903.2 Extent of Signing

Contents

- 1 903.2.1 Sign Function and Purpose (MUTCD Section 2A.01)

- 2 903.2.2 Definitions (MUTCD Section 2A.02)

- 3 903.2.3 Standardization of Application (MUTCD Section 2A.03)

- 4 903.2.4 Excessive Use of Signs (MUTCD Section 2A.04)

- 5 903.2.5 Classification of Signs (MUTCD Section 2A.05)

- 6 903.2.6 Sign Design (MUTCD Section 2A.06)

- 7 903.2.7 Types of Fabricated Signs

- 8 903.2.8 Sign ID Labels

- 9 903.2.9 Retroreflectivity and Illumination (MUTCD Section 2A.07)

- 10 903.2.10 Maintaining Minimum Retroreflectivity (MUTCD Section 2A.08)

- 11 903.2.11 Shapes (MUTCD Section 2A.09)

- 12 903.2.12 Sign Colors (MUTCD Section 2A.10)

- 13 903.2.13 Dimensions (MUTCD Section 2A.11)

- 14 903.2.14 Symbols (MUTCD Section 2A.12)

- 15 903.2.15 Word Messages (MUTCD Section 2A.13)

- 16 903.2.16 Sign Borders (MUTCD Section 2A.14)

- 17 903.2.17 Enhanced Conspicuity for Standard Signs (MUTCD Section 2A.15)

- 18 903.2.18 Standardization of Sign Location (MUTCD Section 2A.16)

- 19 903.2.19 Sign and Post Inventory and Storage

- 20 903.2.20 Sign and Post Ordering

- 21 903.2.21 Sign and Post Disposal

- 22 903.2.22 Sign Inspection

- 23 903.2.23 Emergency Response

- 24 903.2.24 Guidelines for the use of the Sign Management System (SMS)

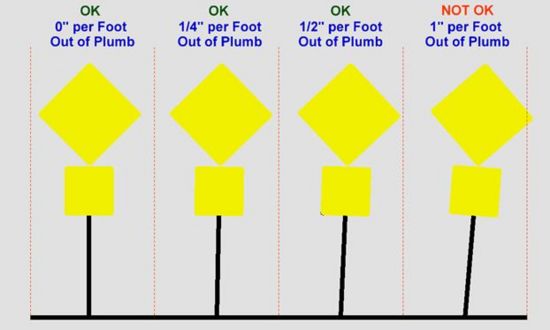

- 25 903.2.25 Design Aspects of Signing

903.2.1 Sign Function and Purpose (MUTCD Section 2A.01)

Support. The functions of signs are to regulate, warn and guide road users. Words, symbols and arrows are used to convey the messages. Signs are not typically used to confirm rules of the road. Detailed sign requirements are available for:

- 1. Regulatory signs

- 2. Warning signs

- 3. Guide signs for conventional roads

- 4. Guide signs for freeways and expressways

- 5. General information signs

- 6. General service signs

- 7. Specific service (LOGO) signs

- 8. Tourist-oriented direction signs

- 9. Changeable message signs

- 10. Recreational and cultural interest area signs

- 11. Emergency management signs

- 12. Typical applications

- 13. Sign supports.

Signing of all interstate highways is coordinated on a national basis and signing of highways other than the interstate system is coordinated on a statewide bases by MoDOT.

Standard. Because the requirements and standards for signs depend on the particular type of highway upon which they should be used, the definitions for freeway, expressway and conventional roads given in EPG 900.1.13 Definitions of Headings, Words and Phrases shall apply to all signing.

Any exceptions or requests for any sign not described in this article shall be submitted to the Highway Safety and Traffic Engineer for consideration.

903.2.2 Definitions (MUTCD Section 2A.02)

Support. Definitions and acronyms that are applicable to signs are in EPG 900.1.13 Definitions of Headings, Words and Phrases.

903.2.3 Standardization of Application (MUTCD Section 2A.03)

Support. Urban traffic conditions differ from rural conditions and in many instances signs are applied and located differently. Where pertinent and practical, this article sets forth separate recommendations for urban and rural conditions.

Guidance. Signs should be used only where justified by engineering judgment or studies. Results from traffic engineering studies of physical and traffic factors should indicate the locations where signs are deemed necessary or desirable.

Roadway geometric design and sign application should be coordinated so that signing can be effectively placed to give the road user any necessary regulatory, warning, guidance, and other information.

Standard. Each standard sign shall be displayed only for the specific purpose as prescribed in this article. Determination of the particular signs to be applied to a specific condition shall be made according to the provisions set forth in this article. Before any new highway, detour or temporary route is opened to public travel, all necessary signs shall be in place. Signs required by road conditions or restrictions shall be removed when those conditions cease to exist or the restrictions are withdrawn.

903.2.4 Excessive Use of Signs (MUTCD Section 2A.04)

Guidance. Regulatory and warning signs should be used conservatively because these signs, if used to excess, tend to lose their effectiveness. If used, route signs and directional guide signs should be used frequently because their use promotes efficient operations by informing travelers of their location.

903.2.5 Classification of Signs (MUTCD Section 2A.05)

Standard. Signs shall be defined by their function as follows:

A. Regulatory signs give notice of traffic laws or regulations.

B. Warning signs give notice of a situation that might not be readily apparent.

C. Guide signs show route designations, destinations, directions, distances, services, points of interest and other geographical, recreational, or cultural information.

The order classification of signs shall be defined as follows (refer to Fig 903.2.5):

1. First Order Signing. Signs that are installed in advance of the closest intersection or interchange where motorists turn off of the state highway system to arrive at the desired traffic generator or site. First order signing will always be on state right of way.

2. Second Order Signing. Signs that are installed in advance of the intersection or interchange where motorists turn to access the highway where the first order signing is provided. Second order signing will always be on state right of way and shall require the use of first order signing on state right of way.

3. Third Order Signing. Signs that are installed in advance of the intersection or interchange where motorists turn to access the highway where the second order signing is provided. Third order signing will always be on state right of way and shall require the use of first order and second order signing on state right of way.

Support. In general, as the “order” of signing increases, the functional classification of road stays the same or increases. For example, if first order signing is on a four-lane U.S. route, second order signing should be on another U.S. route, expressway or a freeway. In this example case, second order signing should not be placed on a two-lane lettered route.

903.2.6 Sign Design (MUTCD Section 2A.06)

Support. EPG 903 shows many typical standard signs approved for use on streets, highways, bikeways and pedestrian crossings.

In the specifications for individual signs, the general appearance of the legend, color and size are shown in the accompanying tables and illustrations, and are not always detailed in the text.

Detailed drawings of all highway signs and alphabets are provided by Central Office Highways Safety and Traffic Division.

A highway sign must be legible to those for whom it is intended and be understandable from a distance to permit a proper response. It is desirable for it to be highly visible by day and night and highly legible (e.g., adequately sized letters, symbols or arrows and a short legend for quick comprehension by a road user approaching a sign). Standardized colors and shapes are specified so that the several classes of traffic signs can be promptly recognized. Simplicity and uniformity in design, position, and application are important.

Standard. The term legend shall include all word messages and symbol and arrow designs that are intended to convey specific meanings.

Uniformity in design includes shape, color, dimensions, legends, borders and illumination or retroreflectivity.

Standardization of these designs does not preclude further improvement by minor changes in the proportion or orientation of symbols, width of borders, or layout of word messages, but all shapes and colors shall be as indicated.

All symbols shall be unmistakably similar to, or mirror images of, the adopted symbol signs, all of which are shown in EPG 903. Symbols and colors shall not be modified unless otherwise provided in the EPG. All symbols and colors for signs not shown in the EPG and SMS Sign Catalog shall follow the procedures for experimentation and change described in EPG 903.

Option. Although the standard design of symbol signs cannot be modified, the orientation of the symbol may be changed to better reflect the direction of travel, if appropriate.

Standard. Where a standard word message is applicable, the wording shall be as provided in this article.

In situations where word messages are required other than those provided in this article, the signs shall be of the same shape and color as standard signs of the same functional type.

Option. MoDOT, with the approval of Central Office Highway Safety and Traffic Division, may develop special word message signs in situations where roadway conditions make it necessary to provide road users with additional regulatory, warning or guidance information, such as when road users need to be notified of special regulations or warned about a situation that might not be readily apparent. Unlike colors that have not been assigned or symbols that have not been approved for signs, new word message signs may be used without the need for experimentation.

Standard. Expect as provided in this article and except for the Carpool Information sign, internet addresses and e-mail addresses, including domain names and uniform resource locators (URL), shall not be displayed on any sign, supplemental plaque, sign panel (including logo sign panels on Specific Service signs) or changeable message sign.

Guidance. Unless otherwise provided in this article for a specific sign or as provided in the Option below, telephone numbers with more than four characters should not be displayed on any sign, supplemental plaque, sign panel (including logo sign panels on Specific Service signs) or changeable message sign.

Option. Internet addresses, email addresses or telephone numbers with more than four characters may be displayed on signs, supplemental plaques, sign panels, and changeable message signs that are intended for viewing only by pedestrians, bicyclists, occupants of parked vehicles, or drivers of vehicles on low-speed roadways where engineering judgment indicates that an area is available for drivers to stop out of the traffic flow to read the message.

Standard. Pictographs shall not be displayed on signs except as specifically provided in this article. Pictographs shall be simple, dignified and devoid of any advertising. When used to represent a political jurisdiction (such as a county or municipal corporation) the pictograph shall be the official designation adopted by the jurisdiction. When used to represent a college or university, the pictograph shall be the official seal adopted by the institution. Pictorial representations of university or college programs shall not be permitted to be displayed on a sign

903.2.7 Types of Fabricated Signs

Support. There are two types of sign material available, structural (ST) and sheet (SH).

Sheet signs are sheet aluminum, usually one-piece units, and have several available thicknesses as indicated in the standard plans.

Structural signs are usually made of multiple extruded panels. These signs are used primarily for guide signs on expressways and freeways, but may be found on other routes on a limited basis, and are used on all overhead-mounted signs, including “LOW CLEARANCE” and exit number panels, signs greater than 6 ft. wide, and signs greater than 30 sq. ft. in area.

Extruded panels are composed of a 1 ft. tall "E" shaped aluminum substrate, assembled to a desired height and cut to a uniform width for each sign. These panels are bolted together to form the larger “blank” substrate needed for structural signs.

