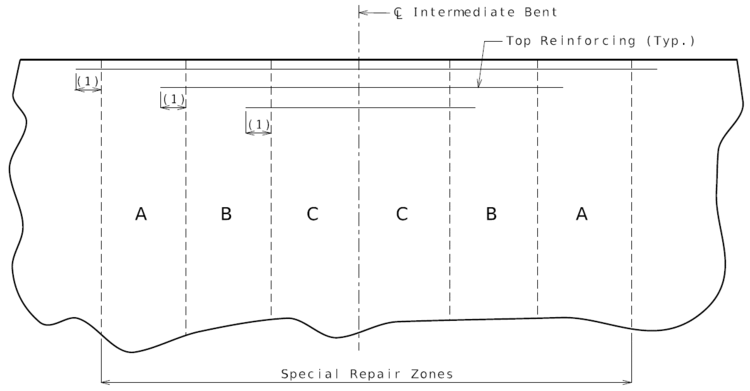

===751.40.2.2 Special Repair Zones=== | ===751.40.2.2 Special Repair Zones=== | ||

| Line 93: | Line 41: | ||

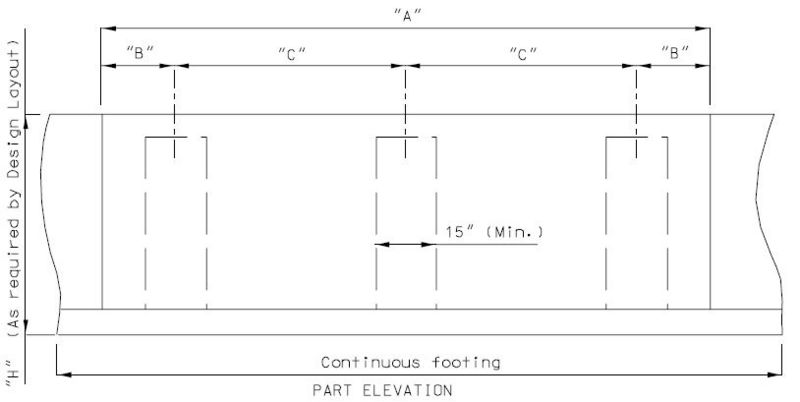

Note: | Note: | ||

| − | :- Case 1 shall not be used for polyester polymer and low slump concrete wearing surfaces (too stiff for monolithic repairs). | + | :- Case 1 shall not be used for polyester polymer and low slump concrete wearing surfaces (too stiff for monolithic repairs). |

| − | :- Conventional deck repair is required with void tube replacement after hydro demolition with both Case 1 and Case 2. | + | :- Conventional deck repair is required with void tube replacement after hydro demolition with both Case 1 and Case 2. |

| − | :- If an excessive number of zones are required at any bent, see the Structural Project Manager or Structural Liaison Engineer. | + | :- If an excessive number of zones are required at any bent, see the Structural Project Manager or Structural Liaison Engineer. |

| − | :- Consider combining zones if the length of a zone in the longitudinal direction of the bridge is less than 24 inches. | + | :- Consider combining zones if the length of a zone in the longitudinal direction of the bridge is less than 24 inches. |

| − | [[image:751.40.2. | + | |

| − | ::(1) Development Length. | + | {| style="text-align: center; margin: 0 auto;" |

| − | ::See [[751.50_Standard_Detailing_Notes|EPG 751.50 Standard Detailing Notes]] for appropriate notes. | + | |- |

| + | | [[image:751.40.2.2_hydro_part-plan.png|center|750px]] | ||

| + | |- | ||

| + | | <big>'''PART PLAN OF SLAB SHOWING REPAIR ZONES (A, B, C and D)'''</big> | ||

| + | |} | ||

| + | :::(1) Development Length. | ||

| + | :::See [[751.50_Standard_Detailing_Notes|EPG 751.50 Standard Detailing Notes]] for appropriate notes. | ||

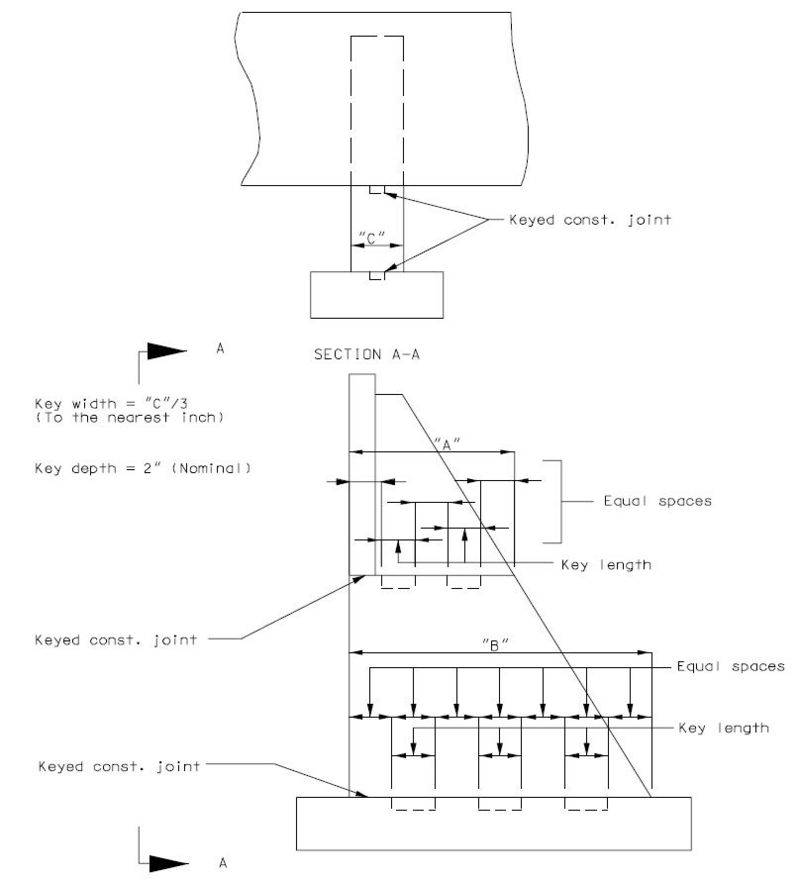

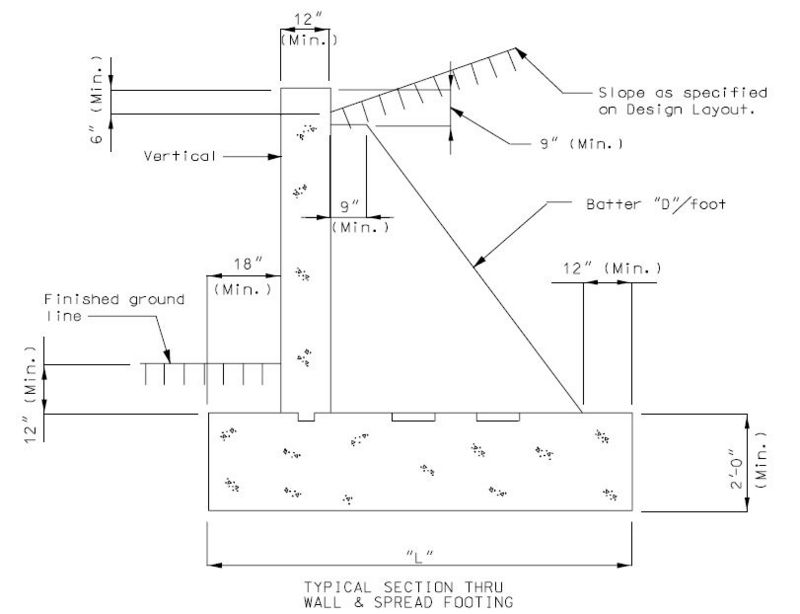

'''Non-Hydro Demolition Projects''' | '''Non-Hydro Demolition Projects''' | ||

| Line 106: | Line 60: | ||

Note: | Note: | ||

| − | :- If an excessive number of zones are required at any bent, see the Structural Project Manager or Structural Liaison Engineer. | + | :- If an excessive number of zones are required at any bent, see the Structural Project Manager or Structural Liaison Engineer. |

| − | :- Consider combining zones if the length of a zone in the longitudinal direction of the bridge is less than 24 inches | + | :- Consider combining zones if the length of a zone in the longitudinal direction of the bridge is less than 24 inches. |

| − | |||

| − | |||

| − | |||

| − | = | + | {| style="text-align: center; margin: 0 auto;" |

| + | |- | ||

| + | | [[image:751.40.2.2_nonhydro_part-plan.png|center|750px]] | ||

| + | |- | ||

| + | | <big>'''PART PLAN OF SLAB SHOWING REPAIR ZONES (A, B and C)'''</big> | ||

| + | |} | ||

| + | :::(1) Development Length. | ||

| + | :::See [[751.50_Standard_Detailing_Notes|EPG 751.50 Standard Detailing Notes]] for appropriate notes. | ||

| − | + | ===751.40.2.3 Deck Repair and Filled Joints=== | |

| − | |||

| − | |||

| + | <div style="float: right; margin-top: 5px; margin-bottom: 5px; padding: 5px; text-align:center; border: 1px solid black; border-radius:5px; box-shadow:5px 5px 5px #888888"> | ||

| + | '''Bridge Deck, Repair'''</br> | ||

| + | [https://spexternal.modot.mo.gov/sites/cm/CORDT/RDT02002.pdf Report 2002]</br> | ||

| + | '''See also:''' [https://www.modot.org/research-publications Research Publications] | ||

| + | </div> | ||

| − | + | {| border="1" class="wikitable" style="margin: 0 auto; text-align: center" | |

| − | + | |+ | |

| − | + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | {| border="1" class="wikitable" style="margin: | ||

| − | |+ | ||

| − | | style="background:#BEBEBE | ||

|- | |- | ||

| − | | | + | | Rehabilitation, Surfacing & Widening – RHB; Deck Rehab (Deck Repair and Wearing Surface Details) |

|} | |} | ||

| − | |||

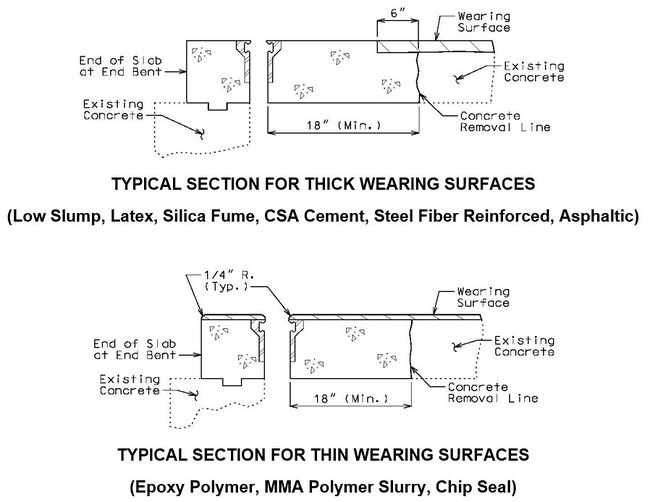

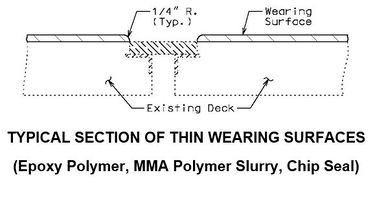

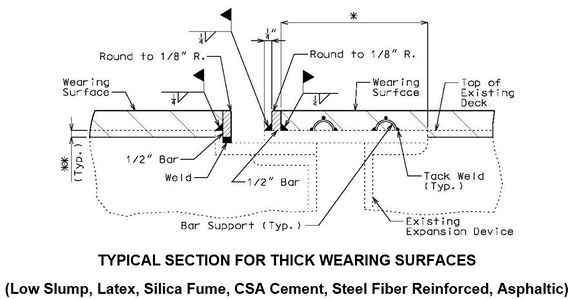

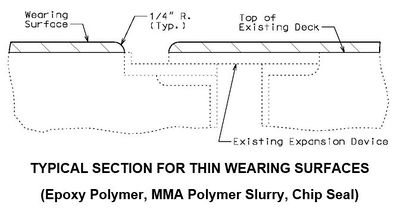

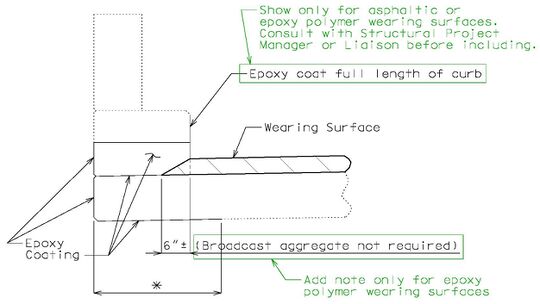

| + | ===751.40.2.4 Wearing Surfaces=== | ||

| − | + | '''Replacement of Typical Expansion Joint Systems (Strip Seal Shown, Other Systems Similar)''' | |

| − | + | [[image:751.40.3.1 wearing surfaces.jpg|center|650px]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