903.2.8 Sign ID Labels

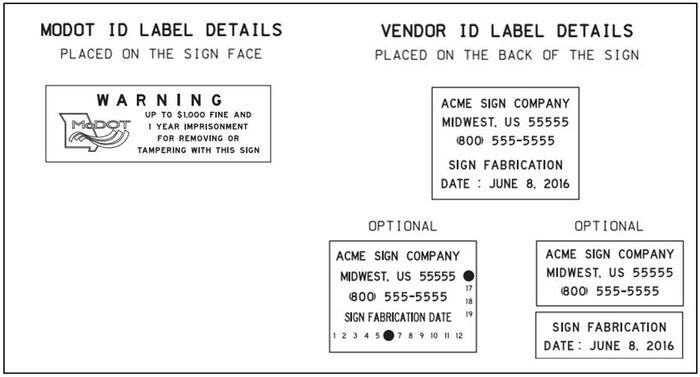

History. The display of the MoDOT ID label on the front of the sign was standard practice on all signs produced by the MoDOT Sign Production Center (SPC) up to its closing mid-2012 when MoDOT first began outsourcing the production of signs for maintenance operations. MoDOT’s sign fabrication vendors were also required to apply the traditional MoDOT ID on the front of the sign identifying it as Commission Property and listing the penalty for tampering and/or theft. The requirement to add the MoDOT ID label to signs fabricated and installed for construction projects was added to the standard plans in July of 2018.

Beginning mid-2012 with the first sign outsourcing contract, MoDOT’s sign fabrication vendors were also required to add a manufacture ID label on the back of every sign to indicate who fabricated the sign and the date the sign was produced for warranty issues. The warranty of a sign begins the day it was fabricated, not the day it is installed as sign sheeting has a limited life span (10-15 years) so this date is critical to address warranty issues. The manufacturing date can also be used by the department to help manage inventory and assure the oldest sign on the shelf are used first. July 2018 the requirement to add the manufacture ID was added to the standard plans so all signs manufactured and installed on construction projects would include this ID label as well.

Digital printing has been an option with our sign outsourcing contract since 2012. Digital printing is not currently part of our standard plans for contract/warranty issues, it was added to the sign outsourcing contract as a controlled way for the department to gain experience with the technology before adopting it as fabrication technology in our standards. With the renewal of the outsourcing contract in 2018, an additional ID label was added as a requirement for our vendor to make the identification of digitally printed signs easier. A black diamond is required to be applied to the back side of any sign the vendor chooses to fabricate using digital printing technology. While there are ways to identify digitally printed signs, the clues are very subtle, and you must be up close to the sign face to see them. The black diamond on the back side of the sign allows the department to quickly identify these signs from a distance.

The design and location of the vendor ID/fabrication date label and the MoDOT ID label can be found in Standard Plans 903 and the detail for the digital print ID label are found in the sign outsourcing contract.

Standard. Every MoDOT sign, regardless of the type or style, shall have two Identification Labels on the sign. This applies to signs manufactured for maintenance operations as well as those manufactured for construction installations. The first label is the MoDOT ID label placed on the front of the sign which identifies the sign as belonging to MoDOT and defining the penalty for tampering with the sign. The second label is the Vendor ID label placed on the back of the sign and identifies who fabricated the sign, their contact information and the date the sign was manufactured.

Support. The MoDOT ID label on the front of the sign is used to identify the sign as belonging to MoDOT. MoDOT does not sell or give away its signs, only disposing old signs as scrap (see EPG 903.2.21.1 Sign Disposal). If a person is found in possession of a sign(s) with the MoDOT ID label the sign is considered stolen and the label is utilized by law enforcement to take the necessary actions.

The Vendor ID label placed on the back of the sign is used to identify who manufactured the sign and when it was fabricated. This information is used if there is a warranty issue identified with the sign. The warranty for sign sheeting is based on the fabrication date. The fabrication date also permits MoDOT warehouse managers to identify and utilize the oldest stock signs first to assure stock is rotated.

Identification Label design and placement details are shown in Standard Plan 903.02, see Figure 903.2.8 for ID label general appearance.

903.2.9 Retroreflectivity and Illumination (MUTCD Section 2A.07)

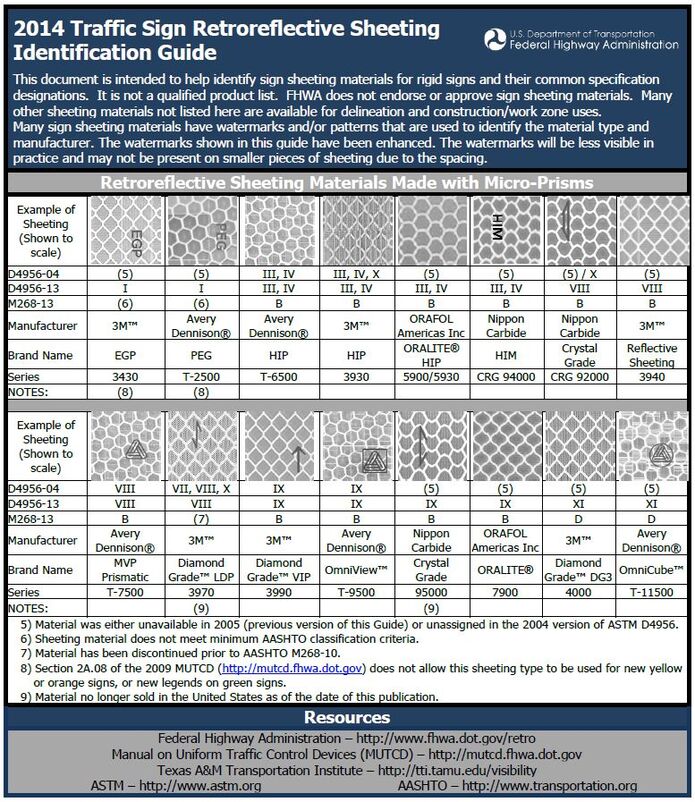

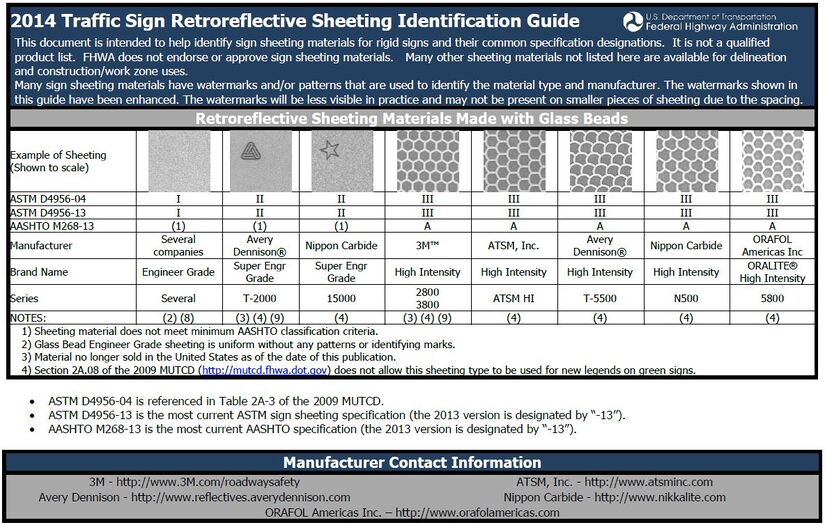

Support. There are many materials currently available for retroreflection (see Fig. 903.2.9.1 and Fig. 903.2.9.2) and various methods currently available for the illumination of signs. New materials and methods continue to emerge. New materials and methods can be evaluated as long as the signs meet the standard requirements for color, both by day and by night.

There are two types of reflective sheeting available to MoDOT:

- 1) MoDOT Type III High Intensity Prismatic (R2)

- 2) MoDOT Type VII Prismatic (R4).

For special sign designs, the type of reflective sheeting is noted on the special sign detail sheet (indicated as “BACKGROUND”).

Standard. Regulatory, warning, guide signs and object markers shall be retroreflective or illuminated to show the same shape and similar color by both day and night, unless otherwise provided in this article for a particular sign or group of signs.

The requirements for sign illumination shall not be considered to be satisfied by street or highway lighting.

Guidance. Generally, R2 sheeting should be used on all sign backgrounds. R3 sheeting should be used on all legend and symbols on guide signs.

Overhead sign installations should not be illuminated unless an engineering study shows a need for illumination, e.g. fog prone areas.

Option. Light-emitting diode (LED) units may be used individually within the legend or symbol of a standard highway sign and in the border of a standard highway sign, except for Changeable Message Signs, to improve the conspicuity, increase the legibility of sign legends and borders or provide a changeable message.

Standard. Except for STOP signs, YIELD signs, STOP/SLOW paddles or STOP/STOP paddles, neither individual LEDs nor groups of LEDs shall be placed within the background area of a sign.

If used, the LEDs shall have a maximum diameter of 0.25 in. and shall be the following colors based on the type of sign:

- 1) White or red, if used with STOP or YIELD signs.

- 2) White, if used with regulatory signs other than STOP or YIELD signs.

- 3) White or yellow, if used with warning signs.

- 4) White, if used with guide signs.

- 5) White, yellow, or orange, if used with temporary traffic control signs.

- 6) White or yellow, if used with school area signs.

If flashed, all LED units shall flash simultaneously at a rate of more than 50 and less than 60 times per minute.

The uniformity of the sign design shall be maintained without any decrease in visibility, legibility or driver comprehension during either daytime or nighttime conditions.

Option. For STOP and YIELD signs, LEDs may be placed within the border or within one border width within the background of the sign.

For STOP/SLOW paddles used by flaggers and the STOP paddles used by adult crossing guards, individual LEDs or groups of LEDs may be used.

Support. Other methods of enhancing the conspicuity of standard signs are described in EPG 903.2.17.

Information regarding the use of retroreflective material on the sign support is contained in EPG 903.2.17 Enhanced Conspicuity for Standard Signs.

903.2.10 Maintaining Minimum Retroreflectivity (MUTCD Section 2A.08)

Support. Retroreflectivity is one of several factors associated with maintaining nighttime sign visibility.

Standard. Public agencies or officials having jurisdiction shall use an assessment or management method that is designed to maintain sign retroreflectivity at or above the minimum levels in Table 903.2.10.

Table 903.2.10 Minimum Maintained Retroreflectivity Levels1

| Sign Color | Sheeting Type (ASTM D4956-04) | Additional Criteria | |||

|---|---|---|---|---|---|

| Beaded Sheeting | Prismatic Sheeting | ||||

| I | II | III | III, IV, VI, VII, VIII, IX, X | ||

| White on Green | W*; G ≥ 7 | W*; G ≥ 15 | W*; G ≥ 25 | W ≥ 250; G ≥ 25 | Overhead |

| W*; G ≥ 7 | W ≥ 120; G ≥ 15 | Post-mounted | |||

| Black on Yellow or Black on Orange | Y*; O* | Y ≥ 50; O ≥ 50 | 2 | ||

| Y*; O* | Y ≥ 75; O ≥ 75 | 3 | |||

| White on Red | W ≥ 35; R ≥ 7 | 4 | |||

| Black on White | W ≥ 50 | - | |||

| 1 The minimum maintained retroreflectivity levels shown in this table are in units of cd/lx/m2 measured at an observation angle of 0.2° and an entrance angle of -4.0°. | |||||

| 2 For text and fine symbol signs measuring at least 48 in. and for all sizes of bold symbol signs | |||||

| 3 For text and fine symbol signs measuring less than 48 in. | |||||

| 4 Minimum sign contrast ratio ≥ 3:1 (white retroreflectivity ÷ red retroreflectivity) | |||||

| * This sheeting type shall not be used for this color for this application. | |||||

| Bold Symbol Signs | |||||

| W1-1, 2 - Turn and Curve | W2-7, 8 - Double Side Roads | W11-2 - Pedestrian Crossing | |||

| W1-3, 4 - Reverse Turn and Curve | W3-1 - Stop Ahead | W11-3, 4, 16-22 - Large Animals | |||

| W1-5 - Winding Road | W3-2 - Yield Ahead | W11-5 - Farm Equipment | |||

| W1-6, 7 - Large Arrow | W3-3 - Signal Ahead | W11-6 - Snowmobile Crossing | |||

| W1-8 - Chevron | W4-1 - Merge | W11-7 - Equestrian Crossing | |||

| W1-10 - Intersection in Curve | W4-2 - Lane Ends | W11-8 - Fire Station | |||

| W1-11 - Hairpin Curve | W4-3 - Added Lane | W11-10 - Truck Crossing | |||

| W1-15 - 270 Degree Loop | W4-5 - Entering Roadway Merge | W12-1 - Double Arrow | |||

| W2-1 - Cross Road | W4-6 - Entering Roadway Added Lane | W16-5P, 6P, 7P - Pointing Arrow Plaques | |||

| W2-2, 3 - Side Road | W6-1, 2 - Divided Highway Begins and Ends | W20-7 - Flagger | |||

| W2-4, 5 - T and Y Intersection | W6-3 - Two-Way Traffic | W21-1 - Worker | |||

| W2-6 - Circular Intersection | W10-1, 2, 3, 4, 11, 12 - Grade Crossing Advance Warning | - | |||

| Fine Symbol Signs (symbol signs not listed as bold symbol signs) | |||||

| Special Cases | |||||

| W3-1 - Stop Ahead: Red retroreflectivity ≥ 7 | |||||

| W3-2 - Yield Ahead: Red retroreflectivity ≥ 7; White retroreflectivity ≥ 35 | |||||

| W3-3 - Signal Ahead: Red retroreflectivity ≥ 7; Green retroreflectivity ≥ 7 | |||||

| W3-5 - Speed Reduction: White retroreflectivity ≥ 50 | |||||

| For non-diamond shaped signs, such as W14-3 (No Passing Zone), W4-4P (Cross Traffic Does Not Stop), or W13-1P, 2, 3, 6, 7 (Speed Advisory Plaques), use the largest sign dimension to determine the proper minimum retroreflectivity level. | |||||

Support. Compliance with this provision is achieved by having a method in place and using the method to maintain the minimum levels established in Table 903.2.10. Provided that an assessment or management method is being used, an agency or official having jurisdiction would be in compliance with this provision even if there are some individual signs that do not meet the minimum retroreflectivity levels at a particular point in time.

Guidance. Except for those signs specifically identified in this provision, the following assessment or management methods should be used to maintain sign retroreflectivity:

- Visual Nighttime Inspection – The retroreflectivity of an existing sign is assessed by a trained sign inspector conducting a visual inspection from a moving vehicle during nighttime conditions. Signs that are visually identified by the inspector to have retroreflectivity below the minimum levels should be replaced.

Support. Additional information about this method is contained in EPG 903.

903.2.11 Shapes (MUTCD Section 2A.09)

Standard. Specific shapes, as shown in Table 903.2.11, shall be exclusively used for specific signs or series of signs unless otherwise provided for a particular sign or class of signs.

Table 903.2.11 Use of Sign Shapes

| Shape | Signs |

|---|---|

| Octagon | Stop* |

| Equilateral Triangle (1 point down) | Yield* |

| Circle | Grade Crossing Advance Warning* |

| Pennant Shape/Isosceles Triangle (longer axis horizontal) | No Passing* |

| Pentagon (Pointed up) | School Advance Warning Sign (squared bottom corners)* |

| Crossbuck (two rectangles in an "x" configuration) | Grade Crossing* |

| Diamond | Warning Series |

| Rectangle (including square) | Regulatory Series

Guide Series** Warning Series |

| Trapezoid | No longer used by MoDOT |

| * This sign shall be exclusively the shape shown. | |

| **Guide series includes general service, specific service, tourist-oriented directional, general information, recreation and cultural interest area, and emergency management signs. | |

903.2.12 Sign Colors (MUTCD Section 2A.10)

Standard. The colors to be used on standard signs and their specific use on these signs shall be as provided in this article. The color coordinates and values shall be as described in Tables 903.2.12.1 and 903.2.12.2 and in 23 CFR, Part 655, Subpart F, Appendix.

Support. As a quick reference, common uses of sign colors are shown in Tables 903.2.12.1 and 903.2.12.2. Color schemes on specific signs are shown in the illustrations located in each appropriate section.

Whenever white is specified in the EPG and in the standard plans as a color, it is understood to include silver-colored retroreflective coatings or elements that reflect white light. The colors coral and light blue are being reserved for uses that will be determined in the future by the FHWA. Information regarding color coding of destinations on guide signs, including community wayfinding signs, is contained in EPG 903.7.3 Color, Retroreflection, and Illumination.

Option. The approved fluorescent version of the standard red, yellow, green or orange color may be used as an alternative to the corresponding standard color.

Table 903.2.12.1 Common Uses of Sign Legend Colors

| Type of Sign | Legend | |||||||

|---|---|---|---|---|---|---|---|---|

| Black | Green | Red | White | Yellow | Orange | Fluorescent Yellow-Green | Fluorescent Pink | |

| Regulatory | X | - | X | X | - | - | - | - |

| Prohibitive | - | - | X | X | - | - | - | - |

| Permissive | - | X | - | - | - | - | - | - |

| Warning | X | - | - | - | - | - | - | - |

| Pedestrian | X | - | - | - | - | - | - | - |

| Bicycle | X | - | - | - | - | - | - | - |

| Guide | - | - | - | X | - | - | - | - |

| Interstate Route | - | - | - | X | - | - | - | - |

| State Route | X | - | - | - | - | - | - | - |

| US Route | X | - | - | - | - | - | - | - |

| County Route | - | - | - | - | X | - | - | - |

| Forest Route | - | - | - | X | - | - | - | - |

| Street Name | - | - | - | X | - | - | - | - |

| Destination | - | - | - | X | - | - | - | - |

| Reference Location | - | - | - | X | - | - | - | - |

| Information | - | - | - | X | - | - | - | - |

| Evacuation Route | - | - | - | X | - | - | - | - |

| Road User Service | - | - | - | X | - | - | - | - |

| Recreational | - | - | - | X | - | - | - | - |

| Temporary Traffic Control1 | X | - | - | - | - | - | - | - |

| Incident Management | X | - | - | - | - | - | - | - |

| School | X | - | - | - | - | - | - | - |

| ETC - Account Only | X | - | - | - | - | - | - | - |

| Changeable Message Signs1 | - | - | - | X | X | - | - | - |

| Regulatory | - | - | X2 | X | - | - | - | - |

| Warning | - | - | - | - | X | - | - | - |

| Temporary Traffic Control | - | - | - | - | X | X | - | - |

| Guide | - | - | - | X | - | - | - | - |

| Motorist Services | - | - | - | X | - | - | - | - |

| Incident Management | - | - | - | - | X | - | - | X |

| School, Pedestrian, Bicycle | - | - | - | - | X | - | X | - |

| 1 Exceptions to fluorescent orange is detailed in the standard plans. | ||||||||

| 2 Red is used only for the circle and slash or other red elements of a similar static regulatory sign. | ||||||||

Table 903.2.12.2 Common Uses of Sign Background Colors

| Type of Sign | Background | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Black | Blue | Brown | Green | Fluorescent Orange | Red | White | Purple | Flourescent Yellow | Flourescent Yellow-Green | Flourescent Pink | |

| Regulatory | X | - | - | - | - | X | X | - | - | - | - |

| Prohibitive | - | - | - | - | - | X | X | - | - | - | - |

| Permissive | - | - | - | - | - | - | X | - | - | - | - |

| Warning | - | - | - | - | - | - | - | - | X | - | - |

| Pedestrian | - | - | - | - | - | - | - | - | X | - | - |

| Bicycle | - | - | - | - | - | - | - | - | X | - | - |

| Guide | - | - | - | X | - | - | - | - | - | - | - |

| Interstate Route | - | X | - | - | - | X | - | - | - | - | - |

| State Route | - | - | - | - | - | - | X | - | - | - | - |

| US Route | - | - | - | - | - | - | X | - | - | - | - |

| County Route | - | X | - | - | - | - | - | - | - | - | - |

| Forest Route | - | - | X | - | - | - | - | - | - | - | - |

| Street Name | - | - | - | X | - | - | - | - | - | - | - |

| Destination | - | - | - | X | - | - | - | - | - | - | - |

| Reference Location | - | - | - | X | - | - | - | - | - | - | - |

| Information | - | X | - | X | - | - | - | - | - | - | - |

| Evacuation Route | - | X | - | - | - | - | - | - | - | - | - |

| Road User Service | - | X | - | - | - | - | - | - | - | - | - |

| Recreational | - | - | X | X | - | - | - | - | - | - | - |

| Temporary Traffic Control1 | - | - | - | - | X | - | - | - | - | - | - |

| Incident Management | - | - | - | - | X | - | - | - | - | - | X |

| School | - | - | - | - | - | - | - | - | - | X | - |

| ETC-Account Only | - | - | - | - | - | - | - | X3 | - | - | - |

| Changeable Message Signs1 | - | - | - | - | - | - | - | - | - | - | - |

| Regulatory | X | - | - | - | - | - | - | - | - | - | - |

| Warning | X | - | - | - | - | - | - | - | - | - | - |

| Temporary Traffic Control | X | - | - | - | - | - | - | - | - | - | - |

| Guide | X | - | - | X2 | - | - | - | - | - | - | - |

| Motorist Services | X | X2 | - | - | - | - | - | - | - | - | - |

| Incident Management | X | - | - | - | - | - | - | - | - | - | - |

| School, Pedestrian, Bicycle | X | - | - | - | - | - | - | - | - | - | - |

| 1 Exceptions to fluorescent orange is detailed in the standard plans. | |||||||||||

| 2 These alternative background colors would be provided by blue or green lighted pixels such that the entire CMS would be lighted, not just the legend. | |||||||||||

| 3 The use of the color purple on signs is restricted. | |||||||||||

903.2.13 Dimensions (MUTCD Section 2A.11)

Support. The MUTCD Standard Highway Signs and Markings book prescribes design details for up to five different sizes depending on the type of traffic facility, including bikeways. MoDOT has predetermined the sizes for all highway signs; refer to the appropriate EPG article. Smaller sizes are designed to be used on bikeways and some other off-road applications. Larger sizes are designed for use on freeways and expressways and can also be used to enhance road user safety and convenience on other facilities, especially on multi-lane divided highways and on undivided highways having five or more lanes of traffic and/or high speeds. The intermediate sizes are designed to be used on other highway types.