When concrete is removed and armor is replaced, see [[751.13 Expansion Joint Systems|EPG 751.13 Expansion Joint Systems]] for the appropriate expansion joint system details and [[751.50 Standard Detailing Notes#H5. Expansion Joint Systems|EPG 751.50 H5]] for the appropriate notes. | When concrete is removed and armor is replaced, see [[751.13 Expansion Joint Systems|EPG 751.13 Expansion Joint Systems]] for the appropriate expansion joint system details and [[751.50 Standard Detailing Notes#H5. Expansion Joint Systems|EPG 751.50 H5]] for the appropriate notes. | ||

| Line 191: | Line 100: | ||

When a thick wearing surface (low slump, latex, silica fume, CSA cement, steel fiber reinforced, asphaltic) is used, the elastomeric joint must be replace by another type of expansion joint system. | When a thick wearing surface (low slump, latex, silica fume, CSA cement, steel fiber reinforced, asphaltic) is used, the elastomeric joint must be replace by another type of expansion joint system. | ||

| + | |||

[[image:751.40.3.1 elastomeric.jpg|center|375px]] | [[image:751.40.3.1 elastomeric.jpg|center|375px]] | ||

'''Flat Plate Expansion Joint System ''' | '''Flat Plate Expansion Joint System ''' | ||

| + | |||

[[image:751.40.3.1 flat thick.jpg|center|575px]] | [[image:751.40.3.1 flat thick.jpg|center|575px]] | ||

| − | :: | + | ::: '''*''' When this dimension exceeds 3" and a concrete wearing surface is used, tack weld a one inch bar chair to the plate for each 3" of plate to be covered by the wearing surface. |

| − | :: | + | ::: '''**''' Scarify existing slab. See the Bridge Memorandum for the minimum depth of scarification. Scarification not required for asphaltic concrete wearing surface. |

| + | ::: Note: See standard plans for Steel Dams at Expansion Joints. | ||

| − | |||

| − | |||

[[image:751.40.3.1 flat thin.jpg|center|400px]] | [[image:751.40.3.1 flat thin.jpg|center|400px]] | ||

| + | ===751.40.2.5 Edge Treatments=== | ||

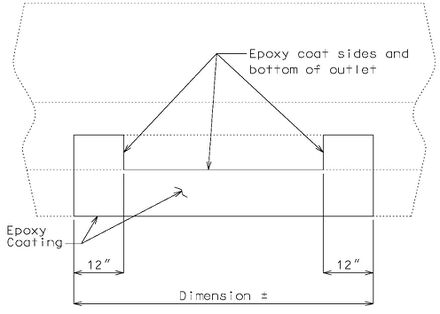

| + | ====751.40.2.5.1 Epoxy Coating==== | ||

| − | ''' | + | {| style="text-align: center; margin: 0 auto;" |

| + | |- | ||

| + | | [[Image:751.40.3.1 latex section.jpg|center|540px]] | ||

| + | |- | ||

| + | | <big>'''TYPICAL SECTION OF EXISTING CURB<br/>OUTLET SHOWING LIMITS OF EPOXY COATING'''</big> | ||

| + | |} | ||

| + | ::: Note: | ||

| + | ::: '''*''' Dimension to edge of girder or stringer ±. For bridges that do not have girders or stringers use 2'-6", except that if with thrie beam rail, then use 4'-0". | ||

| + | ::: Consult with Structural Project Manager or Liaison for making work incidental to another item or use of pay item "Cleaning and Epoxy Coating". | ||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| + | |- | ||

| + | | [[Image:751.40.3.1 latex elevation.jpg|440px]] | ||

| + | |- | ||

| + | | <big>'''TYPICAL ELEVATION OF EXISTING CURB<br/>OUTLET SHOWING LIMITS OF EPOXY COATING'''</big><br/>(Wearing surface not shown for clarity) | ||

| + | |} | ||

| + | ====751.40.2.5.2 Edge Repair==== | ||

| − | + | If slab edge repair is specified on the Bridge Memorandum when the barrier or railing is not removed or when full depth repair is not a pay item, the following detail shall be provided. | |

| + | {| style="text-align: center; margin: 0 auto;" | ||

| + | |- | ||

| + | | [[Image:751.40_Concrete_Wearing_Surface_Slab_Edge_Repair_(Concrete_Edge_Repair)_no_1.gif|center]] | ||

| + | |- | ||

| + | | <big>'''CONCRETE EDGE REPAIR'''</big> | ||

| + | |} | ||

| + | :::If the barrier or railing is removed when full depth repair and slab edge repair are pay items, the following detail shall be provided. | ||

| − | |||

| − | ( | + | {| style="text-align: center; margin: 0 auto;" |

| − | + | |- | |

| − | + | | [[Image:751.40_Concrete_Wearing_Surface_Slab_Edge_Repair_(Concrete_Edge_Repair)_no_1.gif|center]] | |

| + | |- | ||

| + | | <big>'''CONCRETE EDGE REPAIR'''</big> | ||

| + | |} | ||

| + | ::: '''*''' If the dimension exceeds 4 inches, the repair extending to the edge of slab will be paid for as Full Depth Repair. | ||

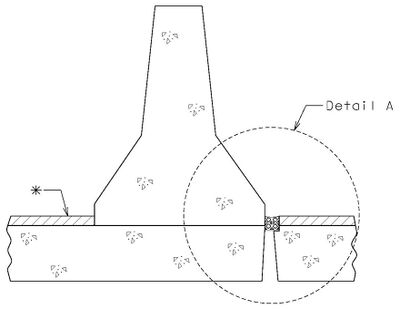

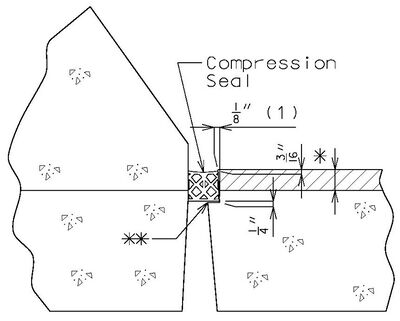

| + | ===751.40.2.6 Longitudinal Joints=== | ||

| + | '''REPLACEMENT OF EXISTING EXPANSION DEVICE''' | ||

| − | + | '''MEDIAN BARRIER ''' | |

| + | {| style="text-align: center; margin: 0 auto;" | ||

| + | |- | ||

| + | | [[Image:751.40.2.6_section_thru_barrier.jpg|center|400px]] | ||

| + | |- | ||

| + | | <big>'''SECTION THRU BARRIER'''</big> | ||

| + | |} | ||

| − | |||

| + | {| style="text-align: center; margin: 0 auto;" | ||

| + | |- | ||

| + | | [[Image:751.40.2.6_detail_A.jpg|center|400px]] | ||

| + | |- | ||

| + | | <big>'''DETAIL A'''</big> | ||

| + | |} | ||

| + | ::: (1) May be cast vertical and saw cut to slant. | ||

| + | ::: * Latex Concrete Wearing Surface = 1-3/4".<br/>Low Slump Concrete Wearing Surface = 2-1/4". | ||

| + | ::: ** Cut minimum 1/2" support notch (rough finish). Remove any existing compression seal. | ||

| + | ===751.40.2.7 Temporary Traffic Control Device=== | ||

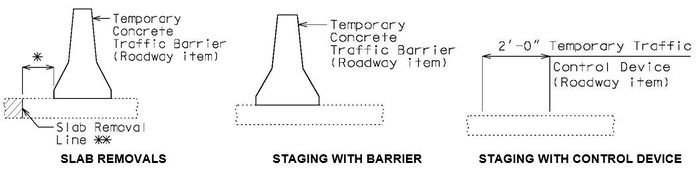

| − | ' | + | Show Barrier as per district recommendation. Typically Barrier is shown when structure is on interstate and/or the rail is being removed. Otherwise, show the dimension lines with 2'-0" dimension. |

| + | [[image:751.40.2.5.jpg|center|700px]] | ||

| − | If | + | ::: '''*''' If this dimension is less than 3 feet, the temporary concrete traffic barrier shall be attached with tie-down straps, with the approval of the Structural Project Manager or Structural Liaison Engineer. Where lateral deflection cannot be tolerated, the temporary concrete traffic barrier shall be attached with the bolt through deck detail (to be used only on existing decks). See [[617.1 Temporary Traffic Barriers|EPG 617.1 Temporary Traffic Barriers]] and [[751.1 Preliminary Design#751.1.2.12 Temporary Barriers|EPG 751.1.2.12 Temporary Barriers]]. |

| + | ::: '''**''' Where slab removal represents small and discontinuous openings in the deck along the bridge length (e.g. expansion device replacement) use of either a flat steel plate, a 22 ½” temporary traffic control device or a temporary concrete traffic barrier may be more appropriate. Consult with the Structural Project Manager or Structural Liaison Engineer. | ||

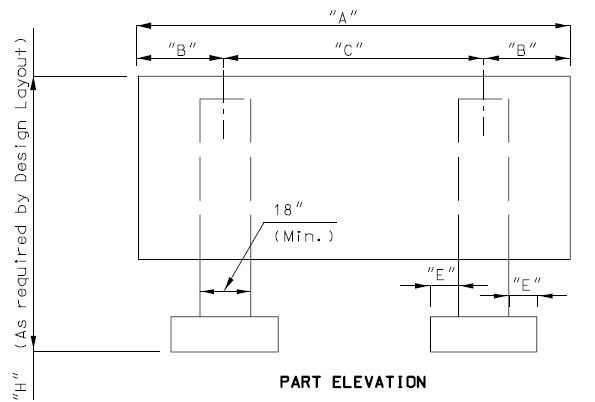

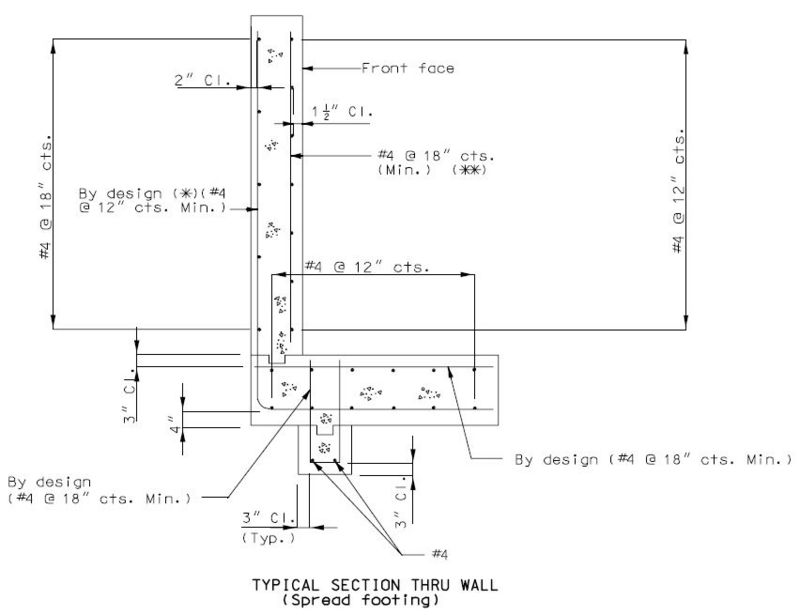

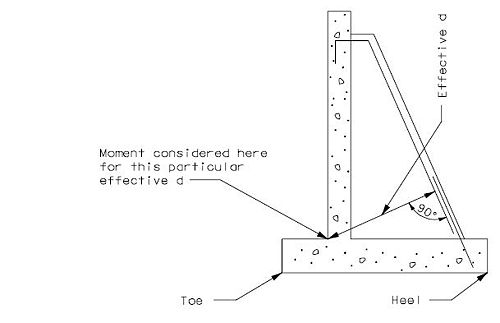

| + | ==751.40.3 Substructure Repair== | ||

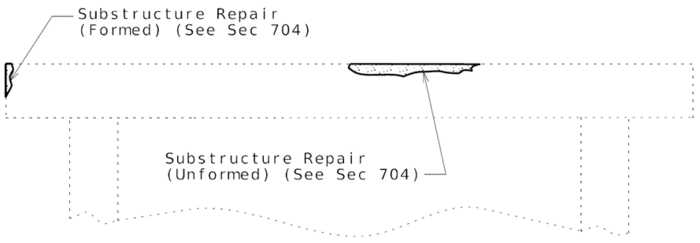

| + | ===751.40.3.1 Formed and Unformed Repair Areas=== | ||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| + | |- | ||