Standard. The sign dimensions prescribed in the sign size table in various EPG articles shall be used unless engineering judgment determines that other sizes are appropriate. Where engineering judgment determines that sizes smaller than the prescribed dimensions are appropriate for use, the sign dimensions shall not be less than the minimum dimensions specified in this article. Where engineering judgment determines that sizes that are different than the prescribed dimensions are appropriate for use, standard shapes and colors shall be used and standard proportions shall be retained as much as practical.

Guidance. Increases above the prescribed sizes should be used where greater legibility or emphasis is needed. If signs larger than the prescribed sizes are used, the overall sign dimensions should be increased in 12-inch increments.

When supplemental plaques are installed with larger sized signs, a corresponding increase in the size of the plaque and its legend should also be made. The resulting plaque size should be approximately in the same relative proportion to the larger sized sign as the conventional sized plaque is to the conventional sized sign.

903.2.14 Symbols (MUTCD Section 2A.12)

Standard. Symbol designs shall in all cases be unmistakably similar to those shown in the EPG and the MUTCD Standard Highway Signs and Markings book.

Support. New symbol designs are adopted by the Federal Highway Administration based on research evaluations to determine road user comprehension, sign conspicuity, and sign legibility.

Sometimes a change from word messages to symbols requires significant time for public education and transition. Therefore, this article sometimes includes the practice of using educational plaques to accompany new symbol signs.

Guidance. An educational plaque should accompany new warning or regulatory symbol signs not readily recognizable by the public.

Option. State and/or local highway agencies may conduct research studies to determine road user comprehension, sign conspicuity, and sign legibility.

Educational plaques may be left in place as long as they are in serviceable condition.

Guidance. Although most standard symbols are oriented facing left, mirror images of these symbols should be used where the reverse orientation might better convey to road users a direction of movement.

Standard. A symbol used for a given category of signs (regulatory, warning or guide) shall not be used for a different category of signs, except as specifically authorized in this article.

Except as provided in this article, a recreational and cultural interest area symbol shall not be used on streets or highways outside of recreational and cultural interest areas.

A recreational and cultural interest area guide sign symbol shall not be used on any regulatory or warning sign on any street, road or highway.

Option. A recreational and cultural interest area guide sign symbol may be used on a highway guide sign outside a recreational and cultural interest area to supplement a comparable word message for which there is no approved symbol for that message.

903.2.15 Word Messages (MUTCD Section 2A.13)

Standard. Except as provided in EPG 903.2.6 Sign Design, all word messages shall use standard wording and letters as shown in this article, the EPG and the MUTCD Standard Highway Signs and Markings book. Any non-standard or variable sign shall be detailed by Central Office Highway Safety and Traffic Division.

Guidance. Word messages should be as brief as possible and the lettering is to be large enough to provide the necessary legibility distance. A minimum specific ratio of 1 in. of letter height per 30 ft. of legibility distance should be used.

Abbreviations (refer to EPG 900 Traffic Control) should be kept to a minimum.

Word messages should not contain periods, apostrophes, question marks, ampersands or other punctuation or characters that are not letters, numerals or hyphens unless necessary to avoid confusion.

The solidus (slanted line or forward slash) is intended to be used for fractions only and should not be used to separate words on the same line of legend. Instead, a hyphen should be used for this purpose.

Standard. Fractions shall be displayed with the numerator and denominator diagonally arranged about the solidus (slanted line or forward slash). The overall height of the fraction is measured from the top of the numerator to the bottom of the denominator, each of which is vertically aligned with the upper and lower ends of the solidus. The overall height of the fraction shall be determined by the height of the numerals within the fraction, and shall be 1.5 times the height of an individual numeral within the fraction.

Support. The MUTCD Standard Highway Signs and Markings book contains details regarding the layouts of fractions on signs.

Guidance. When initials are used to represent an abbreviation for separate words (such as “U S” for United States route), the initials should be separated by a space of between ½ and ¾ of the letter height of the initials. When an Interstate route is displayed in text form instead of using the route shield, a hyphen should be used for clarity, such as “I-70”.

Standard. All sign lettering shall be in upper-case letters as established in the EPG and the MUTCD Standard Highway Signs and Markings book unless otherwise provided in this article for a particular sign or type of message.

The sign lettering for names of places, streets and highways shall be composed of a combination of lower-case letters with initial upper-case letters.

Support. Letter height is expressed in terms of the height of an upper-case letter. For mixed-case legends (those composed of an initial upper-case letter followed by lower-case letters), the height of the lower-case letters is derived from the specified height of the initial upper-case letter based on prescribed ratio. Letter heights for mixed-case legends might be expressed in terms of both the upper- and lower-case letters, or in terms of the initial upper-case letter alone. When the height of a lower-case letter is specified or determined from the prescribed ratio, the reference is to the nominal loop height of the letter. The term loop height refers to the portion of a lower-case letter that excludes any ascending or descending stems or tails of the letter, such as with the letters “d” or “q”. The nominal loop height is equal to the actual height of a non-rounded lower-case letter whose form does not include ascending or descending stems or tails, such as the letter “x.” The rounded portions of a lower-case letter extend slightly above and below the baselines projected from the top and bottom of such a non-rounded letter so that the appearance of a uniform letter height within a word is achieved. The actual loop height of a rounded lower-case letter is slightly greater than the nominal loop height and this additional height is excluded from the expression of the lower-case letter height.

Standard. When a mixed-case legend is used, the height of the lower-case letters shall be ¾ of the height of the initial upper-case letter.

The unique letter forms for each of the Standard Alphabet series shall not be stretched, compressed, warped or otherwise manipulated.

Support. EPG 903.7.4 Size of Signs contains information regarding the acceptable methods of modifying the length of a word for a given letter height and series.

903.2.16 Sign Borders (MUTCD Section 2A.14)

Standard. Unless otherwise provided, each sign illustrated in the EPG shall have a border of the same color as the legend, at or just inside the edge.

The corners of all sign borders shall be rounded, except for STOP signs.

Guidance. A dark border on a light background should be set in from the edge, while a light border on a dark background should extend to the edge of the sign.

903.2.17 Enhanced Conspicuity for Standard Signs (MUTCD Section 2A.15)

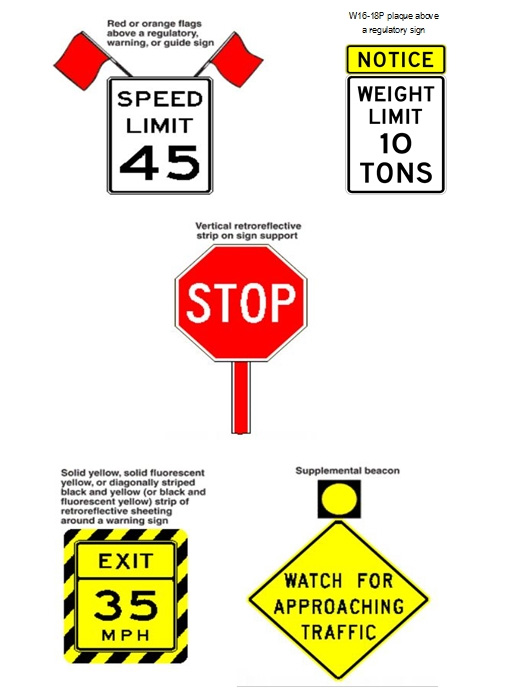

Option. Based upon engineering judgment, where the improvement of the conspicuity of a standard regulatory, warning, or guide sign is desired, any of the following methods may be used, as appropriate, to enhance the sign’s conspicuity (see Fig. 903.2.17.1):

A. Increasing the size of a standard regulatory, warning, or guide sign.

B. Doubling-up of a standard regulatory, warning, or guide sign by adding a second identical sign on the left-hand side of the roadway.

C. Adding one or more red flags (cloth or retroreflective sheeting) above a standard regulatory or warning sign, with the flags oriented so as to be at 45 degrees to the vertical.

D. Adding a solid fluorescent yellow rectangular plaque above a standard regulatory sign, with the width of the panel corresponding to the width of the standard regulatory sign. A legend of “NOTICE” may be added in black letters within the plaque determined by engineering judgment (see EPG 903.6.58 NOTICE Plaque).

E. Adding a diagonally striped black and fluorescent yellow strip of retroreflective sheeting around the perimeter of a standard warning sign.

F. Adding a warning beacon (see EPG 902 Signals) to a standard regulatory (other than a STOP or a Speed Limit sign), warning, or guide sign.

G. Adding a speed limit sign beacon (see EPG 902) to a standard Speed Limit sign.

H. Adding a stop beacon (see EPG 902) to a STOP sign.

I. Adding light emitting diode (LED) units within the symbol or legend of a sign or border of a standard regulatory, warning, or guide sign, as provided in EPG 903.2.9.

J. Adding a strip of retroreflective material to the sign support. The retroreflective strip is an aluminum sub straight 4 in. wide and 6 ft. long mounted to sign support directly below the sign. The color of the retroreflective materials shall match the background color of the sign, expect that the color of the strip for YIELD and DO NOT ENTER signs shall be red.

K. Using other methods that are specifically allowed for certain signs as described elsewhere in the EPG.

Support. Sign conspicuity improvements can also be achieved by removing non-essential and illegal signs from the right of way (see EPG 900), and by relocating signs to provide better spacing.

Standard. Strobe lights shall not be used to enhance the conspicuity of highway signs.

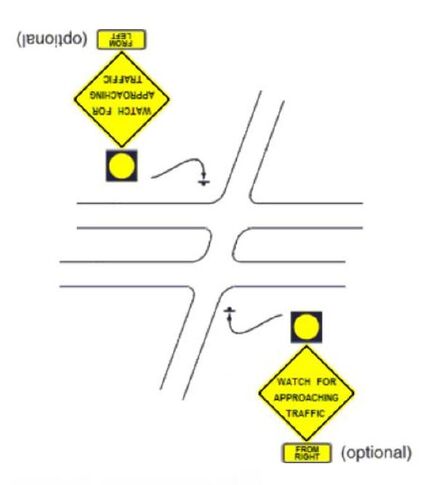

If installed for improvement of the conspicuity of intersection signing, the WATCH FOR APPROACHING TRAFFIC (special) sign shall be used, see Fig. 903.2.17.2.

If plaques are used, they shall be installed below the main sign, up to two plaques.

A warning beacon shall be set on steady flash if a problem would occur with the beacon.

If a strip of retroreflective material is used on the sign support, it shall be at least 4 inches wide, it shall be placed for the full length of the support from the sign to within 4 feet above the edge of the roadway, and its color shall match the background color of the sign, except that the color of the strip for the YIELD and DO NOT ENTER signs shall be red.

Option. The FROM LEFT or FROM RIGHT (special) plaque may be used.

Guidance. Routine inspection of the beacon should be done and determined by the district.

903.2.18 Standardization of Sign Location (MUTCD Section 2A.16)

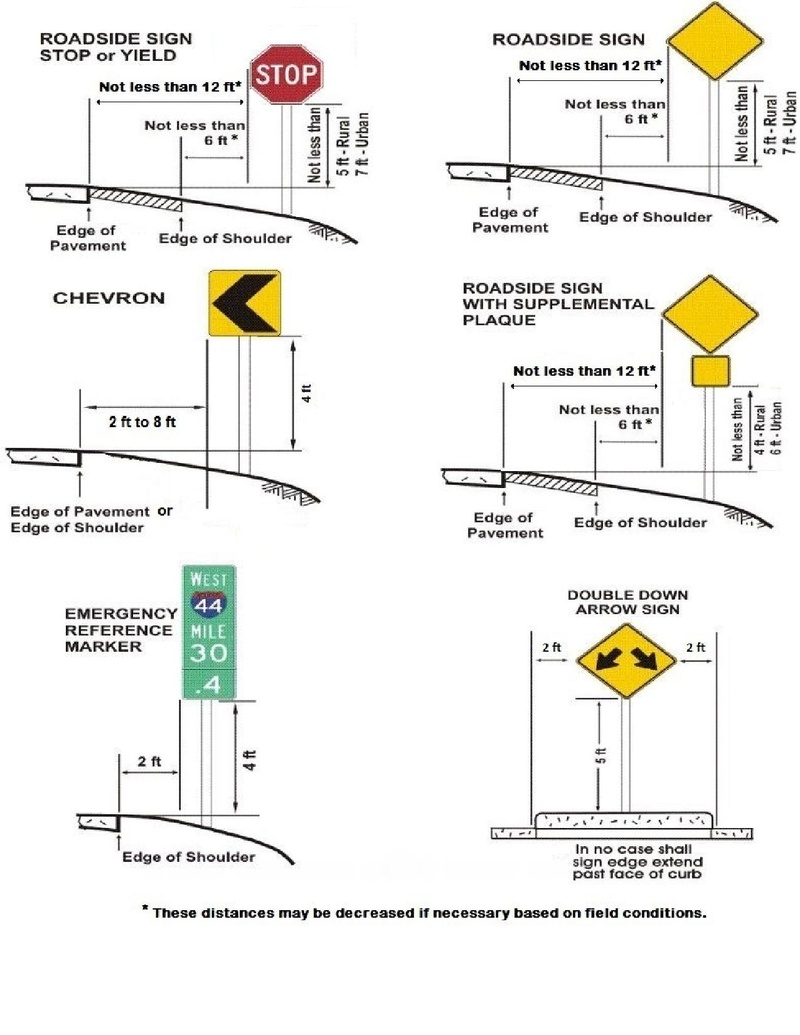

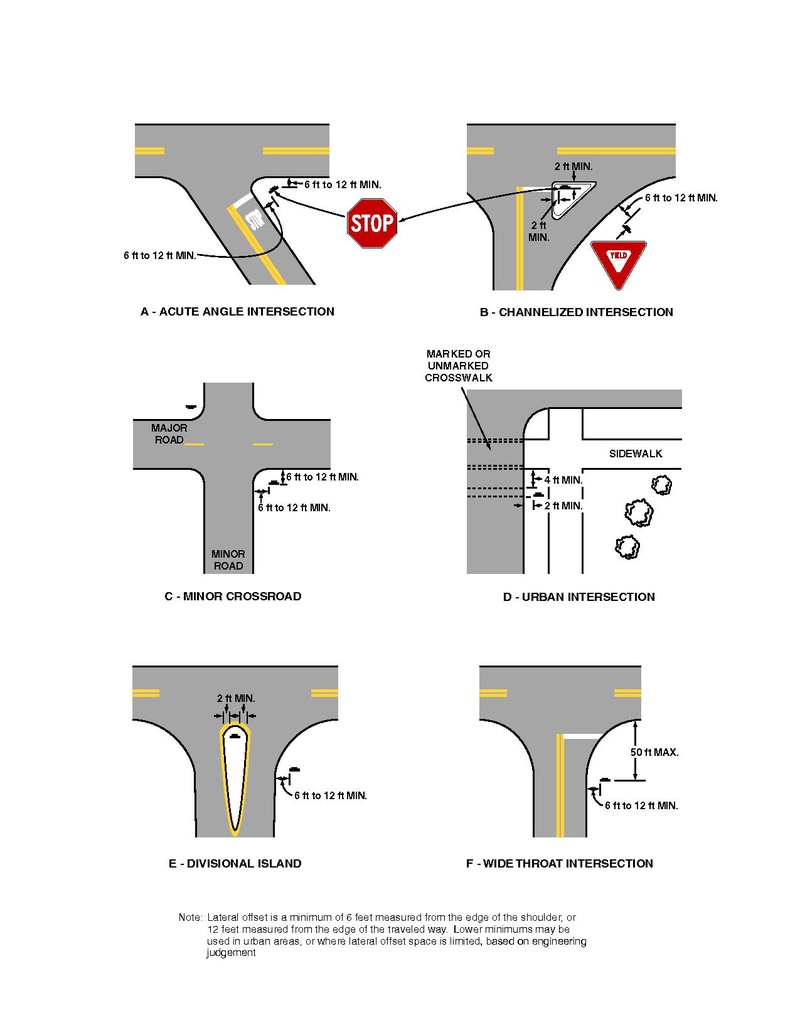

Support. Standardization of position cannot always be attained in practice. Examples of heights and lateral locations of signs for typical installations are illustrated in Fig. 903.2.18.1 and examples of locations for typical signs at intersections are illustrated in Fig. 903.2.18.2.

EPG 903.5, EPG 903.6 and EPG 903.7 contain provisions regarding the application of regulatory, warning and conventional guide signs, respectively.

Standard. Signs requiring separate decisions by the traveler shall be spaced sufficiently far apart for the appropriate decisions to be made. One of the factors considered when determining the appropriate spacing shall be the posted or 85th-percentile speed.

Guidance. Mainline signs on freeways and expressways should be visible a minimum of 800 feet and signs on conventional roads should be visible a minimum of 200 feet (minimum sign spacing in the MUTCD sections 2D and 2E). These distances should be considered when determining spacing between signs and when evaluating sign legibility during sign inspections. When these minimum sign spacing distances are not achievable, engineering judgement should be used to determine if the sign can be relocated to improve visibility, provide advance signing or determine if a reduced sign spacing distance is appropriate.

Signs should be located on the right-hand side of the roadway where they are easily recognized and understood by travelers. Signs in other locations should be considered only as supplementary to signs in the normal locations, except as otherwise provided in this article.

Signs should be individually installed on separate posts or mountings except where:

- A. One sign supplements another, or

- B. Route or directional signs are grouped to clarify information to motorists, or

- C. Regulatory signs that do not conflict with each other are grouped, such as turn prohibition signs posted with ONE WAY signs or a parking regulation sign posted with a speed limit sign.

- D. Street name signs are posted with a STOP or YIELD sign.

Signs should be located so that they:

- A. On right of way, are installed on a breakaway assembly, regardless of where they are located;

- B. Optimize nighttime visibility;

- C. Minimize the effects of mud splatter and debris;

- D. Do not obscure each other;

- E. Do not obscure the sight distance to approaching vehicles on the major street for drivers who are stopped on minor-street approaches;

- F. Are not hidden from view; and

- G. Do not block view of intersection.

Support. The clear zone is the roadside border area measured from the edge of the pavement that is available for the safe use by errant vehicles as determined according to the EPG. The width of the clear zone depends on traffic volumes, speeds and roadside geometry.

Guidance. Because of increased traffic, an order of sign installation priority should be established to provide travelers with regulatory, warning, and guidance information.

Support. An order of priority is especially critical where space is limited for sign installation and there is a demand for several different types of signs. Overloading motorists with too much information is not desirable.

Guidance. Because regulatory and warning information is more critical to travelers than guidance information, regulatory and warning signing whose location is critical should be displayed rather than guide signing in cases where conflicts occur. Community wayfinding and acknowledgment guide signs should have a lower priority as to placement than other guide signs. Information of a lesser critical nature should be moved to less critical locations or omitted.

Option. Signs may be placed on median islands or on the left-hand side of the road under some circumstances, such as on curves to the right. A supplementary sign located on the left-hand side of the roadway may be used on a multi-lane road where traffic in a lane to the right might obstruct the view to the right.

Guidance. In urban areas where crosswalks exist, signs should not be placed within 4 ft. in advance of the crosswalk.

903.2.19 Sign and Post Inventory and Storage

Support. MoDOT allocates millions of dollars each year to maintain almost 700,000 signs installed along its highways. To maintain these signs in an efficient and timely manner, appropriate sign and post inventories need to be maintained. Sign inventories need to include Priority 1 and Priority 2 signs and may include other high use signs to make ordering and request fulfilment more efficient.

To maintain the appropriate inventory level of priority and high usage signs, the inventory levels need to be based on the historical usage of each sign by the district, a level which will allow timely repairs to signs in the field, yet not represent a waste of resources with an overabundance of inventory or signs that exceed their shelf-life.

Maintaining appropriate inventory levels for each sign post is also critical for timely sign maintenance. Each post type has different lead times which must be accounted for when determining appropriate inventory levels. Pipe and Wide Flange posts are MoDOT specific designs and must be fabricated when ordered which results in very long lead times for delivery. Other post types tend to be more readily available and in stock with our vendors resulting in a shorter delivery time, such as PSST and U-channel posts.

Guidance. Given the importance of maintaining an inventory of signs and posts and the value of this resource, districts should consider assigning the duties of warehouse management to an individual, or individuals. Typical duties of an individual(s) who manages these inventories can include ordering signs and posts, receiving and inspecting signs from vendors, maintaining the district warehouse inventory of signs and posts and processing sign and post needs from field crews. This may also include delivering these materials to some or all remote locations within a district. Without proper management, inventories can easily grow out of control or be insufficient to meet the needs of the field crews.