| + | | [[Image:751.40.3.1_elev_int_bent.png|center|700px]] | ||

| + | |- | ||

| + | | <big>'''Elevation of Int. Bent'''</big> | ||

| + | |} | ||

| − | < | + | {| style="text-align: center; margin: 0 auto;" |

| + | |- | ||

| + | | [[Image:751.40.3.1_sec_through_end_bent.png|center|400px]] | ||

| + | |- | ||

| + | | <big>'''Section through End Bent'''</big> | ||

| + | |} | ||

| + | ===751.40.3.2 Bent Cap Shear Strengthening using FRP Wrap=== | ||

| − | + | {| border="1" class="wikitable" style="margin: 0 auto; text-align: center" | |

| + | |+ | ||

| + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | ||

| + | |- | ||

| + | | Rehabilitation, Surfacing & Widening; Fiber Reinf. Polymer (FRP) Wrap for Bent Cap Strengthening [RHB08] | ||

| + | |} | ||

| + | Fiber Reinforced Polymer (FRP) wrap may be used for Bent Cap Shear Strengthening. | ||

| − | + | '''When to strengthen:''' When increased shear loading on an existing bent cap is required and a structural analysis shows insufficient bent cap shear resistance, bent cap shear strengthening is an option. An example of when strengthening a bent cap may be required: removing existing girder hinges and making girders continuous will draw significantly more force to the adjacent bent. An example of when strengthening a bent cap is not required: redecking a bridge where analysis shows that the existing bent cap cannot meet capacity for an HS20 truck loading, and the new deck is similar to the old deck and the existing beam is in good shape. | |

| + | '''How to strengthen:''' Using FRP systems for shear strengthening follows from the guidelines set forth in ''NCHRP Report 678, Design of FRP System for Strengthening Concrete Girders in Shear''. The method of strengthening, using either discrete strips or continuous sheets, is made optional for the contractor in accordance with ''NCHRP Report 678''. A Bridge Standard Drawing and Bridge Special Provision have been prepared for including this work on jobs. They can be revised to specify a preferred method of strengthening if desired, strips or continuous sheet. | ||

| − | + | '''What condition of existing bent cap required for strengthening:''' If a cap is in poor shape where replacement should be considered, FRP should not be used. Otherwise, the cap beam can be repaired before applying FRP. Perform a minimum load check using (1.1DL + 0.75(LL+I))'''*''' on the existing cap beam to prevent catastrophic failure of the beam if the FRP fails (''ACI 440.2R, Guide for the Design and Construction of Externally Bonded FRP, Sections 9.2 and 9.3.3''). If the factored shear resistance of the cap beam is insufficient for meeting the factored minimum load check, then FRP strengthening should not be used. | |

| + | |||

| + | :: '''*''' ACI 440.2R: ''Guide for the Design and Construction of Externally Bonded FRP'' | ||

| + | '''Design force (net shear strength loading):''' Strengthening a bent cap requires determining the net factored shear loading that the cap beam must carry in excess of its unstrengthened factored shear capacity, or resistance. The FRP system is then designed by the manufacturer to meet this net factored shear load, or design force. The design force for a bent cap strengthening is calculated considering AASHTO LFD where the factored load is the standard Load Factor Group I load case. To determine design force that the FRP must carry alone, the factored strength of the bent cap, which is 0.85 x nominal strength according to LFD design, is subtracted out to give the net factored shear load that the FRP must resist by itself. ''NCHRP Report 678'' is referenced in the special provisions as guidelines for the contractor and the manufacturer to follow. The report and its examples use AAHTO LRFD. <u>Regardless, the load factor case is given and it is left to the manufacturer to provide for a satisfactory factor of safety based on their FRP system.</u> | ||

| − | + | Other References: | |

| + | :: '''*''' ACI 201.1R: ''Guide for Making a Condition Survey of Concrete in Service'' | ||

| + | :: '''*''' ACI 224.1R: ''Causes, Evaluation, and Repair of Cracks in Concrete'' | ||

| + | :: '''*''' ACI 364.1R-94: ''Guide for Evaluation of Concrete Structures Prior to Rehabilitation'' | ||

| + | :: '''*''' ACI 440.2R-08: ''Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures'' | ||

| + | :: '''*''' ACI 503R: ''Use of Epoxy Compounds with Concrete'' | ||

| + | :: '''*''' ACI 546R: ''Concrete Repair Guide'' | ||

| + | :: '''*''' International Concrete Repair Institute (ICI) ICI 03730: ''Guide for Surface Preparation for the Repair of Deteriorated Concrete Resulting from Reinforcing Steel Corrosion'' | ||

| + | :: '''*''' International Concrete Repair Institute (ICI) ICI 03733: ''Guide for Selecting and Specifying Materials for Repairs of Concrete Surfaces'' | ||

| + | :: '''*''' NCHRP Report 609: ''Recommended Construction Specifications Process Control Manual for Repair and Retrofit of Concrete Structures Using Bonded FRP Composites'' | ||

| − | ===751.40.3. | + | ===751.40.3.3 Steel HP Pile Maintenance and Repair=== |

| + | |||

| + | '''Maintenance/Repair Guidelines''' | ||

| − | + | Piles are primary structural members and are compressively loaded all the time which makes it important to safely inspect, maintain and repair them if necessary. Pile inspection will require an assessment of pile performance by looking for pile deterioration and measuring pile section loss in order to determine the level of pile maintenance/repair required. The following schedule may be used for selecting the level of maintenance/repair required: | |

| − | ''' | + | {| class="wikitable" style="cellpadding="5" align="center" |

| + | |- | ||

| + | ! Pile Percent Section Loss !! Method'''*''' !! Level | ||

| + | |- | ||

| + | | 0% through 25% || Clean and recoat existing piles || Maintenance | ||

| + | |- | ||

| + | | >25% through 40% || Encasement of deteriorated section || Maintenance | ||

| + | |- | ||

| + | | >40% through 75% or holes in any element or local buckling of any element || Plating ** of deteriorated section OR replacement *** of section (splicing), AND encasement of the repaired section || Repair | ||

| + | |- | ||

| + | | >75% || Contact the Bridge Division || Repair | ||

| + | |- | ||

| + | | colspan="3" | '''*''' Method may also include cleaning and recoating all exposed piles, and cleaning and recoating all remaining exposed pile sections after encasement and/or repair. | ||

| + | |- | ||

| + | | colspan="3" | '''**''' Plating can be for both flanges only, web only or both flanges and web. Overall symmetry of the pile cross-section shall be maintained when plating. | ||

| + | |- | ||

| + | | colspan="3" | '''***''' Based on additional factors other than just the percent of pile section loss, a replacement pile section (splicing) may be considered. Minimizing or eliminating traffic loading, adding falsework or just having support conditions such as integral bents (where both the pile cap beam and the superstructure concrete diaphragm are connected by more than just dowel bars – see bridge plans) can help to determine the method of repair. A replacement pile section can be coated or galvanized. See Structural Project Manager. | ||

| + | |} | ||

| + | '''Estimating Pile Percent Section Loss in the Field''' | ||

| + | Quantifying pile section loss can be inexact. To encourage uniform application of the maintenance/repair guidelines, the following procedure is recommended: | ||

| − | + | :1. Pile section loss should be determined using a thickness meter. | |

| + | :2. Remove deteriorated material and clean pile for measurement. | ||

| + | :3. At any point along a pile (cross-section) where there are three elements to be considered independently, e.g. two flanges and a web. | ||

| + | :4. Estimate the actual cross-section area of each element at its most deteriorated point along the length of pile. Using the thickness meter, measure the thickness at several points along a horizontal line across the element. From this data, estimate the actual cross-section area of each element. | ||

| + | :5. The fraction of section remaining (PSR) is the actual cross-section area of each element at its most deteriorated point along the length of pile divided by the original area of same element. | ||

| + | :6. Percent section loss is 100(1 – PSR) for each element. | ||

| + | :7. The greatest PSR dictates the maintenance/repair method. | ||

| + | :8. Examine continuity at flange/web intersections. Section loss along these intersections along the length of pile of more than 6 linear inches should be repaired using encasement as either the only method or part of plating/replacing repair method regardless of a low percent section loss. | ||

| + | :9. Interference from cross bracing at pile sections to be repaired will need special consideration not detailed on the standard drawings. | ||

| + | {| class="wikitable" style="margin: 0 auto; text-align: center" | ||

| + | |+ | ||

| + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | ||

| + | |- | ||

| + | | Rehabilitation, Surfacing & Widening – RHB; Steel HP Pile Maintenance and Repair | ||

| + | |} | ||

| − | + | Additional types of maintenance and repairs may be considered which include but are not limited to: | |

| + | :* Zinc tape coating | ||

| + | :* FRP strengthening | ||

| + | :* Corrosion inhibitor | ||

| + | ==751.40.4 Barriers and Railings== | ||

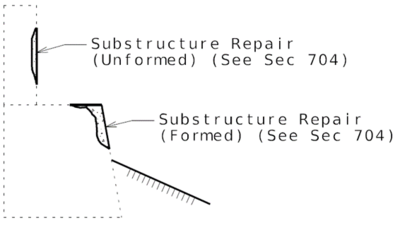

| + | ===751.40.4.1 End Post Modification for 12-inch Vertical Barrier (Safe & Sound Bridges)=== | ||

| + | The 12-inch vertical barrier requires modification to allow attachment of the transition for the Midwest Guardrail System. | ||

| − | + | {| class="wikitable" style="margin: 0 auto; text-align: center" | |

| − | + | |+ | |

| − | + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | |

| − | + | |- | |

| + | | Barrier End Modifications – BEM & CBO/Barrier End Modification – BEM | ||

| + | |} | ||

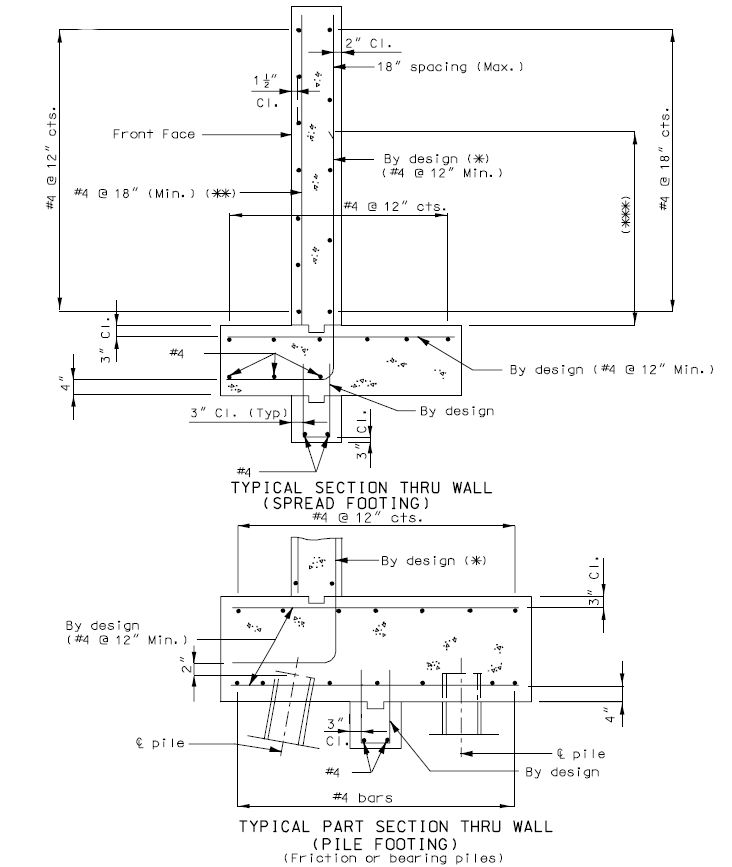

| + | ===751.40.4.2 Replacement of Existing Type B Barrier Using Anchor Systems=== | ||