Standard. Districts shall determine their maximum inventory levels by using the sign and post usage reports, running each report at the beginning of each fiscal year. The reports will identify the maximum and minimum recommended levels for each sign and post commodity. These reports will calculate the values based on the average usage over the previous 36 months from the date the reports are run. The average of the past 36 months will flatten spikes in any given year which will result in maximum levels being too high or low.

903.2.19.1 Supply Items (Non-Inventory Items)

Support. There are many components used to install and maintain signs, these can be broken down into two categories; inventory items and supplies, see Table 903.2.19.1. Supplies are those items that are not individually inventoried and are generally smaller items purchased in larger quantities. These items will not have commodity codes associated with them as Inventory Items typically do. Guidance for inventory items can be found in subsequent sections of this article.

| Inventory Items | Supply Items |

|---|---|

| Wide Flange Post / Stub | Base Bolts / Washers / Nuts / Concrete Anchors |

| Pipe Post / Stub | Bolt Retainer Plates |

| PSST Post / Anchor (7 gauge & 12 gauge) | Brass Shims |

| Channel Post / Stub | Dent Breakaway Bolts |

| Wood Post | Wide Flange Breakaway Bolts / Washers / Nuts |

| PSST 2.25" Insert (72" X 2.25") | PSST Post Splice (12" X 1.75" and 2.25" PSST) |

| PSST Surface Mount Bases (for 2" and 2.5") | Aluminum Backer Bar |

| PSST Redi-Torque Assembly (for 2.5") | Slip Base Parts (top only, wedge, replacement bolt) |

| PSST Kleen Break Assemblies (for 2") | Wood Post Clamps |

| PSST Snap n Safe Couplers (for 2" and 2.5") | Pipe Post Clamps |

| Pipe Post Caps | |

| PSST Bolts / Washers / Nuts | |

| Nylon Sign Washers | |

| Ready-Mix Concrete | |

| Bags of Concrete | |

| Pole Setting Foam |

Guidance. While supplies are not tracked and counted as inventory, these items should still be managed in an efficient manner. Like inventoried items, the quantity of any given supply should be based on the district’s average 36-month usage. The maximum inventory level for each supply item should not exceed the average 3-month usage rate and the minimum inventory level should be based on the time it takes to order and receive the supply item.

903.2.19.2 Sign Inventory

Support. Signs have a shelf-life and a warranty; the warranty begins the day the sign is fabricated. All signs have a manufacturer’s ID decal on the back of the sign which includes the date of manufacturing that can be used to determine the age of signs in inventory.

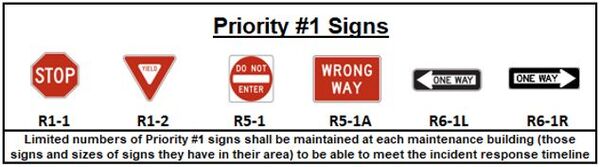

The need for inventory of signs is based on the priorities assigned to sign replacement and maintenance and is focused on Priority 1 and Priority 2 signs. These are signs which are critical to the safety of the roadway and need to be readily available to repair or replace damaged or missing signs in a short period of time, see EPG 903.2.23 Emergency Response for lists of priority signs and the required repair time. Priority 1 and Priority 2 sign repairs cannot wait for a sign to be ordered, manufactured and shipped resulting in the need to keep a reasonable number of each type of sign on hand to fulfill these work orders.

Standard. Priority 1 and Priority 2 signs shall be maintained in inventory to facilitate timely repairs. For Priority 2 signs with usage less than 1 per year, a single sign shall be inventoried, or a 7-day accelerated order shall be used to acquire the sign when needed.

Inventory levels for signs shall be based on the district’s average 36-month usage report for all sign commodities. The maximum inventory level for each sign commodity shall not exceed the average 3-month usage rate. The minimum inventory should be no less than your average usage in one month.

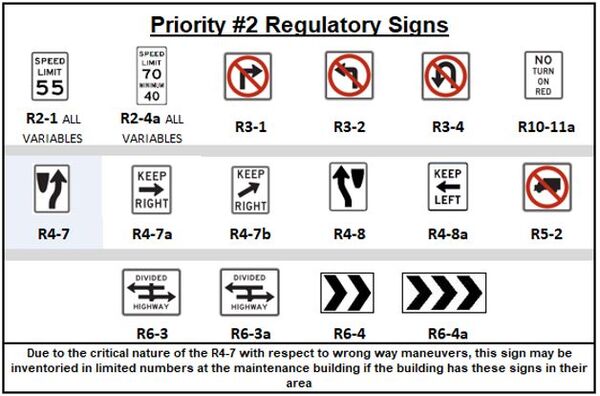

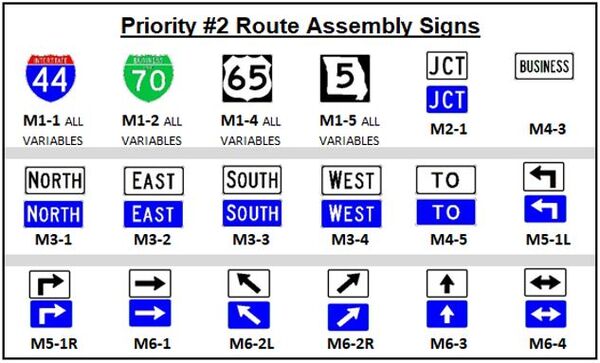

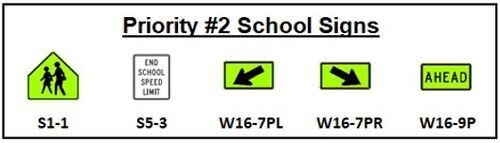

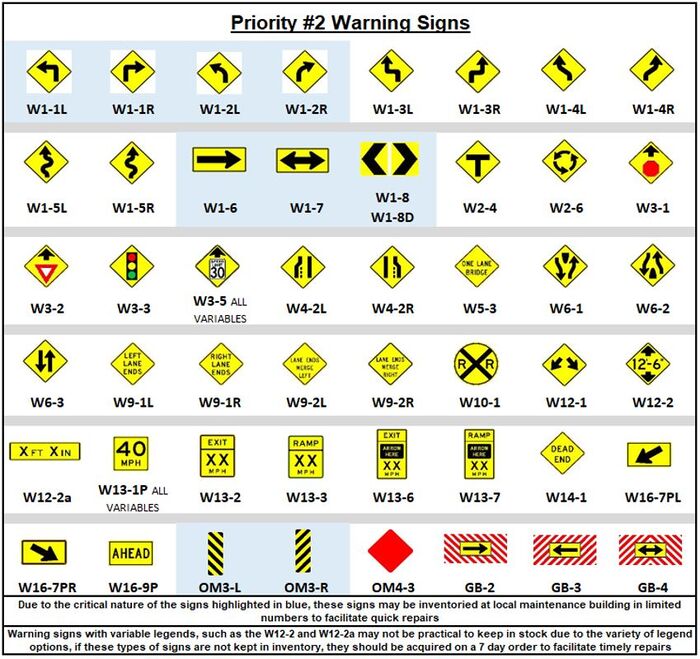

The maximum inventory levels for signs are maintained at the district warehouse. Local maintenance buildings shall keep small inventories of Priority 1 signs and may keep a small inventory of select Priority 2 signs (see Figures 903.2.19.2.1 thru 903.2.19.2.2.5).

As signs are pulled from MoDOT inventories, the oldest signs shall be used first to ensure the department gets the maximum life from any given sign and to ensure inventory doesn’t exceed its shelf-life. The age of the sign is determined by the manufacturing date found on the manufacture’s ID on the back of the sign.

Option. Maximum inventory levels of signs may exceed the 3-month usage when signs are ordered to fulfill the needs of specific work orders generated by annual sign log inspections. To avoid an overabundance of signs at a building and to avoid overloading our vendors, orders need to be submitted at a rate that closely matches the crew’s ability to install the signs once they are delivered. These temporary inventory levels must be installed for the locations they were ordered for in less than a year.

Guidance. Minimum inventory levels for each sign should be equal to the average 1-month usage rate. This would be the quantity of signs expected to be used during the time it takes the vendor to resupply the inventory with a new order.

| Sign Priority | Inventory Levels* | Kept in Stock | |

|---|---|---|---|

| Max | Min | ||

| Priority 1 | 3 months | 1 month | Required |

| Priority 2 | 3 months | 1 month | Required |

| Priority 3 high usage | 3 months | 1 month | Optional |

| Priority 3 low usage | 0 | 0 | Not Recommended |

| * Inventory levels of each sign number are based on the 36-month average usage for the district | |||

903.2.19.3 Sign Storage and Handling

Support. Proper storage and handling of highway signs before and during installation is critical to achieve the maximum sign life and effectiveness. Sign sheeting is easily damaged by impacts, abrasions, weight, heat and moisture before installation. Sign sheeting has a minimum of a 10-year warranty from the date of fabrication, however, this warranty is void if the sheeting is damaged due to improper storage or handling.

Standard. Flat sheet signs shall be stored indoors in a cool and dry environment with the signs being placed in the racks on their edge. If for some reason signs are wet in storage or shipping, they shall be removed from any packaging immediately, separated and placed on their vertical edge so they can air dry.

Support. Extruded panel signs should be stored indoors in a cool and dry location, however, given the size of these signs this is not always possible. If extruded panel must be stored outdoors, they need to be kept dry. Ideally, signs would be removed from their packaging, assembled (in whole or in pieces) and temporarily mounted to posts or an A-frame trailer so water can shed off of the sign face and air dry as if they were installed permanently.

During transport, flat sheet signs should be carried on their vertical edge and both flat sheet and extruded signs (and pieces of signs) should be secured so the sign sheeting side of the signs do not rub on one another or against the vehicles causing damage.