| − | + | '''NEW BARRIER ON SLAB''' | |

| − | | | + | {| style="text-align: center; margin: 0 auto;" |

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_(Safety_Barrier_Curb_on_Slab)_Section_Thru_Curb.gif]] |

|- | |- | ||

| − | | | + | | '''SECTION THRU BARRIER''' |

|} | |} | ||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | {| | ||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_(Safety_Barrier_Curb_on_Slab)_Section_Thru_Curb_Optional_Anchoring_System.gif]] |

|- | |- | ||

| − | | | + | | '''SECTION THRU BARRIER'''<br/>'''(OPTIONAL ANCHORING SYSTEM)''' |

|- | |- | ||

| − | | | + | | See [[751.50 Standard Detailing Notes#I2. Resin & Cone Anchors|EPG 751.50 I2. Resin & Cone Anchors]] for appropriate notes. |

|} | |} | ||

| − | + | '''NEW BARRIER ON WING''' | |

| − | | | + | {| style="text-align: center; margin: 0 auto;" |

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_(Safety_Barrier_Curb_on_Wing)_Section_Thru_Curb.gif]] |

| + | |- | ||

| + | | '''SECTION THRU BARRIER(*)''' | ||

|} | |} | ||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| − | {| | ||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_(Safety_Barrier_Curb_on_Wing)_Section_Thru_Curb_Optional_Anchoring_System.gif]] |

|- | |- | ||

| − | + | | '''SECTION THRU BARRIER(*)'''<br/>'''(OPTIONAL ANCHORING SYSTEM)''' | |

| − | |||

| − | |||

|} | |} | ||

| + | :Note: See [[751.50 Standard Detailing Notes#I2. Resin & Cone Anchors|EPG 751.50 I2. Resin & Cone Anchors]] for appropriate notes. For details not shown, see [[751.12 Barriers, Railings, Curbs and Fences|EPG 751.12 Barriers, Railings, Curbs and Fences]]. | ||

| + | '''REPLACEMENT OF EXISTING BARRIER AT END OF WING USING ANCHOR SYSTEMS''' | ||

'''INTEGRAL END BENTS''' | '''INTEGRAL END BENTS''' | ||

| + | {| style="text-align: center; margin: 0 auto;" | ||

| + | |- | ||

| + | | style="text-align:left; width: 250px" | (*)Extend existing horizontal bars 2'-3" into new concrete.</br>(**) Fit bar to follow transition face of barrier.</br>Note: For details of guardrail attachment, see barrier standard drawings. || rowspan="2" | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Integral_End_Bents)_Part_Elevation.gif]] | ||

| + | |- | ||

| + | | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Integral_End_Bents)_Anchor_Systems_at_Section_CC.gif]] | ||

| + | |- | ||

| + | | '''ANCHOR SYSTEMS AT SECTION C-C''' || '''PART ELEVATION''' | ||

| + | |- | ||

| + | |} | ||

| − | |||

| − | | | + | {| style="text-align: center; margin: 0 auto;" |

| − | |||

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Integral_End_Bents)_Section_AA.gif]] || [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Integral_End_Bents)_Section_BB.gif]] || [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Integral_End_Bents)_Section_CC.gif]] |

|- | |- | ||

| − | | | + | | '''SECTION A-A''' || '''SECTION B-B''' || '''SECTION C-C''' |

|- | |- | ||

| − | |||

|} | |} | ||

| − | + | '''REPLACEMENT OF EXISTING BARRIER AT END OF WING USING ANCHOR SYSTEMS''' | |

| + | |||

| + | '''NON-INTEGRAL END BENTS''' | ||

| − | |Note:|| | + | {| style="text-align: center; margin: 0 auto;" |

| + | |- | ||

| + | | style="text-align:left; width: 250px" | (*)Extend existing horizontal bars 2'-3" into new concrete.</br>(**) Fit bar to follow transition face of barrier.</br>Note: For details of guardrail attachment, see barrier standard drawings. || rowspan="2" | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Non-Integral_End_Bents)_Part_Elevation.gif]] | ||

| + | |- | ||

| + | | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Non-Integral_End_Bents)_Anchor_Systems_at_Section_CC.gif]] | ||

| + | |- | ||

| + | | '''ANCHOR SYSTEMS AT SECTION C-C''' || '''PART ELEVATION''' | ||

| + | |- | ||

|} | |} | ||

| − | + | {| style="text-align: center; margin: 0 auto;" | |

| − | {| | ||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Non-Integral_End_Bents)_Section_AA.gif]] || [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Non-Integral_End_Bents)_Section_BB.gif]] | [[Image:751.40_Replacement_of_Existing_Curb_at_End_of_Wing_(Non-Integral_End_Bents)_Section_CC.gif]] |

|- | |- | ||

| − | | | + | | '''SECTION A-A''' || '''SECTION B-B''' || '''SECTION C-C''' |

|- | |- | ||

| − | |||

|} | |} | ||

| − | |||

| − | + | ===751.40.4.3 Replacement of Existing Rail with Thrie Beam Rail=== | |

| + | As a matter of policy, blockouts for thrie beam railings are required while FHWA does show similar systems without blockouts as NCHRP 350 approved. See the Structural Project Manager (SPM) or the Structural Liaison Engineer (SLE), if practical, to omit blockout. A design exception shall be required. Blockouts shall always be required on major routes. | ||

| − | + | There are four systems for use on state routes. In these four systems the connection design load used is 1.5 times plastic moment capacity (Mp) of W6 x 20 Post. The vertical clearance of System 3 shall be checked due to the obtruding lower connection. | |

| + | {| class="wikitable" style="margin: 0 auto; text-align: center" | ||

| + | |+ | ||

| + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | ||

| + | |- | ||

| + | | Thrie Beam Rails - THRIE | ||

| + | |} | ||

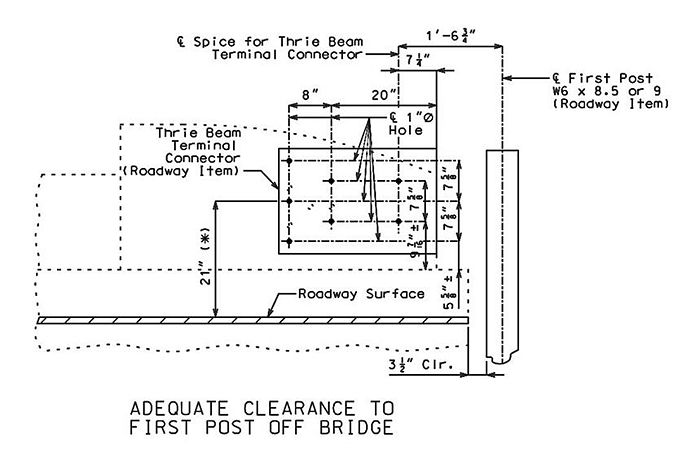

| − | + | ===751.40.4.4 End Treatment Using Thrie Beam Rail=== | |

| + | [[image:751.40.4.4.jpg|center|700px]] | ||

| − | + | [[image:751.40.4.4 clearance.jpg|center|700px]] | |

| − | + | Guidance for Design: | |

| + | :Adequate clearance to first post off bridge shall be required. (See also [https://www.modot.org/media/16893 Standard Plan 617.10] for new bridges.) | ||

| + | ===751.40.4.5 Curb Blockouts=== | ||

| − | + | See [[751.1_Preliminary_Design#751.1.3.4_Barrier_or_Railing_Type.2C_Height_and_Guidelines_for_Curb_Blockouts | EPG 751.1.3.4 Barrier or Railing Type, Height and Guidelines for Curb Blockouts]] for usage guidance. | |

| + | {| class="wikitable" style="margin: 0 auto; text-align: center" | ||

| + | |+ | ||

| + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | ||

| + | |- | ||

| + | | Barrier Modifications – BEM & CBO/Curb Blockouts - CBO | ||

| + | |} | ||

| + | ==751.40.5 Drainage== | ||

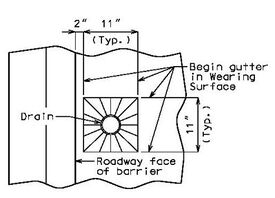

| − | + | ===751.40.5.1 Structure with Wearing Surface Slab Drains - Details=== | |

| + | '''Two material options may be used for slab drains: | ||

| − | + | :'''1. Steel Slab Drains''' and inserts are only shown in the following details. | |

| + | :'''2. Fiberglass Reinforced Polymer (FRP)''' drains may be used with the approval of the Structural Project Manager or Structural Liaison Engineer. See [https://epg.modot.org/index.php?title=751.10_General_Superstructure#751.10.3.2.1_New_Structure_Without_Wearing_Surface_Slab_Drains_-_Details EPG 751.10.3.2.1 New Structure Without Wearing Surface Slab Drains - Details] for guidance and details of FRP drains on new structures as an aid. | ||

| − | + | :A positive mechanical connection must be used for attaching FRP drains to either existing steel drains or to new FRP inserts since welding cannot be used as is shown in the following details for steel drains. For example, using at least four bolt-through connectors (one per side) from new FRP drains into a new wearing surface or an existing steel drain, or using an epoxy adhesive in conjunction with at least two bolt-through connectors is required. It has been shown that using a more viscous epoxy or anchoring gel is beneficial in order to avoid dripping during placement. Using epoxy adhesive or an anchoring gel by itself is not acceptable. | |

| + | :FRP drain may not fit exactly to the inside or to the outside of existing steel drain. The looseness of fit can be addressed by considering a combination of attachment details like mechanical connectors (to existing slab drain) plus either a viscous epoxy adhesive or a positive attachment to an exterior girder depending on the length of the slab drain extension. | ||

| + | '''For new wearing surface over new slab, note on plans:''' | ||

| − | + | :Piece "A" shall be cast in the concrete slab. Prior to placement of wearing surface, piece "B" shall be inserted into piece "A". | |

| − | + | '''FOR STRUCTURE WITH WEARING SURFACE'''<br/>'''(GIRDER DEPTH LESS THAN 48")''' | |

| − | + | <center>[[Image:751.40_Slab_Drain_Details_(Girder_Depth_Less_than_48_in.)_Part_Elev_of_Slab_at_Drain.gif]]</center> | |

| + | <center>'''PART ELEVATION OF SLAB AT DRAIN'''</center> | ||

| − | |||

| − | |||

| + | <center>[[Image:751.40_Slab_Drain_Details_(Girder_Depth_Less_than_48_in.)_Elev_of_Drain.gif]]</center> | ||

| − | |||

| − | + | <center>'''ELEVATION OF DRAIN'''</center> | |

| − | {|border="0" | + | |

| + | {|border="0" align="center" | ||

| − | | | + | |*||Deck thickness minus 1/8" minus the depth of the scarification. |

|- | |- | ||

| − | | | + | |**||Do not include the depth of the scarification. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| + | | ||

| + | | ||

| + | | ||

| − | |||

| − | + | <center>[[Image:751.40_Slab_Drain_Details_(Girder_Depth_Less_than_48_in.)_Plan_of_Drain.gif]]</center> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <center>'''PLAN OF DRAIN'''</center> | ||

| − | |||

| − | |||

| + | '''FOR STRUCTURE WITH WEARING SURFACE'''<br/>'''(GIRDER DEPTH 48" AND OVER)''' | ||

| − | |||

| − | + | {|border="0" cellpadding="5" align="center" style="text-align:center" | |

| − | {|border="0" | ||

| − | | | + | |rowspan="3"|[[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Part_Elevation_of_Slab_at_Drain.gif]] |

| + | |[[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Elev_of_Drain.gif]] | ||

|- | |- | ||

| − | | | + | |'''ELEVATION OF DRAIN'''<!--cell a occupied by [[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Part_Elevation_of_Slab_at_Drain.gif]]--> |

| + | |- | ||

| + | |[[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Plan_of_Drain.gif]]<!--cell a occupied by [[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Part_Elevation_of_Slab_at_Drain.gif]]--> | ||

|- | |- | ||

| − | | | + | |'''PART ELEVATION OF SLAB AT DRAIN'''||'''PLAN OF DRAIN''' |

|} | |} | ||

| − | | | + | |

| + | ::{|border="0" | ||

| + | |||

| + | |valign="top"|*||If dimension is less than 1", drains shall be placed parallel to roadway. Otherwise, place drains transverse to roadway. | ||

|- | |- | ||

| − | | | + | |valign="top"|**||Do not include the depth of the scarification. |

|- | |- | ||

| − | | | + | |valign="top"|***||Deck thickness minus 1/8" minus the depth of the scarification. |

|} | |} | ||

| − | |||

{|border="0" align="center" style="text-align:center" | {|border="0" align="center" style="text-align:center" | ||

| − | + | |colspan="2"|[[Image:751.40_Slab_Drain_Details_(Girder_Depth_48_in._and_over)_Part_Plans_Showing_Bracket_Assembly.gif]] | |

| − | | | ||

| − | |[[Image:751. | ||

| − | |||

|- | |- | ||

| − | |''' | + | |'''DRAIN TRANSVERSE TO ROADWAY'''||'''DRAIN PARALLEL TO ROADWAY''' |

|- | |- | ||

| − | | || | + | | |

| + | |- | ||

| + | |colspan="2"|'''PART PLANS SHOWING BRACKET ASSEMBLY''' | ||

|} | |} | ||

| − | |||

| − | + | '''FOR STRUCTURE WITH WEARING SURFACE'''<BR/>'''(CONTINUOUS CONCRETE STRUCTURES)''' | |

| − | |||

| + | <center>[[Image:751.40_Slab_Drain_Details_(Continuous_Concrete_Structures)_Part_Section_Near_Drain.gif]]</center> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <center>'''PART SECTION NEAR DRAIN'''</center> | ||

| − | |||

| − | |||

| − | [[ | + | <center>[[Image:751.40 Slab Drain Details (Continuous Concrete Structures) Elevation of Drain.gif]]</center> |

| − | [[ | + | <center>'''ELEVATION OF DRAIN'''</center> |

| + | |||

| + | |||

| + | |||

| + | <center>[[Image:751.40_Slab_Drain_Details_(Continuous_Concrete_Structures)_Plan_of_Drain.gif]]</center> | ||

| + | |||

| + | <center>'''PLAN OF DRAIN'''</center> | ||

| − | |||

| − | + | {|border="0" align="center" | |

| − | + | |*||Deck thickness minus 1/8" minus the depth of the scarification. | |

| + | |- | ||

| + | |**||Do not include the depth of scarification. | ||

| + | |} | ||

| − | |||

| − | |||

| − | + | '''FOR STRUCTURE WITH WEARING SURFACE'''<BR/>'''(VARIABLE DEPTH GIRDERS)''' | |

| − | |||

| − | : | + | <center>[[Image:751.40_Slab_Drain_Details_(Variable_Depth_Girders)_Part_Elevation_of_Slab_at_Drain.gif]]</center> |

| − | |||

| − | ''' | + | <center>'''PART ELEVATION OF SLAB AT DRAIN'''</center> |

| − | |||

| + | Note: For variable depth girders with drains in deeper section, let the deeper section control and use throughout the structure. | ||

| − | |||

| − | <center>[[Image:751.40_Slab_Drain_Details_( | + | <center>[[Image:751.40_Slab_Drain_Details_(Variable_Depth_Girders)_Typ_Section_Straight_Drain.gif]]</center> |

| − | <center>''' | + | <center>'''TYPICAL SECTION STRAIGHT DRAIN'''</center> |

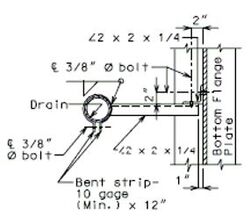

| + | ===751.40.5.2 Structure with Wearing Surface Round Slab Drains - Details=== | ||

| + | '''FOR STRUCTURE WITH WEARING SURFACE'''<BR/>'''MISCELLANEOUS DETAILS - ROUND DRAINS''' | ||

| − | + | FRP round drains may be used optionally unless otherwise specified. See [https://epg.modot.org/index.php?title=751.10_General_Superstructure#751.10.3_Bridge_Deck_Drainage_-_Slab_Drains EPG 751.10.3 Bridge Deck Drainage – Slab Drains] for guidance and details as an aid. Specify nominal pipe size as needed referencing ASTM D2996. Specify outer diameter based on nominal pipe size necessary for drainage for coring the correct size hole in deck. | |

| + | Note: See EPG 751.10.3 Bridge Deck Drainage – Slab Drain for slab drain spacing. | ||

| − | |||

| − | {|border="0" align="center" | + | {|border="0" align="center" style="text-align:center" |

| − | | | + | |[[image:751.40.5.2 typical.jpg|center|275px]] |

| + | |[[image:751.40.5.2 section.jpg|center|250px]] | ||

|- | |- | ||

| − | | | + | |'''TYPICAL PART PLAN'''||'''SECTION SHOWING BRACKET ASSEMBLY''' |

|} | |} | ||

| − | |||

| − | |||

| − | |||

| + | <center>[[Image:751.40_Slab_Drain_Details_(Misc._Details_-_Round_Drains)_Typical_Part_Plan_of_Drain.gif]]</center> | ||

| + | |||

| + | |||

| + | <center>'''TYPICAL PART PLAN OF DRAIN'''</center> | ||

| − | <center>[[ | + | <center>Note: See [[751.50 Standard Detailing Notes|EPG 751.50 Standard Detailing Notes]] for appropriate notes.</center> |

| − | + | ===751.40.5.3 Structure with Wearing Surface Raising Slab Drains or Scuppers - Details=== | |

| + | '''FOR STRUCTURE WITH WEARING SURFACE'''<br/>'''RAISING SLAB DRAINS''' | ||

| − | + | <center>[[Image:751.40_Slab_Drain_Details_(Raising_Standard_Slab_Drains)_Part_Section_of_Drain.gif]]</center> | |

| − | + | <center>'''PART SECTION OF DRAIN'''</center> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <center>[[Image:751.40_Slab_Drain_Details_(Raising_Standard_Slab_Drains)_Part_Plan_of_Existing_Drain.gif]]</center> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <center>'''PART PLAN OF EXISTING DRAIN'''</center> | |

| − | + | <center>Note:<br/>Outside dimensions of drain extension are 7-1/4" x 3-1/4", and drain extension shall be galvanized in accordance with ASTM A123.</center> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | '''FOR STRUCTURE WITH WEARING SURFACE'''< | + | '''FOR STRUCTURE WITH WEARING SURFACE'''<br/>'''RAISING SCUPPERS''' |

| − | <center>[[Image:751.40_Slab_Drain_Details_( | + | <center>[[Image:751.40_Slab_Drain_Details_(Details_for_Raising_Scuppers)_Typ_Section_thru_Scupper.gif]]</center> |

| − | |||

| + | <center>'''TYPICAL SECTION THRU SCUPPER'''</center> | ||

| − | |||

| + | <center>[[Image:751.40_Slab_Drain_Details_(Details_for_Raising_Scuppers)_Plan_of_Grate_Support_and_Scupper_Extension.gif]]</center> | ||

| − | |||

| + | <center>'''PLAN OF GRATE SUPPORT'''<BR/>'''AND'''<BR/>'''PLAN OF SCUPPER EXTENSION''' | ||

| − | + | '''*''' Plate thicknesses should match those of existing scupper and existing grate.</center> | |

| + | ===751.40.5.4 Cored Slab Drains=== | ||

| + | Cored slab drains may be installed in areas where the existing drainage is a concern, but the deck is not in need of replacement. Typically, 4-inch diameter drains are installed vertically to avoid the deck reinforcing steel which is typically spaced at 5-inch centers. If necessary, larger diameter drains or angled drains may be used with approval of the SPM or SLE. | ||

| − | + | {| border="1" class="wikitable" style="margin: 0 auto; text-align: center" | |

| − | + | |+ | |

| − | + | | style="background:#BEBEBE" | '''[https://www.modot.org/bridge-standard-drawings Bridge Standard Drawings]''' | |

| − | {|border=" | ||

| − | |||

| − | | | ||

|- | |- | ||

| − | | | + | | Rehabilitation, Surfacing & Widening - RHB/Cored Slab Drain for Existing Bridge Deck [RHB18] |

|} | |} | ||

| + | ==751.40.6 Closure Pour== | ||

| − | + | Note: | |

| + | For closure pour on solid slab or voided slab bridges, use expansive concrete. | ||

| − | + | Release the forms before the closure pour is placed. | |

| − | |||

| + | <center>[[Image:751.40_Closure_Pour_-_Part_Section_Thru_Roadway.gif]]</center> | ||

| − | |||

| + | <center>'''PART SECTION THRU ROADWAY'''</center> | ||

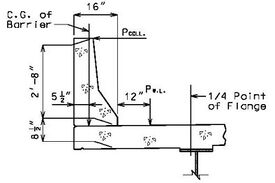

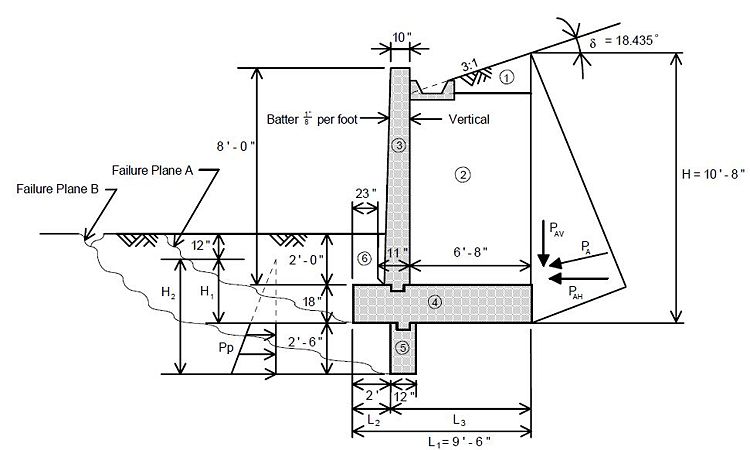

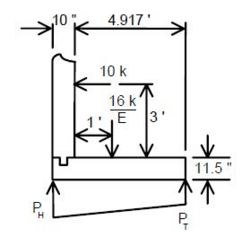

| − | + | ==751.40.7 Design and Posting Considerations== | |

| − | + | Existing structures to redecked and/or widened should be evaluated to determine if the superstructure is considered to be structurally adequate. The structural adequacy check should be determined based on load ratings using the Load Factor Method. Strengthening of the superstructure will not be required if the minimum posting values shown below meet or exceed legal load requirements. In addition, there may be cases where the existing bridge posting is acceptable based on the bridge specific site conditions such as AADT, amount of truck traffic, overweight permit route, etc. | |

| − | = | + | |

| + | {|border="0" | ||

| − | + | |1)||H20 (one lane with Impact) [Posting Rating] ≥ 23 tons | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | |||

|- | |- | ||

| − | | | + | |2)||3S2 (one lane with impact) [Posting Rating] ≥ 40 tons |

|} | |} | ||

| + | Posting Rating = 86% of Load Factor Operating Rating (Refer to figures below for H20, 3S2 and MO5 criteria). | ||

| − | + | If a structure is located within a commercial zone, then the following additional posting condition must be investigated: | |

| + | {|border="0" | ||

| − | + | |3)||M05 (two lane with impact) [Operating Rating] ≥ 70 Tons (posting limit) | |

| + | |} | ||

| + | Any other overstresses or inadequacies (slab, substructure, etc.) shall be reported to the Structural Project Manager. | ||

| − | + | Deck thickness for redecks shall be determined such that Posting will not be required or the existing posting is not lowered, and it is generally not less than original deck thickness. | |

| + | Deck thickness for widenings shall be existing thickness unless thicker slab does not create overall deck stiffening irregularities. | ||

| − | + | See Structural Project Manager if AASHTO minimum deck thickness can not be used on redecks and widenings. | |

| − | |||

| + | Future Wearing Surface (FWS) Loadings for widenings with concrete wearing surfaces - In addition to weight of wearing surface: | ||