903.2.19.4 Post Inventory

Support. Unlike signs, sign posts do not have a shelf-life. While they can be stored indefinitely without loss of integrity, it is still critical to properly manage inventory levels to ensure the best use of MoDOT resources.

| Post Type | Post Size | Inventory Levels | Kept in Stock | |

|---|---|---|---|---|

| Max | Min* | |||

| Wood | 4x4 | 3 months | 0 | Optional |

| 4x6 | 3 months | 0 | Optional | |

| U-Channel | 3 lb/ft | 3 months | 2 months | Required |

| PSST | 2x2 | 3 months | 1.5 months | Required |

| 2.5x2.5 | 3 months | 1.5 months | Required | |

| Pipe*** | 2.5" ID | 6 months | 3 months or 2 posts | Recommended** |

| 3" ID | 6 months | 3 months or 2 posts | Recommended** | |

| 4" ID | 6 months | 3 months or 2 posts | Recommended** | |

| Wide Flange*** | #1 | 6 months | 3 months or 3 posts | Recommended** |

| #2 | 6 months | 3 months or 3 posts | Recommended** | |

| #3 | 6 months | 3 months or 3 posts | Recommended** | |

| #4 | 6 months | 3 months or 3 posts | Recommended** | |

| #5 | 6 months | 3 months or 3 posts | Recommended** | |

| #6 | 6 months | 3 months or 3 posts | Recommended** | |

| * Minimum inventory levels based on contract delivery period of each post type | ||||

| ** Given the long lead times for acquiring these types of posts, it is recommended districts keep the minimum levels indicated unless a size is extremely rarely used in a district. If one set of posts are retained as a minimum, the longest length that may be needed should be what is retained. | ||||

| *** If a district has inventory greater than the maximum listed, the posts shall be retained, and their availability made known to the rest of the state. They shall not be scrapped unless they no longer meet MoDOT specifications. | ||||

903.2.19.4.1 Wood, U-Channel and PSST Posts

Standard. Inventory levels for these posts shall be based on the district’s average 36-month usage report for all post commodities. The maximum inventory level for each U-Channel and PSST post commodity shall not exceed the average 3-month usage rate. Minimum inventory levels for these posts should typically equal the average number of posts used during the length of time it takes to order and receive new posts.

Wood posts shall be purchased on an as needed basis from local sources not only to minimize inventory levels, but to minimize the chances of waste due to the tendency of a wood post to warp and twist over time.

Option. Maximum inventory levels of sign posts may exceed 3-month usage when posts are ordered to fulfill the needs of specific work orders generated by annual sign log inspections. To avoid an overabundance of sign posts at a building and to avoid overloading our vendors, orders need to be submitted at a rate that closely matches the crew’s ability to install signs and posts once they are delivered. These temporary inventory levels must be installed for the locations they were ordered for in less than a year.

903.2.19.4.2 Pipe and Wide Flange (I-Beam) Posts

Support. Pipe and Wide Flange posts are unique in that they are far more expensive to purchase compared to other MoDOT standard posts. These designs are specific to MoDOT so a vendor must fabricate these post types as the orders are received resulting in long lead times for delivery. The usage rates for these posts, especially for certain sizes of posts, are not as regular as other types of posts. As a result, an inventory based on the 36-month average usage may not result in the proper number of posts in inventory.

Each post type comes in a variety of different lengths and each length is individually inventoried. This variety of inventoried lengths was established to provide posts in inventory that would be as close to the length needed to reduce the amount of waste as posts were trimmed to the proper length. This method was established when post usage on all posts was much higher and inventory level management was not as critical.

Standard. Inventory levels for these posts shall be based on the district’s average 36-month usage report for all post commodities. The maximum inventory level for each Pipe and Wide Flange post commodity shall not exceed the average 6-month usage rate.

Guidance. Minimum inventory levels for these posts should typically equal the average number of posts used during the length of time it takes to order and receive new posts. However, due to the long delivery lead times for Pipe and Wide Flange posts, the minimum quantity for these posts typically should not be zero unless a size of post is very rarely used in the district. In these cases, a minimum quantity of 2-3 should be kept on hand to repair or install one sign for emergency situations.

For low usage post types, such as structural #6 Wide Flange posts, it is important to have posts on hand for unexpected needs; however, maintaining a minimum inventory of all available sizes is not recommended. For these low usage posts, the longest post length that may be needed in the district is what should be inventoried, and any actual length needed can be cut from this length. While this will likely generate greater waste as more posts may be cut off to size the post for the need, this waste is preferred over excessive numbers of posts of various lengths on inventory.

903.2.19.4.3 Post Storage and Handling

Support. Unlike signs, posts do not have a shelf life and can be stored indefinitely without loss of integrity if stored properly.

Standard. Sign posts shall be stored up off the ground to avoid corrosion that would result from ground contact.

Guidance. If the galvanized coating of the posts is damaged, it should be patched using a zinc-based product to prevent corrosion.

903.2.20 Sign and Post Ordering

Support. Ordering practices have a direct impact on pricing and vendor participation in our contracts. The primary factor is the quantity of materials ordered at one time and more specifically placing small orders for items which are expensive to ship like sign posts and signs. Shipping costs per item for large items tends to decrease as quantities increase. As an example, the shipping costs for 20 posts on a flatbed truck is the same as it is for a shipment of 200 posts, but if posts are ordered in quantities of 20, the cost of each post is higher as the shipping costs are associated to a smaller number of posts.

903.2.20.1 Sign Ordering

Support. MoDOT began outsourcing the fabrication of signs for maintenance operations and closed its Sign Production Center in 2012. This change also incorporated many modifications to the way MoDOT did business. MoDOT eliminated many department specific sign designs and adopted federal sign standards. The funding for the acquisition of signs was transferred from central office to the districts and the sign ordering practices were structured to better accommodate acquiring signs through a 3rd party vendor.

MoDOT’s sign outsourcing contract is set up on a weekly cycle format. Orders are submitted to the vendor on Wednesday of each week with normal delivery time being 21 calendar days starting on the next day (Thursday). There are accelerated delivery timelines for special needs, 7-day and 14-day deliveries, that can be submitted any day of the week. There is also a 36-hour rush order; however, this is only utilized for critical needs and its use must be approved by Highway Safety and Traffic. Pricing for signs in this contract is by square foot and the contract is separated into three categories of flat sheet signs, extruded panel signs and a unique category that contains items such as stop/slow paddles and delineators. The way sign orders are assembled has a dramatic impact on the amount of time it takes to process them once submitted. The following guidance was developed to help stream-line the process and control the overall cost of the signs MoDOT purchases.

Guidance. A district sign warehouse inventory should fill a large portion of sign requests for Priority 1 and Priority 2 signs as well as high usage signs. Requests for signs not kept in inventory should be consolidated and added to a weekly sign order. Replenishment of inventory should also be added to the weekly sign order. Weekly orders should be submitted as a normal 21-day order with 7-day and 14-day accelerated orders being reserved for special cases where a sign (or small number of signs) must be received more quickly. These accelerated orders need to be used sparingly as it places an extra burden on our vendor that can affect their ability to fulfill orders for the rest of the state if overused.

Sign orders are established to match the contract format so like sign types are contained on a given order resulting in one order per week for:

- Flat sheet signs

- o Adopt-a-Highway (as its own flat sheet order)

- Structural signs

- Unique signs.

If the number of sign requests per sign order exceeds the maximum limit of 99 lines, more than one weekly sign order shall be submitted for that sign type.

Individual sign requests for like sign numbers and sizes should be pulled from stock, and a consolidated sign request should be submitted to replenish stock. This minimizes the time it takes for Highway Safety and Traffic Division to review and process sign orders, but more importantly, makes it more efficient for our vendor to determine what signs need to be fabricated for the state each week.

The weekly sign ordering process takes place as follows:

- Thursday through Tuesday – District warehouses receive and process sign requests from the field, filling requests from stock when possible and adding others to the list of signs to add to the weekly vendor order in the Sign Management System (SMS).

- Tuesday – All vendor orders for the week need to be submitted Tuesday afternoon and no later than 5:00 pm so they will interface with SAM II for the creation of purchase orders that night. The vendor orders may be submitted earlier if employees are out of the office on Tuesday, but this will count toward the districts one purchase order per sign type for the week.

- Wednesday – All purchase orders should be submitted to Central Office Highway Safety and Traffic Division by 10 am.

- Expedited purchase orders – 36-hour rush, 7 day, and 14-day orders may be sent to Central Office Highway Safety and Traffic Division any weekday. A district should give additional notice by phone or email of these orders, preferably in advance when the sign is first requested.

- Receiving Signs – The district has five (5) business days after receipt of order (ARO) to notify the contractor of any visible damage or specification compliance issues. After the five (5) working days the contractor will still be responsible for correcting any issues relating to specifications, quantity and quality, but liquidated damages will no longer be applicable. The contractor will not be responsible to correct any damages not identified within the first five (5) business after receipt of the signs. The contractor shall replace any sign(s) that fails inspection within the original delivery timeframe. The contractor shall understand and agree any replacement sign(s) that is shipped beyond the original delivery timeframe shall be subject to liquidated damages.

- Liquidated Damages – While it is not MoDOT’s intent to negatively impact our vendors by imposing liquidated damages, this contractual condition does ensure MoDOT’s orders receive priority.

- Shipping Locations – To keep sign costs as low as possible, the MoDOT shipping locations have been limited to the sign warehouses in NW, NE, KC, CD and SL only. Due to the geographical size of SW and SE districts, each has a secondary delivery location at their regional offices in Joplin and Willow Springs. While it would be more efficient for MoDOT to have signs shipped directly to each maintenance building, the shipping costs would be so extreme it would drive the cost of signs beyond acceptable limits.

903.2.20.2 Post Ordering

Guidance. Post orders should incorporate quantities to replenish inventories at the district warehouse location as well as any additional needs at the various maintenance buildings to make these orders as cost effective as possible.

Standard. Due to the higher cost, long lead times for acquisition and sometimes erratic usage of Pipe and Wide Flange posts, districts shall first determine if the posts they need are available in any other district before ordering. At the time this guidance was drafted, there was excess inventory in the state for Pipe and Wide Flange posts which needed to be utilized.

Option. Once the state-wide inventory levels of Pipe and Wide Flange posts are normalized and the excess inventory is used, the practice of looking at state-wide inventories of Pipe and Wide Flange posts may be used to fulfill the need for these posts if the posts are needed more quickly than the vendor can supply them.

903.2.21 Sign and Post Disposal

Support. Signs and Posts are state property and as such when no longer needed due to being obsolete, damaged or reaching the end of their service life need to be disposed of through the competitive bid process like any other MoDOT property.

903.2.21.1 Sign Disposal

History. During the operations of MoDOT’s Sign Production Center (SPC), old signs were shipped to the Moberly Correctional Center where they were sorted and stored until the SPC submitted a request. Once the request was received, the prison would clean and straighten the appropriate sign blanks from the reclaimed inventory and ship to the SPC for production. At the peak, 75% of the sign the SPC produced were on these reclaimed sign blanks. When sign production was first outsourced, the use of reclaimed sign blanks was investigated; however, the shipping cost to the prison and then to the vendor was cost prohibitive, making the use of reclaimed sign blanks more expensive than the use of new aluminum. As a result, old signs are now sold for scrap at the end of their service life.