| − | + | :Add FWS of 35 psf to the design of new girders if existing girders are sufficient for the 35 psf FWS | |

| + | |||

| + | :Lower FWS loading to 15 psf if existing girders are not sufficient for FWS loading of 35 psf | ||

| + | |||

| + | :If existing girders are not sufficient for any FWS then lower FWS to FWS = 0. | ||

| + | |||

| + | :The existing ratings should be reviewed to determine what wearing surface loads were used. When necessary, the rating should be evaluated for acceptability of the proposed changes in the wearing surface loads and geometry. Preliminary ratings that are based on estimated geometry shall be revised when the updated, final geometry is known. | ||

| − | |||

| + | <center>[[Image:751.40_Posting_Rating_(H20_Legal_Truck).gif]]</center> | ||

| − | <center>[[Image:751. | + | <center>[[Image:751.40_Posting_Rating_(3S2_Truck).gif]]</center> |

| − | <center> | + | <center>[[Image:751.40_Posting_Rating_(MO5_Truck).gif]]</center> |

| − | + | == 751.40.8 Design Information when using AASHTO Standard Specifications for Highway Bridges 17th Edition == | |

| − | + | === 751.40.8.1 Loadings === | |

| − | |||

| + | ==== 751.40.8.1.1 Live Load ==== | ||

| − | + | Structures shall be designed to carry the dead load, live load, impact (or dynamic effect of the live load), wind load and other forces, when they are applicable. | |

| + | Members shall be designed with reference to service loads and allowable stresses as provided in AASHTO (17th edition) Service Load Design Method (Allowable Stress Design) or with reference to factored load and factored strength as provided in AASHTO Strength Design Method (Load Factor Design). Load groups represent various combination of loads and forces to which a structure may be subjected. Group loading combinations for Service Load Design and Load Factor Design are given by AASHTO (17th edition) 3.22.1 and AASHTO (17th edition) Table 3.22.1A. | ||

| + | The live load shall consist of the applied moving load of vehicles and pedestrians. The design live load to be used in the design of bridges for the state system will be as stated on the Bridge Memorandum. | ||

| + | *The design truck: HS20-44 or HS20-44 Modified | ||

| + | *The design tandem (Military) | ||

| + | *The design lane loading | ||

| − | |||

| + | '''Criteria''' | ||

| + | #All widened or retrofitted bridges on the National Highway System and in commercial zones may be designed for HS20-44 Modified loading. All remaining bridges will be designed for HS20-44 loading. | ||

| + | #The Design Tandem loading is to be checked on national highway system or when Alternate Military loading appears on the Bridge Memorandum. | ||

| + | #Carrying members of each structure shall be investigated for the appropriate loading. | ||

| + | #*Main carrying members include: | ||

| + | #**Steel or Concrete stringers or girders. | ||

| + | #**Longitudinally reinforced concrete slabs supported on transverse floor beams or substructure units (includes hollow slabs). | ||

| + | #**Transversely reinforced concrete slabs supported by main carrying members parallel to traffic and over 8'-0" center to center. Use the formulas for moment in AASHTO Article 3.24.3.1 Case A. | ||

| + | #**Steel grid floors when the main elements of the grid extend in a direction parallel to traffic, or with main elements transverse to traffic on supports more than 8'-0" apart. | ||

| + | #**Timber floors and orthotropic steel decks. | ||

| + | #The reduction in live load for calculating substructure members is based on AASHTO 3.12.1. See Live Load Distribution in the Load Distribution Section. | ||

| − | |||

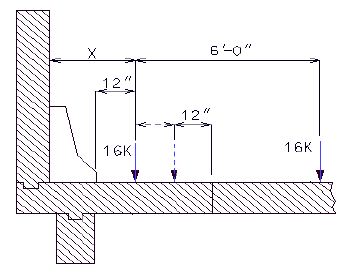

| + | '''HS20-44 Truck Loading''' | ||

| − | + | The HS20-44 truck is defined below as one 8 kip axle load and two 32 kip axle loads spaced as shown. | |

| − | + | <center>[[Image:751.40 loadings-hs20-44 truck loading(side).gif]]</center> | |

| − | + | Varies = Variable spacing 14’ to 30’ inclusive. Spacing to be used is that which produces the maximum stresses. | |

| − | |||

| − | + | <center>[[Image:751.40 loadings-hs20-44 truck loading(back).gif]]</center> | |

| + | <center>'''HS20-44 Design Truck'''</center> | ||

| − | + | (*) In the design of timber floors and orthotropic steel decks (excluding transverse beams) for H-20 Loading, one axle load of 24 kips or two axle loads of 16 kip each, spaced 4 feet apart may be used, whichever produces the greater stress, instead of the 32 kip axle load shown. | |

| + | (**) For slab design, the center line of wheels shall be assumed to be one foot from face of cur | ||

| − | |||

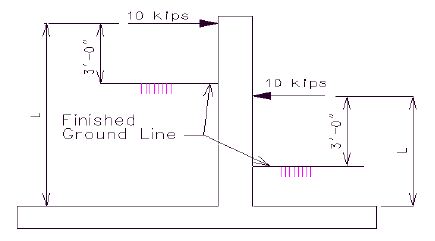

| + | '''HS20-44 Modified Truck Loading''' | ||

| − | + | The HS20-44 Modified truck is defined below as one 10 kip axle load and | |

| + | two 40 kip axle loads spaced as shown. This is the same as HS20-44 truck modified by a factor of 1.25. | ||

| + | <center>[[Image:751.40 loadings-hs20-44 modified truck loading(side).gif]]</center> | ||

| − | |||

| − | + | Varies = Variable spacing 14’ to 30’ inclusive. Spacing to be used is that which produces the maximum stresses. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <center>[[Image:751.40 loadings-hs20-44 modified truck loading(back).gif]]</center> | ||

| − | + | <center>'''HS20-44 Modified Design Truck'''</center> | |

| − | |||

| − | + | (*) For slab design, the center line of wheels shall be assumed to be one foot from face of curb. | |

| − | |||

| − | |||

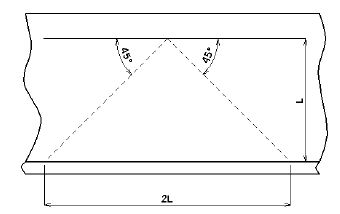

| − | + | '''Design Tandem Loading''' | |

| − | + | The Design Tandem Loading is a two axle load each of 24 kips. These axles are spaced at 4'-0" centers. The transverse spacing of wheels shall be taken as 6'-0". | |

| − | + | <center>[[Image:751.40 loadings-design tandem loading(plan view).gif]]</center> | |

| − | + | <center>'''Design Tandem Loading - Plan View'''</center> | |

| − | |||

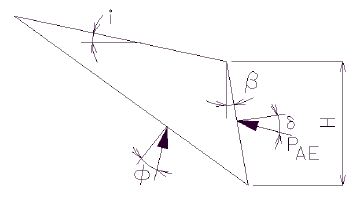

| − | + | '''Design Lane Loading''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | *For HS20-44 Truck, the design lane load shall consist of a load 640 lbs per linear foot, uniformly distributed in the longitudinal direction with a single concentrated load (or two concentrated loads in case of continuous spans for determination of maximum negative moment), so placed on the span as to produce maximum stress. The concentrated load and uniform load shall be considered as uniformly distributed over a 10'-0" width on a line normal to the center line of the lane. | ||

| + | *For HS20-44 Modified Truck, use the HS20-44 truck modified by a factor of 1.25. | ||

| − | <center>[[Image:751. | + | <center>[[Image:751.40 loadings-design lane loading.gif]]</center> |

| + | <center>'''Design Lane Loading'''</center> | ||

| − | + | *For the design of continuous structures, an additional concentrated load is placed in another span to create the maximum effect. For positive moments, only one concentrated load is used, combined with as many spans loaded uniformly as are required to produce the maximum moment. | |

| − | + | '''Standard Roadway Width''' | |

| − | + | :26'-0" (up to 2 traffic lanes) | |

| + | :28'-0" (up to 2 traffic lanes) | ||

| + | :30'-0" (up to 3 traffic lanes) | ||

| + | :32'-0" (up to 3 traffic lanes) | ||

| + | :36'-0" (up to 3 traffic lanes) | ||

| + | :38'-0" (up to 3 traffic lanes) | ||

| + | :40'-0" (up to 4 traffic lanes) | ||

| + | :44'-0" (up to 4 traffic lanes) | ||

| + | ==== 751.40.8.1.2 Impact ==== | ||

| − | + | Highway live loads shall be increased by a factor given by the following formula: | |

| + | <math>\, I = \frac {50}{L + 125}</math> <math>\,L </math> in feet | ||

| + | For continuous spans, <math>\, L</math> to be used in this equation for negative moments is the average of two adjacent spans at an intermediate bent or the length of the end span at an end bent. For positive moments, <math>\, L</math> is the span length from center to center of support for the span under consideration. | ||

| − | + | Impact is never to be more than 30 percent. It is intended that impact be included as part of the loads transferred from superstructure to substructure but not in loads transferred to footings or parts of substructure that are below the ground line. The design of neoprene bearing pads also does not include impact in the design loads. | |

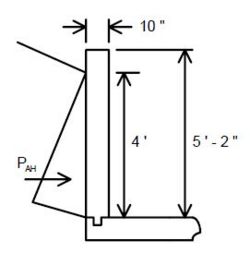

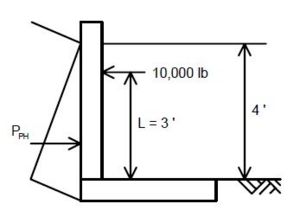

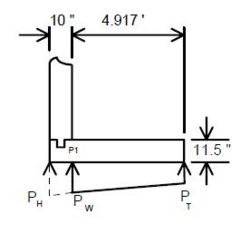

| − | + | ==== 751.40.8.1.3 Collision Force ==== | |

| − | + | Collision forces shall be applied to the barrier or railing in the design of the cantilever slab. A force of 10 kips is to be applied at the top of the standard barrier or railing. This force is distributed through the barrier or railing to the slab. | |

| − | + | ==== 751.40.8.1.4 Centrifugal Force ==== | |

| − | |||

| − | |||

| − | |||

| + | Structures on curves shall be designed for a horizontal radial force equal to the following percentage of the live load in all the lanes, without impact. | ||

| − | + | <math>\, C = \frac {6.68 S^2}{R}</math> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | Where: | ||

| + | {| | ||

| + | |<math>\, C</math>||= the centrifugal force in percent of the live load | ||

| + | |- | ||

| + | |<math>\, S</math>||= the design speed in miles per hour | ||

| + | |- | ||

| + | |<math>\, R</math>||= the radius of the curve in feet | ||

| + | |} | ||

| − | + | This force shall be applied at 6 feet above the centerline of the roadway with one design truck being placed in each lane in a position to create the maximum effect. Lane loads shall not be used in calculating centrifugal forces. | |

| − | |||

| − | |||

| − | + | The effects of superelevation shall be taken into account. | |

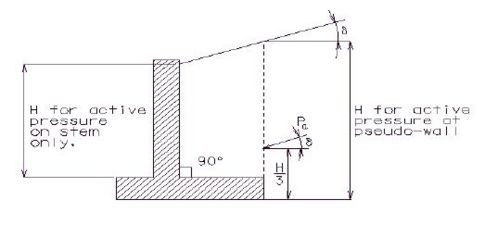

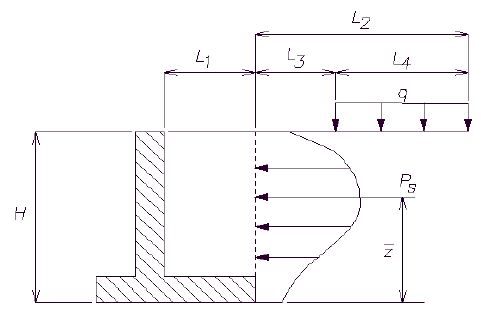

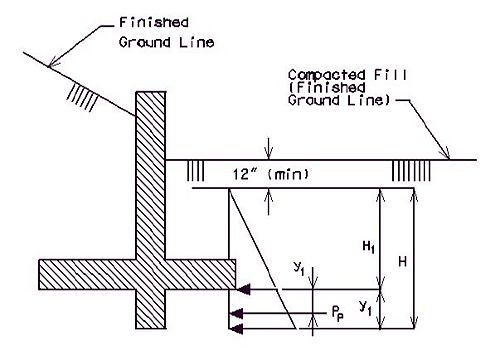

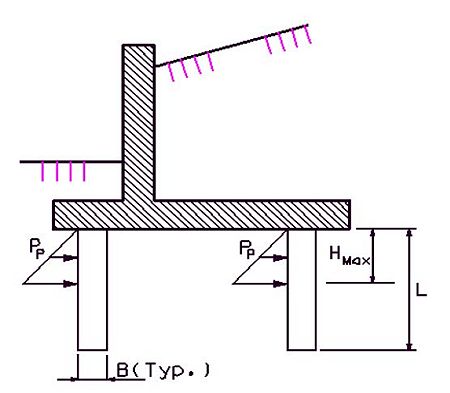

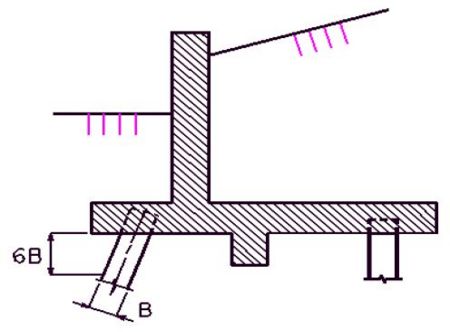

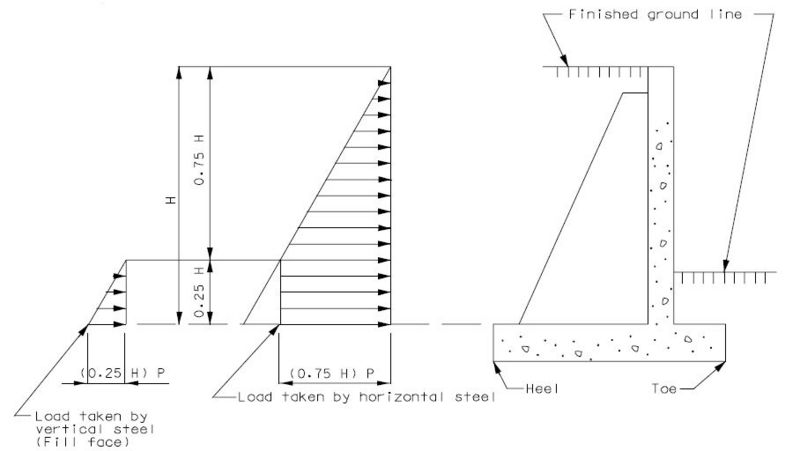

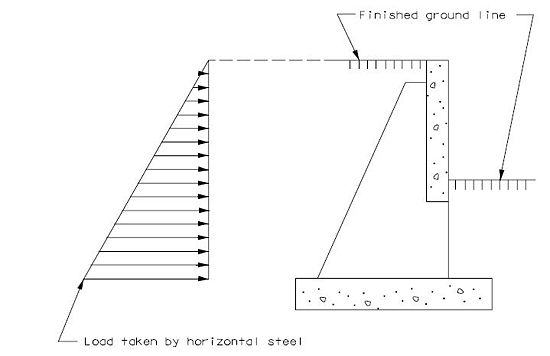

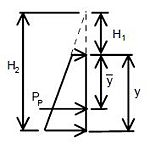

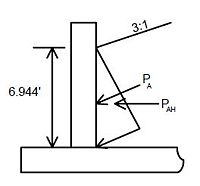

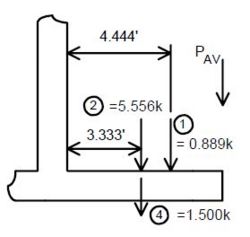

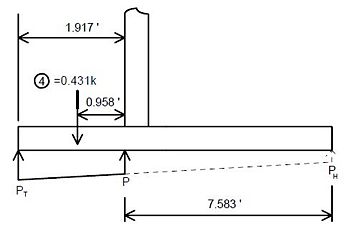

| + | ==== 751.40.8.1.5 Lateral Earth Pressure ==== | ||

| − | + | Structures which retain fills shall be designed for active earth pressures as | |

| + | <math>\, P_a = 0.5 (\gamma K_a) H^2</math> | ||

| − | < | + | Where: |

| + | {| | ||

| + | |<math>\, P_a</math>||colspan="2"|= active earth pressure per length (lb/ft) | ||

| + | |- | ||

| + | |<math>\, \gamma</math>||colspan="2"|= unit weight of the back fill soil = 120 lb/ft³ | ||

| + | |- | ||

| + | |<math>\, K_a</math>||colspan="2"|= coefficient of active earth pressure as given by Rankine’s formula | ||

| + | |- | ||

| + | |<math>\, \gamma K_a</math>||= <math>\, p_a</math>||= equivalent fluid pressure (lb/ft³)(*) | ||

| + | |- | ||

| + | |<math>\, H</math>||colspan="2"|= height of the back fill soil (ft) | ||

| + | |} | ||

| − | |||

| + | '''Rankine's Formula''' | ||

| − | + | The coefficient of active earth pressure <math>\, K_a</math> is: | |

| − | ( | + | <math>\, K_a = (cos \alpha) \Bigg( \frac {cos \alpha - \sqrt{cos^2 \alpha - cos^2 \phi}}{cos \alpha + \sqrt{cos^2 \alpha - cos^2 \phi}} \Bigg)</math> |

| + | Where: | ||

| + | {| | ||

| + | |<math>\, \phi</math>||= angle of internal friction of the backfill soil (*) | ||

| + | |- | ||

| + | |<math>\, \alpha</math>|| = the angle of incline of the backfill | ||

| + | |} | ||

| − | + | If the backfill surface is level, angle a is zero and <math>\, K_a</math> is: | |

| − | + | <math>\, K_a = \frac {1 - sin \phi}{1 + sin \phi}</math> | |

| − | |||

| − | + | (*) Use the internal friction angle indicated on the Bridge Memorandum. However, if the friction angle is not determined, use the minimum equivalent fluid pressure value, <math>\, p_a</math> , of 45 lb/ft³ for bridges and retaining walls. For box culverts use a maximum of 60 lb/ft³ and a minimum of 30 lb/ft³ for fluid pressure. | |

| − | + | '''Live Load Surcharge''' | |

| + | An additional earth pressure shall be applied to all structures which have live loads within a distance of half the structure height. This additional force shall be equal to adding 2'-0" of fill to that presently being retained by the structure. | ||

| − | + | ==== 751.40.8.1.6 Longitudinal Forces (Braking Forces) ==== | |

| − | + | A longitudinal force of 5% of the live load shall be applied to the structure. This load shall be 5% of the lane load plus the concentrated load for moment applied to all lanes and adjusted by the lane reduction factor. Apply this force at 6 feet above the top of slab and to be transmitted to the substructure through the superstructure. | |

| + | ==== 751.40.8.1.7 Wind Load ==== | ||

| − | + | Wind loads shall be applied to the structure regardless of length. | |

| + | The pressure generated by wind load is: | ||

| − | + | <math>\, P = K V^2</math> | |

| − | + | Where: | |

| + | {| | ||

| + | |<math>\, P</math>||= wind pressure in pounds per square foot | ||

| + | |- | ||

| + | |<math>\, V</math>||= design wind velocity = 100 miles per hour | ||

| + | |- | ||

| + | |<math>\, K</math>||= 0.004 for wind load | ||

| + | |} | ||

| − | + | Basic wind load (pressure) = 0.004 x (100)² = 40 lb/ft² | |

| − | |||

| + | '''Wind Load for Superstructure Design''' | ||

| + | '''Transverse''' | ||

| − | + | A wind load of the following intensity shall be applied horizontally at right angles to the longitudinal axis of the structure. | |

| + | *Trusses and Arches = 75 pounds per square foot = <math>\, W_t</math> | ||

| + | *Girders and Beams = 50 pounds per square foot (*) = <math>\, W_t</math> (for plate girder lateral bracing check only) | ||

| + | *The total force shall not be less than 300 pounds per linear foot in the plane of windward chord and 150 pounds per linear foot in the plane of the leeward chord on truss spans, and not less than 300 pounds per linear foot on girder spans. | ||

| − | |||

| − | |||

| + | '''Wind Load for Substructure Design''' | ||

| − | + | Forces transmitted to the substructure by the superstructure and forces applied directly to the substructure by wind load shall be as follows: | |

| − | |||

| − | + | '''Forces from Superstructure: Wind on Superstructure''' | |

| + | '''Transverse''' | ||

| − | + | A wind load of the following intensity shall be applied horizontally at right angles to the longitudinal axis of the structure. | |

| + | *Trusses and Arches = 75 pounds per square foot = <math>\, W_t</math> | ||

| + | *Girders and Beams = 50 pounds per square foot (*) = <math>\, W_t</math> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

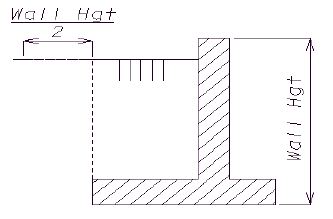

| − | = | + | ''(*) Use Wt = 60 lbs/ft² for design wind force on girders and beams If the column height on a structure is greater than 50 feet, where the height is the average column length from ground line to bottom of beam.'' |

| − | + | The transverse wind force for a bent will be: | |

| − | <math>\, | + | <math>\, P = L \times H \times W_t</math> |

| − | + | Where: | |

| + | {| | ||

| + | |valign="top"|<math>\, L</math>||= length in feet = the average of two adjacent spans for intermediate bents and half of the length of the end span for end bents. | ||

| + | |- | ||

| + | |valign="top"|<math>\, H</math>||= the total height of the girders, slab, barrier or raling and any superelevation of the roadway, in feet | ||

| + | |- | ||

| + | |valign="top"|<math>\, W_t</math>|| = wind force per unit area in pounds per square foot | ||

| + | |} | ||

| − | + | This transverse wind force will be applied at the top of the beam cap for the design of the substructure. | |

| − | |||

| − | + | '''Longitudinal (**)''' | |

| − | + | The standard wind force in the longitudinal direction shall be applied as a percentage of the transverse loading. Use approximately 25%. | |

| − | + | :{| | |

| − | + | |Truss and Arch Structures||<math>\, W_I</math>||= 75 x 0.25 = approximately 20 lbs/ft² | |

| − | |||

| − | |||

| − | |||

| − | {| | ||

| − | |<math>\, | ||

|- | |- | ||

| − | | | + | |Girder Structures||<math>\, W_I</math>||= 50 x 0.25 = approximately 12 lbs/ft² |

| − | |||

| − | |<math>\, | ||

|} | |} | ||

| − | + | The total longitudinal wind force <math>\, P</math> will be: | |

| − | + | <math>\, P = L \times H \times W_I</math> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | <math>\, | ||

Where: | Where: | ||

{| | {| | ||

| − | |<math>\, | + | |<math>\, L</math>||= the overall bridge length in feet |

|- | |- | ||

| − | |<math>\, | + | |valign="top"|<math>\, H</math>||= the total height of the girders, slab, barrier or railing and anysuperelevation of the roadway, in feet |

|- | |- | ||

| − | |<math>\, | + | |<math>\, W_I</math>||= wind force per unit area in pounds per square foot |