Support. All signs, including those that have reached the end of their service life or signs in warehouses which have become obsolete, are state property and must be disposed of as scrap. MoDOT’s policy does not permit the transfer ownership of its signs, other than selling signs as scrap, to other entities. This makes prosecution for sign theft easy as anyone who is in the possession of one of these signs could not have legally acquired it.

Standard. When signs are removed from the field or warehouse inventory, they shall be collected and sold as scrap following General Services policies for the disposal of state materials. The disposal of signs that are traffic control devices, whose use is regulated by state and federal law, includes an additional step. Any traffic control devices which are taken out of service and scrapped (signs, signal heads, changeable message signs, etc.) must be sold using the GS-23 Bill of Sale of Traffic Control Devices. The GS-23 contains a legal statement the purchaser of these materials is prohibited from reselling them in the form of traffic control devices, and reads:

- (3) TRAFFIC CONTROL DEVICES TO BE USED AS SCRAP ONLY: The Buyer shall use traffic control devices purchased under this Bill of Sale for purposes other than traffic control unless the buyer is a political subdivision of the State of Missouri or authorized contractor. These materials shall not be sold or distributed in their current forms as traffic control devices. In the event the Buyer chooses to sell said traffic control devices, the Buyer shall, prior to any sale, permanently deface or otherwise disable the traffic control devices to impede their use in current form as traffic control devices. Buyer also acknowledges that the Manual on Uniform Traffic Control Devices, 23 CFR 655, 23 USC 109(d) and 23 USC 402(a) apply to the use of traffic control devices and do not allow the presentation of advertising messages or other messages unrelated to traffic control on a traffic control device. Buyer also acknowledges that Buyer has read and understands Missouri Statute 304.321, attached.

When sign inventory levels are managed correctly, there is typically no need to dispose of new/unused signs unless they are damaged. However, if guidance from Highway Safety and Traffic Division is given to purge certain signs from inventory before use, these signs shall be disposed of in the same manner as used signs.

903.2.21.2 Post Disposal

Support. Unlike signs, posts do not have a shelf-life so they can be stored indefinitely until needed.

Standard. The only time unused sign posts, stubs, hardware, etc. shall be sold as scrap is if those materials have been identified as no longer meeting state specifications. These materials shall remain in inventory until the district, or another district, is able to utilize them. Used and damaged sign posts, stubs and hardware shall be disposed of as scrap following standard GS procedures.

903.2.22 Sign Inspection

Support. Sign inspection is critical to the maintenance of MoDOT’s highway signs. The process assures we identify deficient signs, establishes the sign maintenance program for the year and is the department’s means to complying with federal sign maintenance standards.

Night time visual sign inspections are used to evaluate MoDOT’s signs as sign visibility is the most critical and difficult to achieve during dark conditions. Signs become more critical at night as other visual cues a driver needs are going to fade away in the dark (trees, ditches, etc.). Night time crashes are also typically higher compared to daytime crashes making highly visible signs a key tool to help reduce crashes.

| Training Document |

| Sign Log Inspection Guidance |

Inspectors need to view the signs during the inspection from the perspective of the motorist, from the driver seat, traveling in the lane and looking at the signs from the distances a driver needs to see the sign from to make appropriate decisions. In addition to the guidance which follows, the Sign Log Inspection Guidance Training PowerPoint walks an inspector through the process and provides photographic examples of what to look for during an inspection.

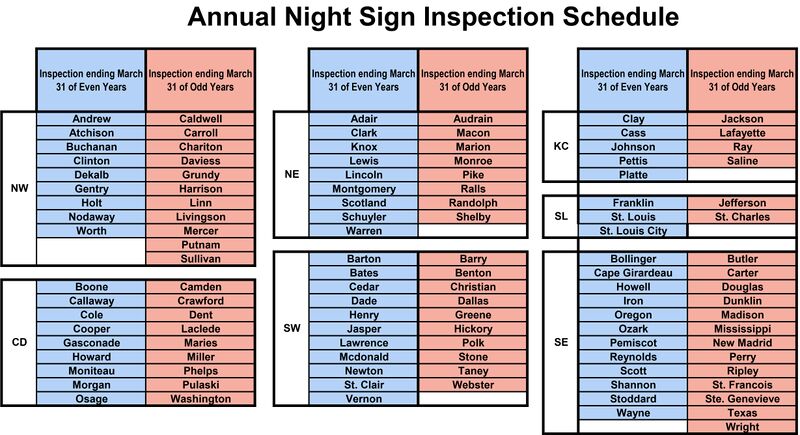

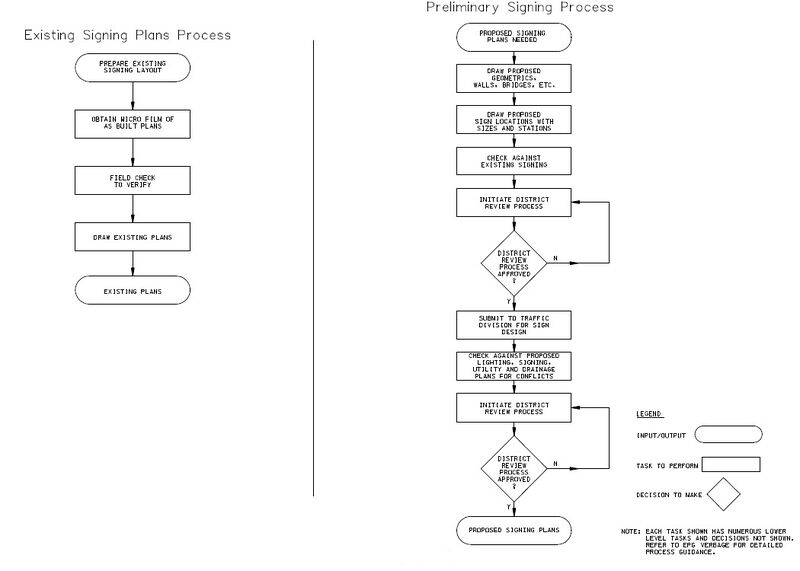

Standard. All MoDOT signs shall be inspected every other year based on the county they are located in. Figure 903.2.22.1, and Table 903.2.22 for the county inspection schedule, indicates which counties shall be inspected in the even and odd year cycles.

Options. There are sign deficiencies which can be easily identified during normal day time operations outside the annual night time inspection period. Typical deficiencies that are easy to identify during the day can include:

- Vegetation growing in front of signs

- Signs which are leaning and out of plumb or twisted away from traffic

- Signs mounted on the incorrect post or have the incorrect number of posts

- Missing breakaway devices or the breakaway device is incorrectly assembled

- o These are deficiencies which cannot be identified at night but can represent serious safety issues for the public.

- Sign faces which have faded colors, pealing sign legend or sign sheeting

- Signs which have been physically damaged by impacts, gun shots, etc.

Correcting deficiencies such as these outside the annual night time inspection will result in fewer deficiencies identified during the inspection and will result in the inspection taking less time to complete.

Standard. Annual night sign log inspections shall follow these basic criteria:

- Signs shall be inspected 1 hour after sunset and at least 1 hour prior to sunrise to ensure complete darkness

- Signs shall be inspected with low beam headlights

- Keep interior lights off so eyes are acclimated to darkness (dim lights are OK to illuminate computer keyboard)

- Once frost and/or dew begin to settle on the signs (thus affecting retroreflectivity), discontinue inspections

- Signs on side streets shall be inspected by driving the side street approaching the sign

- The sign legend and background colors should be recognizable both day and night (for example, a guide sign's white legend should be clearly visible and the background should be recognizable as green). If not, replace the sign.

- If inspection takes place after leaves have dropped and tree limbs fall within the view of the sign, but do not obscure sign: trim limbs to account for the time when leaves will regrow

- Inspection vehicles should be typical cars, SUVs or pickups, 2002 or newer

- Two-person inspection crews for safety

- Inspection conducted from travel lane (not shoulder) and conducted at normal travel speed

- Headlights should be cleaned before inspection begins. Clouded or hazed lenses should be polished

- Headlights should be checked to ensure they are properly aimed.

Signs shall be visible from the following distances:

- Flat Sheet Signs must be visible from approximately 300 ft to provide drivers enough time to see and react to the sign. Any deficiencies which prohibit a sign from being seen at this minimum distance shall be identified in the inspection and corrected.

- Structural Signs (Extruded Panel Substrate) must be visible and legible from a minimum of approximately 300 ft. on two-lane roadways and 600 ft. on multilane highways (based on 30 ft. visibility for every 1 in. of legend height, per EPG 903.2.15 Word Messages).

Issues that can affect sign visibility and shall be corrected are, but are not limited to:

- Sign sheeting which has fallen below acceptable performance levels

- Vegetation or other obstructions blocking the view of the sign

- Sign installation location, requiring sign to be moved to a better more visible location

- Damage to the sign face, such as gun shots, paint ball or other vandalism activities

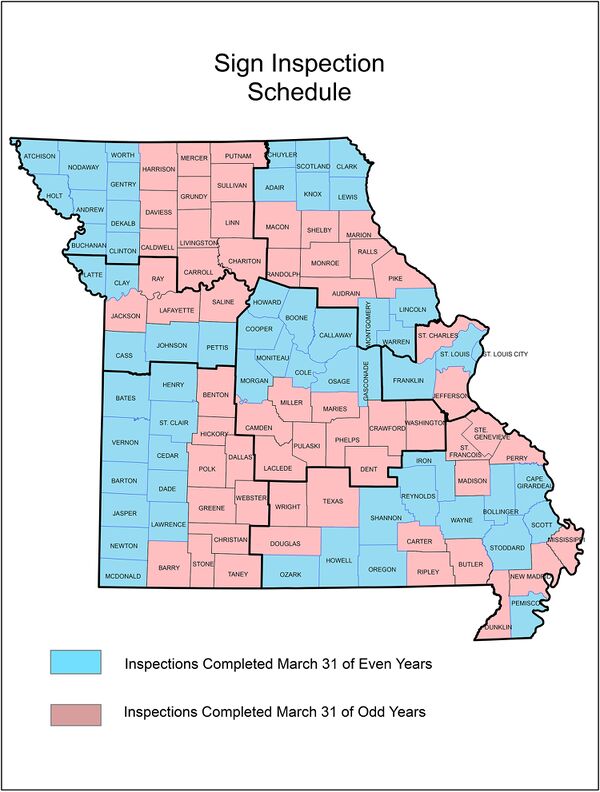

Sign posts shall be within acceptable tolerances of being vertically plumb (see Figure 903.2.22.2, below) and must hold the sign perpendicular to the travel way unless the sign type and installation intentionally requires the sign to be parallel to the roadway. Sign posts out of plumb and not supporting the sign in the proper orientation to the roadway shall be repaired or replaced as necessary.