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| + | This longitudinal force is distributed to the bents based on their stiffness. (**) | ||

| − | + | The longitudinal wind force for the bent will be applied at the top of the beam cap for the design of the substructure. | |

| − | |||

| − | + | '''Forces from Superstructure: Wind on Live Load''' | |

| − | + | A force of 100 pounds per linear foot of the structure shall be applied transversely to the structure along with a force of 40 pounds per linear foot longitudinally. These forces are assumed to act 6 feet above the top of slab. | |

| − | + | The transverse force is applied at the bents based on the length of the adjacent spans affecting them. The longitudinal force is distributed to the bents based on their stiffness. (**) | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | (**) See [[751.2 Loads#751.2.4.6 Longitudinal Wind Force Distribution|EPG 751.2.4.6 Longitudinal Wind Force Distribution]]. | |

| − | |||

| − | + | '''Forces Applied Directly to the Substructure''' | |

| + | The transverse and longitudinal forces to be applied directly to the substructure elements shall be calculated from an assumed basic wind force of 40 lbs/ft². This wind force per unit area shall be multiplied by the exposed area of each substructure member in elevation (use front view for longitudinal force and side view for transversely force, respectively). These forces are acting at the center of gravity of the exposed portion of the member. | ||

| − | + | A shape factor of 0.7 shall be used in applying wind forces to round substructure members. | |

| − | + | When unusual conditions of terrain or the special nature of a structure indicates, a procedure other than the Standard Specification may be used subject to approval of the Structural Project Manager. | |

| − | ==== 751.40.8.1. | + | ==== 751.40.8.1.8 Temperature Forces ==== |

| − | + | Temperature stresses or movement need to be checked on all structures regardless of length. Generation of longitudinal temperature forces is based on stiffness of the substructure. (*) | |

| − | + | '''Coefficients''' | |

| − | + | :{| | |

| + | |Steel:||Thermal - 0.0000065 ft/ft/°F | ||

| + | |- | ||

| + | |Concrete:||Thermal - 0.0000060 ft/ft/°F | ||

| + | |- | ||

| + | | ||Shrinkage - 0.0002 ft/ft (***) | ||

| + | |- | ||

| + | | ||Friction - 0.65 for concrete on concrete | ||

| + | |} | ||

| − | |||

| − | + | {|border="1" style="text-align:center;" cellpadding="5" align="center" | |

| − | + | |+'''Temperature Range From 60° F (**)''' | |

| − | + | |width="100pt"| ||width="50pt"|Rise||width="50pt"|Fall||width="50pt"|Range | |

| − | |||

| − | | | ||

|- | |- | ||

| − | | | + | |Steel Structures||60°F||80°F||140°F |

|- | |- | ||

| − | | | + | |Concrete Structures||30°F||40°F||70°F |

|} | |} | ||

| − | |||

| + | (*) See [[751.2 Loads#751.2.4.7 Longitudinal Temperature Force Distribution|EPG 751.2.4.7 Longitudinal Temperature Force Distribution]]. | ||

| − | + | (**) Temperature Range for expansion bearing design and expansion devices design see [[751.11 Bearings|EPG 751.11 Bearings]] and [[751.13 Expansion Devices|EPG 751.13 Expansion Devices]], respectively. | |

| − | + | (***) When calculating substructure forces of concrete slab bridges, the forces caused by the shrinkage of the superstructure should be included with forces due to temperature drop. This force can be ignored for most other types of bridges. | |

| − | + | ==== 751.40.8.1.9 Sidewalk Loading ==== | |

| − | |||

| − | |||

| − | |||

| + | Sidewalk floors and their immediate support members shall be designed for a '''live load''' of 85 pounds per square foot of sidewalk area. Girders, trusses, and other members shall be design for the following sidewalk live load: | ||

| − | + | :{| | |

| + | |width="150pt"|Spans 0 to 25 feet||width="100pt"|85 lbs/ft² | ||

| + | |- | ||

| + | |Spans 26 to 100 feet||60 lbs/ft² | ||

| + | |- | ||

| + | |Spans over 100 feet||use the following formula | ||

| + | |} | ||

| − | + | <math>\, P = \Bigg( 30 + \frac {3000}{L} \Bigg) \Bigg( \frac {55-W}{50} \Bigg)</math> | |

| + | Where: | ||

| + | {| | ||

| + | |<math>\, P</math>||= live load per square foot, max. 60 lbs/ft² | ||

| + | |- | ||

| + | |<math>\, L</math>||= loaded length of sidewalk in feet | ||

| + | |- | ||

| + | |<math>\, W</math>||= width of sidewalk in feet | ||

| + | |} | ||

| + | |||

| + | When sidewalk live loads are applied along with live load and impact, if the structure is to be designed by service loads, the allowable stress in the outside beam or stringer may be increased by 25 percent as long as the member is at least as strong as if it were not designed for the additional sidewalk load using the initial allowable stress. When the combination of sidewalk live load and traffic live load plus impact governs the design under the load factor method, use a b factor of 1.25 instead of 1.67. | ||

| + | |||

| + | Unless a more exact analysis can be performed, distribution of sidewalk live loads to the supporting stringers shall be considered as applied 75 percent to the exterior stringer and 25 percent to the next stringer. | ||

| − | + | ==== 751.40.8.1.10 Other Loads ==== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''Stream Pressure''' | ||

| − | + | Stream flow pressure shall be considered only in extreme cases. The affect of flowing water on piers shall not be considered except in cases of extreme high water and when the load applied to substructure elements is greater than that which is applied by wind on substructure forces at low water elevations. | |

| − | The | + | The pressure generated by stream flow is: |

| − | <math>\, P = | + | <math>\, P = KV^2</math> |

Where: | Where: | ||

{| | {| | ||

| − | | | + | |<math>\, P</math>||= stream pressure in pounds per square foot |

| + | |- | ||

| + | |<math>\, V</math>||= design velocity of water in feet per second | ||

| + | |- | ||

| + | |<math>\, K</math>||= shape constant for the surface the water is in contact with. | ||

| + | |- | ||

| + | |<math>\, K</math>||= 1.4 for square-ended piers | ||

|- | |- | ||

| − | + | |<math>\, K</math>||= 0.7 for circular piers | |

|- | |- | ||

| − | + | |<math>\, K</math>||= 0.5 for angle-ended piers where the angle is 30 degrees or less | |

|} | |} | ||

| − | |||

| + | '''Ice Forces''' | ||

| − | + | Ice forces on piers shall be applied if they are indicated on the Bridge Memorandum. | |

| − | |||

| − | + | '''Buoyancy''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Buoyancy shall be considered when its effects are appreciable. | |

| − | |||

| − | + | '''Fatigue in Structural Steel''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Steel structures subjected to continuous reversal of loads are to be designed for fatigue loading. | |

| − | |||

| + | '''Prestressing''' | ||

| − | + | See [[751.22 P/S Concrete I Girders|EPG 751.22 P/S Concrete I Girders]]. | |

| − | |||

| − | |||

| − | + | '''Other Loads''' | |

| + | Other loads may need to be applied if they are indicated on the Bridge Memorandum. Otherwise see Structural Project Manager before applying any additional loads. | ||

| − | + | ==== 751.40.8.1.11 Group Loads ==== | |

| − | + | '''Group Loading (Service Load Design)''' | |

| − | + | Group loading combinations are: | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

:{| | :{| | ||

| − | | | + | |GP I SL||width="350pt"| <math>\, = D+L+I</math> ||100% |

| + | |- | ||

| + | |GP II SL||width="350pt"| <math>\, = D+W</math> ||125% | ||

| + | |- | ||

| + | |GP III SL||width="350pt"| <math>\, = D+L+I+0.3W+WL+LF</math> ||125% | ||

|- | |- | ||

| − | | | + | |GP IV SL||width="350pt"| <math>\, = D+L+I+T</math> ||125% |

|- | |- | ||

| − | | | + | |GP V SL||width="350pt"| <math>\, = D+W+T</math> ||140% |

|- | |- | ||

| − | | | + | |GP VI SL||width="350pt"| <math>\, = D+L+I+0.3W+WL+LF+T</math> ||140% |

|} | |} | ||

| − | + | Where: | |

| − | {| | + | {| |

| − | | | + | |<math>\, D</math>||= dead load |

| − | | | + | |- |

| + | |<math>\, L</math>||= live load | ||

| + | |- | ||

| + | |<math>\, I</math>||= live load impact | ||

| + | |- | ||

| + | |<math>\, W</math>||= wind load on structure | ||

| + | |- | ||

| + | |<math>\, WL</math>||= wind load on live load | ||

|- | |- | ||

| − | | | + | |<math>\, T</math>||= temperature force |

|- | |- | ||

| − | | | + | |<math>\, LF</math>||= longitudinal force from live load |

|} | |} | ||

| − | |||

| − | ( | + | '''Group Loading (Load Factor Design)''' |

| − | + | Group loading combinations are: | |

| − | = | + | :{| |

| − | + | |GP I LF||<math>\, = 1.3[\beta_d D+1.67 (L+I)]</math> | |

| − | + | |- | |

| − | + | |GP II LF||<math>\, = 1.3[\beta_d D+W]</math> | |

| − | + | |- | |

| − | | | + | |GP III LF||<math>\, = 1.3[\beta_d D+L+I+0.3W+WL+LF]</math> |

| + | |- | ||

| + | |GP IV LF||<math>\, = 1.3[\beta_d D+L+I+T]</math> | ||

|- | |- | ||

| − | | | + | |GP V LF||<math>\, = 1.25[\beta_d D+W+T]</math> |

|- | |- | ||

| − | | | + | |GP VI LF||<math>\, = 1.25[\beta_d D+L+I +0.3W+WL+LF+T]</math> |

|} | |} | ||

| − | |||

| − | |||

Where: | Where: | ||

{| | {| | ||

| − | |<math>\, | + | |<math>\, D</math>||= dead load |

|- | |- | ||

| − | |<math>\, L</math>||= | + | |<math>\, L</math>||= live load |

|- | |- | ||

| − | |<math>\, | + | |<math>\, I</math>||= live load impact |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | |<math>\, | + | |<math>\, W</math>||= wind load on structure |

|- | |- | ||

| − | |<math>\, | + | |<math>\, WL</math>||= wind load on live load |

|- | |- | ||

| − | |<math>\, | + | |<math>\, T</math>||= temperature force |

|- | |- | ||

| − | |<math>\, | + | |<math>\, LF</math>||= longitudinal force from live load |

|- | |- | ||

| − | |<math>\, | + | |<math>\, \beta_d</math>||= coefficient, see AASHTO Table 3.22.1A |

|} | |} | ||

| − | + | Other group loadings in AASHTO Table 3.22.1A shall be used when they apply. | |

| − | + | === 751.40.8.2 Distribution of Loads === | |

| − | ''' | + | ==== 751.40.8.2.1 Distribution of Dead Load ==== |

| + | |||

| + | '''Composite Steel or Prestressed Concrete Structures''' | ||

| + | |||

| + | The dead load applied to the girders through the slab shall be: | ||

| + | |||

| + | |||

| + | '''Dead Load 1''' | ||

| + | |||

| + | Non-composite dead loads should be distributed to girders (stringers) on the basis of continuous spans over simple supports. | ||

| + | |||

| + | '''Dead Load 2''' | ||

| + | |||

| + | Composite loads shall be distributed equally to all girders. The following are all Dead Load 2 loads: | ||

| + | :Barrier or railing | ||

| + | :Future wearing surface on slab | ||

| + | :Sidewalks | ||

| + | :Fences | ||

| + | :Protective coatings and waterproofing on slab | ||

| + | |||

| − | + | '''Concrete Slab Bridges''' | |

| + | Distribute entire dead load across full width of slab. | ||

| − | + | For longitudinal design, heavier portions of the slab may be considered as concentrated load for entry into the "Continuous Structure Analysis" computer program. | |

| − | + | For transverse bent design, consider the dead load reaction at the bent to be a uniform load across entire length of the transverse beam. | |

| + | ==== 751.40.8.2.2 Distribution of Live Load ==== | ||

| − | + | Live loading to be distributed shall be the appropriate loading shown on the Bridge Memorandum. | |

| + | Applying Live Load to Structure | ||

| − | |||

| + | '''Superstructure''' | ||

| − | + | For application of live load to superstructure, the lane width is considered 12 feet. Each design vehicle has wheel lines which are 6 feet apart and adjacent design vehicles must be separated by 4 feet. | |

| − | |||

| − | + | '''Substructure''' | |

| − | + | To produce the maximum stresses in the main carrying members of substructure elements, multiple lanes are to be loaded simultaneously. The lane width is 12 feet. Partial lanes are not to be considered. Due to the improbability of coincident maximum loading, a reduction factor is applied to the number of lanes. This reduction however, is not applied in determining the distribution of loads to the stringers. | |

| − | |||

| − | : | + | {|border="1" style="text-align:center;" cellpadding="5" align="center" |

| − | | | + | |+'''Distribution of Live Load to Beams and Girders''' |

| + | !width="150pt"|Number of Lanes||width="150pt"|Percent | ||

|- | |- | ||

| − | | | + | |one or two lanes||100 |

|- | |- | ||

| − | | | + | |three lanes||90 |

|- | |- | ||

| − | | | + | |four lanes or more||75 |

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||